Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

The XSTM series Pneumatic large heat press is an outstanding press machine for large-scale production. As the large heat press Microtec produced, the XSTM series owns 4 sizes: 80x100cm, 100x120cm, 120x170cm and 150x250cm. You can choose the size per your needs.

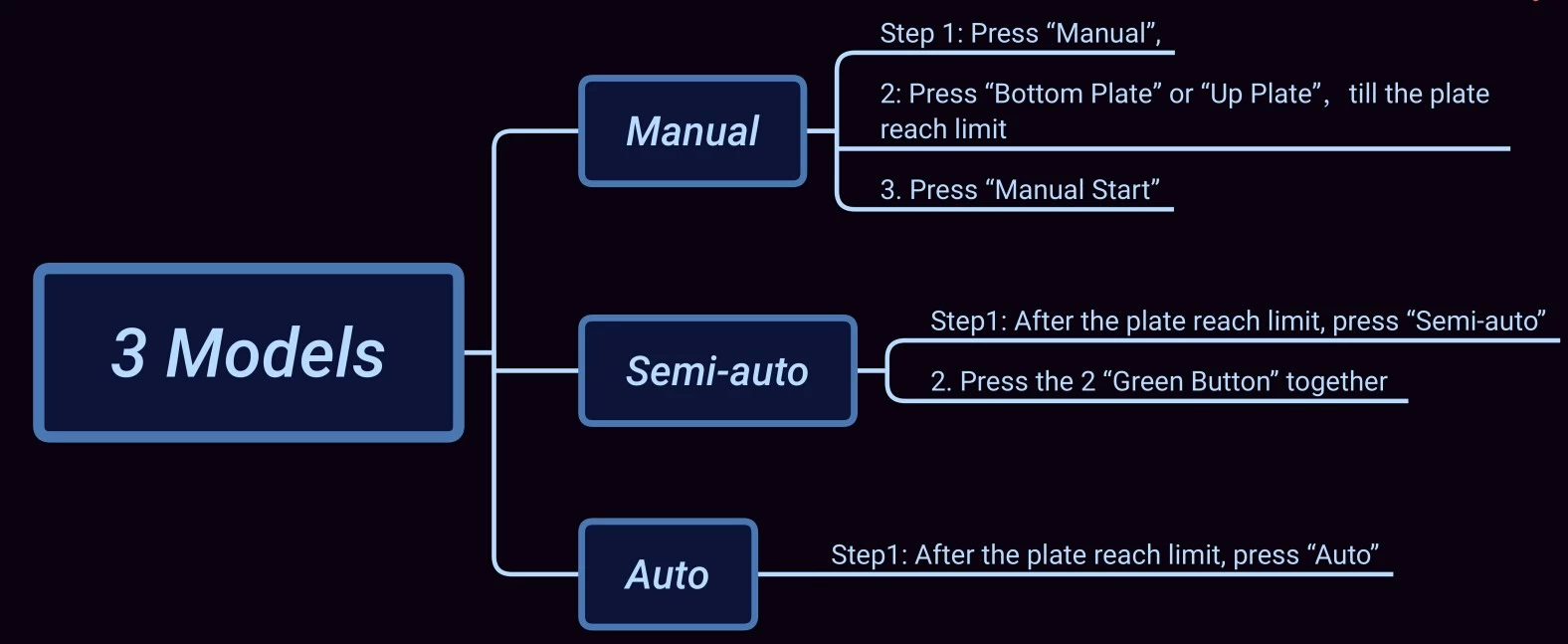

Microtec XSTM heat press features powerful air cylinders, an reciprocating dual tray system, and three operation models.

For XSTM large format heat press, it is an idea to sublimation textile, cloth, flag, raincoat, umbrella, metal sheet etc large format material. The air cylinders offer very high pressure, which makes sure excellent transfer results. With reciprocating dual tray system, it speeds up your production, save your footprint, and reduce your labor; Only one worker is ok to operate this dual heat press machine. And you can choose manual, semi-automatic and fully automatic production models.

1) XSTM Series large heat press adopts pluggable heat elements: there are separate heat tubes in the platen, and if there is any one broken, you can only change the one tube easily. No need to repalce the whole heat platen which is with much higher cost.

How to find out the problem of heat platen: https://www.youtube.com/watch?v=GbqDx8NONlA

How to exchange the heat platen: https://www.youtube.com/watch?v=2G-kFAbYw4g

2) XSTM Series large heat press adopts PLC digital touch screen controller: The controller can controll each heat tube temp., then the whole heat platen can have more even heat.

More PLC controller info: https://www.heatpress.cn/news/Upgraded-PLC-digital-touch-screen.html

This large heat press is ideal for maximizing the efficiency of your facilities and maintaining stable quality.

|

PLC Touch Screen Digital Controller: Equipped with a PLC digital touch screen controller, this heat press allows precise control of each heat tube's temperature. This ensures uniform heat distribution across the entire platen, promoting consistent and high-quality transfers. |

|

Upgraded Pluggable Heat Elements: The platen incorporates separate heat tubes, enabling easy replacement of individual tubes in case of malfunctions. This design eliminates the need to replace the entire heat platen, resulting in significant cost savings. |

|

Dual Working Tables for High Production: With the inclusion of two base plates on a single side, the XSTM-68 facilitates high production volumes, streamlining workflow and maximizing efficiency. |

|

Pneumatic with Air Cyclinders: That offer the higher pressure and could heat transfer aluminium sheet, wood, fabric, garment etc. Ideal for sublimation with good productivity and flexibility. |

|

Air Filter: To adjust the pressure of it, easy to operate and maintenance. |

| Model No. | XSTM-40 | XSTM-48 | XSTM-68 |

| Machine Type | Automatic, Dual Working Tables | ||

| Platen Size | 32"x40" (80x100cm) | 40"x48" (100x120cm) | 48"x68" (120x170cm) |

| Controller | High-end PLC Digital Touch Screen | ||

| Printable Articles | Up to 180mm Thickness | ||

| Air Compressor Required | 4.5kgf/c㎡ | ||

| Voltage | 220V 1Phase/ 220V 3Phase/ 380V 3Phase | ||

| Power | 5.1KW/ 7.5KW/ 12KW | ||

| |

0-999 sec. | ||

| Maximum Temp. | 225 C | ||

| Temperature Accuracy | ±0.5% | ||

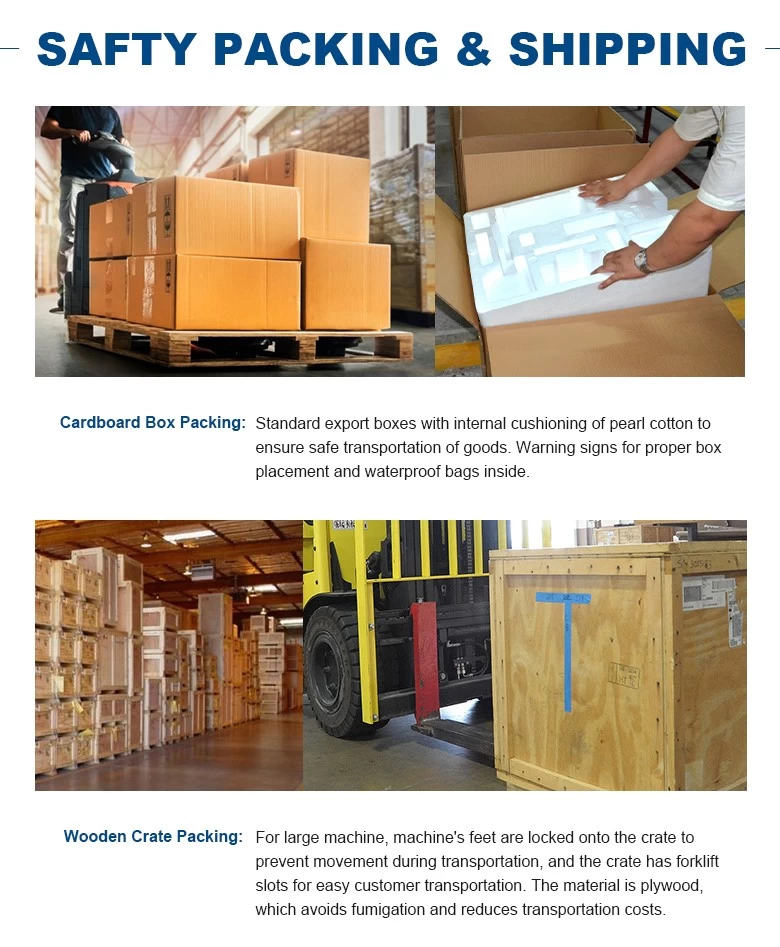

All XSTM Series Pnematic Large Heat Press Machines are well packed in wooden package and provide with manual.

The XSTM Series Large Heat Press machine is designed for a wide range of applications, making it a versatile solution for various industries. Its large format and advanced features make it ideal for:

-Sports goods, apparel production

-Advertising, flags, banners, accessories.

-Metal Sheet Sublimation, large photo, posters.

-Transfer on Hard Substrate

(ceramic, aluminum, plastic, wood...)

-Textile: home finishing, apparel, curtains…

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF