Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

For large-scale production needs, the PSTM series sublimation heat press machine by Microtec stands as a formidable choice. As a leader in the realm of large format heat presses, the PSTM heat press offers versatility with three available sizes: 80x100cm (32"x40"), 100x120cm (40"x48"), and 120x170cm (48"x68"). With the added advantage of dual working tables, it significantly enhances your production capacity.

What sets the PSTM heat press machine apart is its evolution from the ASTM series. Notably, the PSTM employs a finely crafted aluminum heat platen with individual plug-in heat tubes. This innovative design contributes to superior temperature control and even heat distribution. Additionally, maintenance is simplified, as you can replace faulty heating tubes individually, rather than the entire heat platen.

Operating as a pneumatic press with an air cylinder, the PSTM heat press machine provides excellent pressure and heat transfer capabilities. While it occupies a middle-tier position in our pneumatic heat press lineup, it excels in minimizing color variation when transferring thin materials like cloth, especially when compared to our high-end XSTM heat presses. Moreover, the PSTM demonstrates remarkable proficiency in transferring thicker materials, including wood, ceramic tiles, photo slates, and more.

Distinguishing itself from the PSTM-S variant, the PSTM heat press machine boasts a double working station, elevating productivity for your business.

Rest assured, the safety and quality of our press machines adhere to stringent CE standards, ensuring continuous quality control. Additionally, all spare parts have received UL certifications, reinforcing our commitment to delivering reliable and safe equipment to our valued customers.

The Microtec PSTM Large Heat Press Machine offers a range of attractive features that cater to the needs of large-scale production. Here are some of its standout features:

Three Size Options: Choose from three size options - 80x100cm (32"x40"), 100x120cm (40"x48"), and 120x170cm (48"x68") - to accommodate a variety of printing projects.

Individual Plug-In Heat Tubes: Utilizes a fine aluminum heat platen with individual plug-in heat tubes for even heat distribution and easy maintenance, as you can replace faulty heating tubes individually, reducing downtime and costs.

Dual Working Tables: Equipped with two working tables, it significantly enhances production capacity and workflow efficiency.

Pneumatic Operation: Operates as a pneumatic press with an air cylinder, ensuring consistent and powerful pressure for excellent heat transfer results.

Versatile Material Compatibility: Excellently transfers designs onto both thin materials like cloth and thicker materials such as wood, ceramic tiles, and photo slates.

ASTM Series Evolution: Builds on the success of the ASTM series, offering improved features and capabilities for large-format heat pressing.

Color Consistency: Minimizes color variation, making it ideal for applications where accurate color reproduction is crucial.

Safety Assurance: Complies with CE standards, ensuring permanent control of safety and quality, providing peace of mind to operators.

|

GY-06 Touch Screen Controller: Equipped with a digital control panel that allows you to set and adjust both temperature and time. This precise control is essential for achieving the best results with different materials and transfers. |

|

Double Working Station: With two separate stations, allowing for simultaneous printing on two different items or locations. This feature significantly increases productivity. |

|

Pneumatic Heat Press with Two Cyclinders: That offer the higher pressure, ideal for sublimation metal boards, sportsware with good productivity and flexibility. |

|

Individual Plug-In Heat Tubes: Utilizes a fine aluminum heat platen with individual plug-in heat tubes for even heat distribution and easy maintenance, as you can replace faulty heating tubes individually, reducing downtime and costs. |

|

Advanced Heat Platen: Utilizes a fine aluminum heat platen with individual plug-in heat tubes for precise temperature control and even heat distribution. |

| Model No. | PSTM-40/ PSTM-48/ PSTM-68 |

| Machine Type | Automatic, Double Station, Individual Plug-In Heat Tubes |

| Platen Size | 32"x40"/40"x48"/48"x68" (80x100cm/100x120cm/120x170cm) |

| Controller | GY-06 Digital Time & Temp. Control |

| Printable Articles | Up to 20mm Thickness |

| Air Compressor Required | Yes |

| Voltage | 220V 1phase/ 220V 3phase/ 380V 3phase |

| Power | 5.1KW/ 7.5KW/ 9KW |

| Time Range | 0-999 sec. |

| Maximum Temp. | 225 C |

| Temperature Accuracy | ±0.5% |

| High Pressure | 8kg/cm |

| Packing Size | 182x138x176/ 204x157x177/ 241x156x176cm |

| Net Weight | 425kg/ 536kg/ 641kg |

| Gross Weight | 604kg/ 764kg/ 900kg (Wooden Package) |

| Tips | Price include machine, 2pcs of teflon sheets, repair kits, not include air compressor (3HP) |

PSTM large format heat press machine is suitable for a wide range of applications, including heat transfers onto apparel, sportsware, flags, sublimation printing on textiles, and heat-pressing various promotional products and personalized gifts.

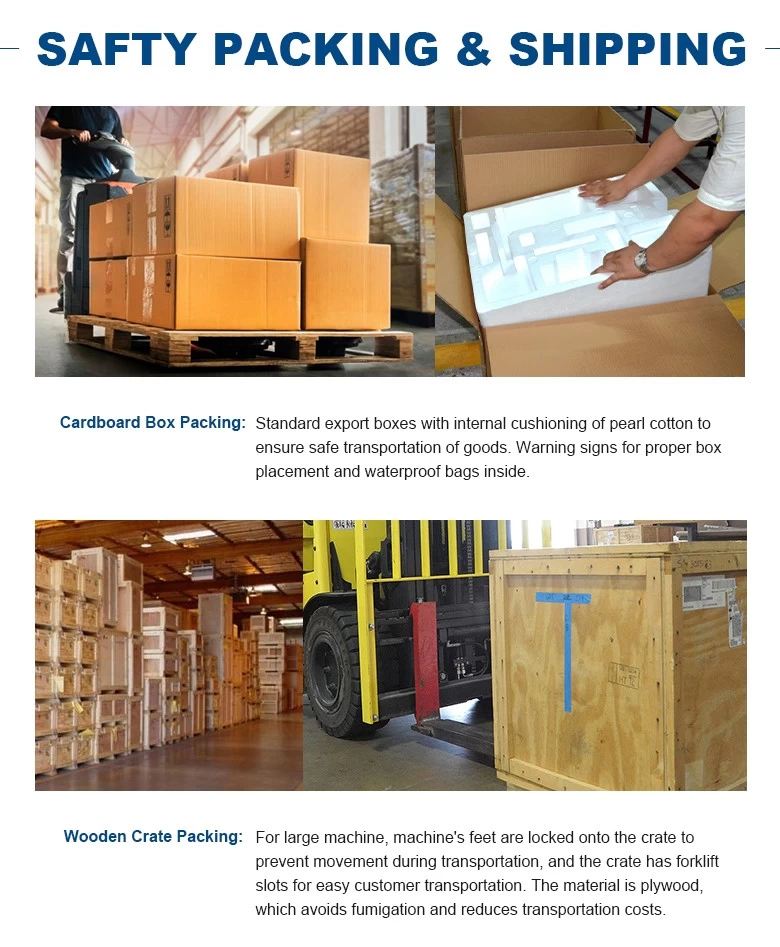

All Microtec Pneumatic Large Format Heat Press is well-packed in wooden package and provide with manual.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF