|

The unique designs of our XSTM large format heat press machine, which differentiates other large format sublimation heat press in the markets are:

1) it adopts pluggable heat elements: there are separate heat tubes in the platen, and if there is any one broken, you can only change the one tube easily. No need to repalce the whole heat platen which is with much higher cost.

How to find out the problem of heat platen: https://www.youtube.com/watch?v=GbqDx8NONlA

How to exchange the heat platen: https://www.youtube.com/watch?v=2G-kFAbYw4g

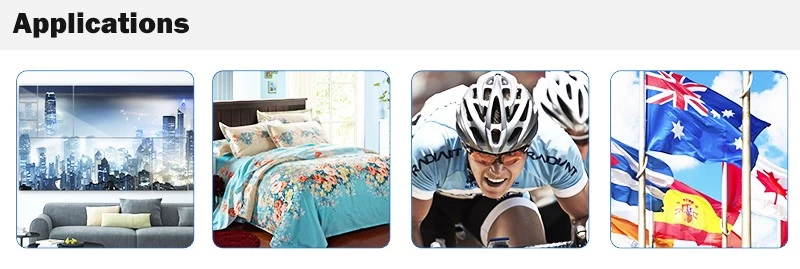

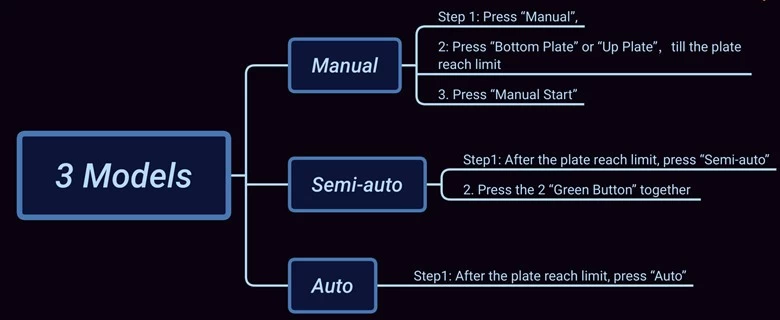

2) it adopts PLC digital touch screen controller: The controller can controll each heat tube temp., then the whole heat platen can have more even heat.

More PLC controller info: https://www.heatpress.cn/news/Upgraded-PLC-digital-touch-screen.html

This large heat press is ideal for maximizing the efficiency of your facilities and maintaining stable quality.

|

PLC Touch Screen Digital Controller: Equipped with a PLC digital touch screen controller, this heat press allows precise control of each heat tube's temperature. This ensures uniform heat distribution across the entire platen, promoting consistent and high-quality transfers. |

|

Upgraded Pluggable Heat Elements: The platen incorporates separate heat tubes, enabling easy replacement of individual tubes in case of malfunctions. This design eliminates the need to replace the entire heat platen, resulting in significant cost savings. |

|

Dual Working Tables for High Production: With the inclusion of two base plates on a single side, the XSTM-98 facilitates high production volumes, streamlining workflow and maximizing efficiency. |

|

Pneumatic with Air Cyclinders: That offer the higher pressure and could heat transfer aluminium sheet, wood, fabric, garment etc. Ideal for sublimation with good productivity and flexibility. |

|

Air Filter: To adjust the pressure of it, easy to operate and maintenance. |

|