Established in 2001, Microtec is occupying the leading position in the field of Heat Presses, Sublimation Blanks as well as DTF and UV Printers in China. With profound research, development and innovation over the past 20 years, Microtec has been growing from a trading company to a leading manufacturer of heat press machines and DTF & UV Printers. The Factory occupies more than 28000 square meters, has more than 280 employees. It possesses 6 workshops for manufacturing Heat Press Machines, 2 dust-free labs for producing coated mugs, plates and tiles etc, 2 workshops for DTF Printers and UV Printers. As an expert in its field, Microtec is renowned for the quality and reliability of its products and unrivalled customer support.

Our company has passed ISO9001:2008 quality system certification, and access to vital product certifications like CE Certificates for Heat Presses and DTF Printers, FDA Report and US Proposition 65 for Ceramic Mugs, etc. That is to say, all the products we provide excess the Chinese national standard and meet European & International safety standard.

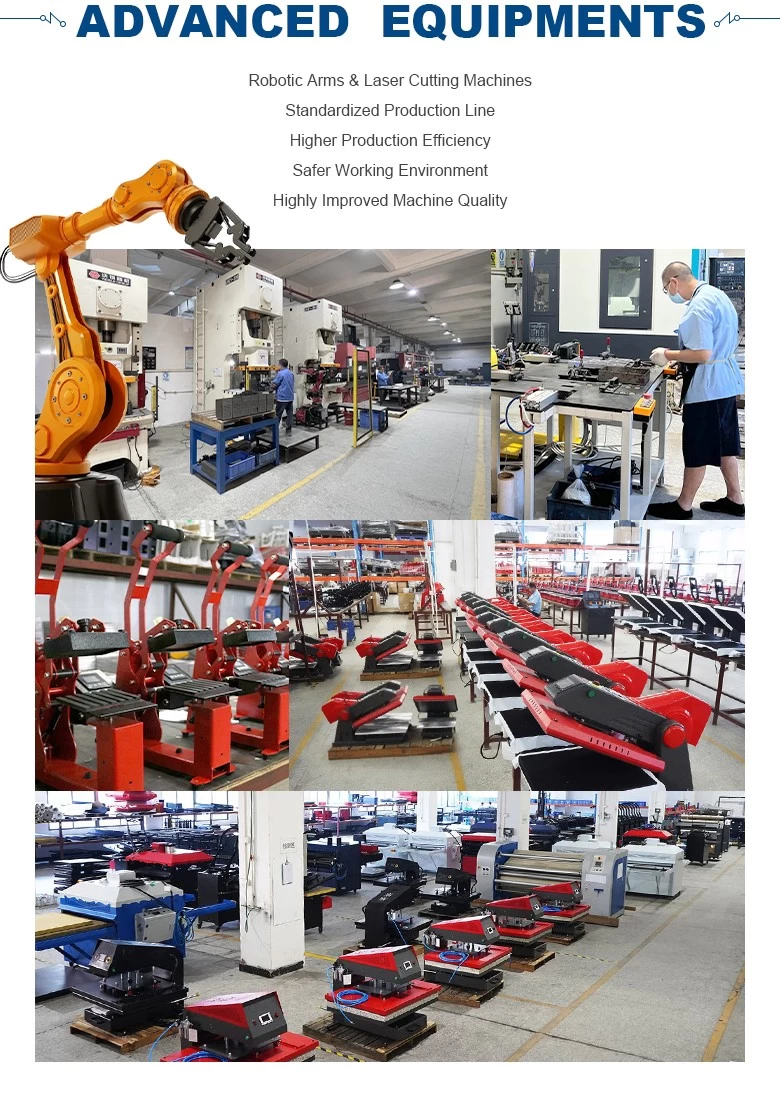

We spent most to be well-equipped in view of meeting the high requirement of production and quality. For instance, the heavyweight, our Laser Cutting Machine can be used to cut the mould and design all the machine accessories like our ECH combo series so as to make its' apperance be unique among the counterparts; and the rare Gantry Milling Machine cutting a more even heat platen in straight line to ensure a constant temperature, the Bending Machine making the welding in a digital control way and some other ancillary equipment.

Microtec is consistently dedicated to high standard of produce technology and processing levels to return customer and gain market share.Taking the heat platen of the machine for example, we adopted Die-casting technic and have heat platens made of Aluminum titanium alloy instead of the common iron in the market, thus innovated the heat platen characterized with pretty high pressure, longer temperature-constant and lower temeperature-difference (within 5 degrees in the entire platen). All these help to ensure our machines work with hot-speel transfer easily. Most of all, all our machines can do Plastisol Heat Transfer with prefect image.

Moreover, all the heat platens are baked on Teflon coat in High-temperature Industrial Oven under 200 degree Celsius for 30 minutes. Make sure the platens are Scratch-resisitant and long usage life.

Besides, all the iron parts of our machine are anti-rust handled before using them to produce machine. In this way, all our machines are rusty free for more than one year, even in a very wet environment.

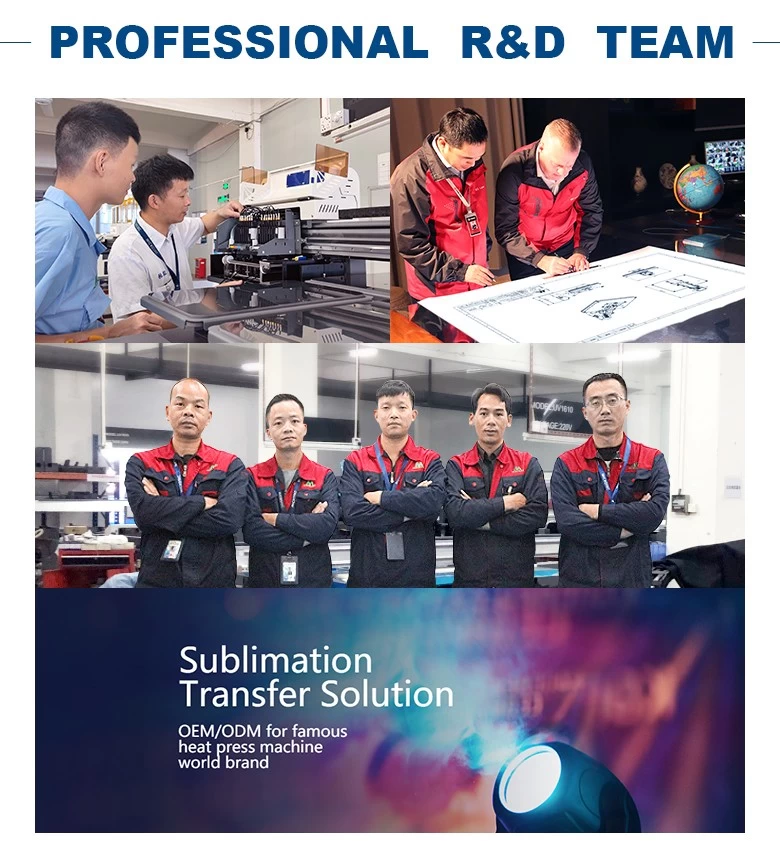

Microtec firmly believes that customer's need always comes first, then we pay more attention to research and development. Our strong R&D team keeps learning the new technology and lauching the improvement for our machines these years, like adding particular functions, improving a particular part and even developing new model machines. Microtec will keep going to provide various new innovative products to meet customers' needs.

Quality control is also attached more importance by us. For your information, every spare parts of our machine, especailly for the heat platen should be tested strictly before assembling to the machine; all the machines are strictly tested twice under 200 degree Celsius for 20 minutes before shipping to customers. And there also will be testing report for each machine which can be found in the package.

Microtec provides one-stop service for our customers. For one thing, we have our own export right. So, it is possible for us to handle and supervise customers's goods shipment in a more convenient and safed way; for another, our products ranges from Heat Press Machine to Sublimation blanks like mugs, plates, etc. Then, customers can source all the relative products in one factory. Save time, save money, and gain much convenience.

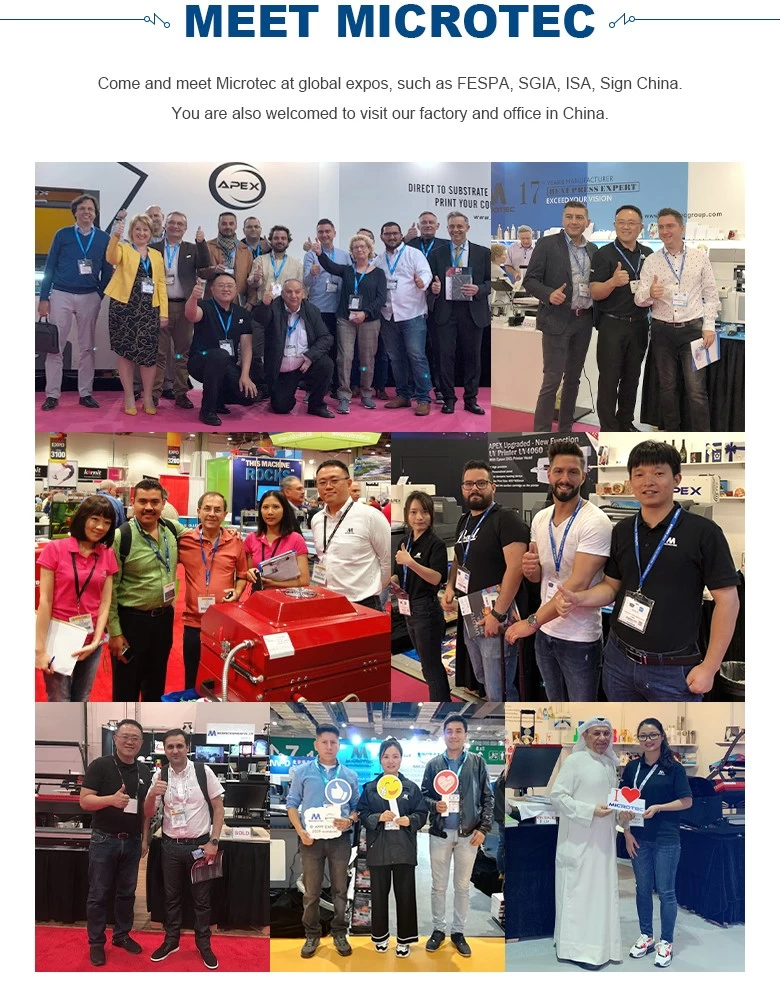

Microtec sells all over the world and occupies a large market in different countries. We provide OEM and ODM service with superior quality. Distributor is available in USA, Germany, Italy, France, UK, Australia etc for heat presses. All in all, our constantly expanding network of agents and distributors spanning over 70 countries on six continents means you will be supported by one of the largest and most responsive customer service organisations within the industry.