Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

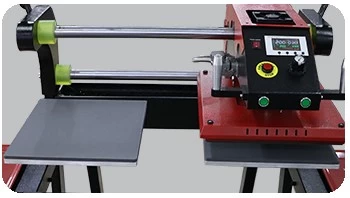

DEMON 45 Pneumatic Dual Station Shuttle Heat Press with Floor Stand & Infrared Positioning Device is a versatile and high-performance heat transfer machine designed for businesses and individuals engaged in heat pressing applications. This heavy-duty heat transfer press, offers a range of features and benefits that make it an ideal choice for anyone looking to create custom designs on various substrates with precision and efficiency.

DEMON 45 Dual Shuttle Press key features:

Double Station for Enhanced Productivity: This heat press is equipped with two working stations, allowing for increased productivity. You can load one station while the other is in operation, reducing downtime and increasing efficiency. It's an excellent choice for businesses with high production demands.

Pneumatic Operation: The press utilizes a pneumatic system for smooth and consistent pressure application. This ensures even and high-quality heat transfers onto a wide range of materials.

Shuttle Mechanism: The shuttle sliding design enables easy loading and unloading of substrates, making it suitable for high-volume production. You can seamlessly switch between the two stations with minimal effort.

Infrared Positioning Device: The built-in infrared positioning device helps you precisely align your transfer materials, ensuring accurate and consistent printing results. This feature is especially beneficial for multi-color or multi-layer designs.

Floor Stand: The included floor stand provides stability and convenience. It allows for easy placement and adjustment of the heat press, making it suitable for various working environments.

Digital Control Panel: The intuitive digital control panel offers user-friendly settings for time and temperature, making it easy to customize the heat transfer process for different materials.

Wide Application Range: This dual shuttle heat press is suitable for a variety of substrates, including garments, textiles, ceramics, and more. It's perfect for creating custom apparel, promotional products, and personalized gifts.

|

GY-06 Touch Screen Digital Controller: The intuitive digital control panel offers user-friendly settings for time and temperature, making it easy to customize the heat transfer process for different materials. |

|

Double Shuttle Station: Demon 45 is a shuttle type pneumatic dual station heat transfer printing machine, equipped with 2pcs of 40x50cm base plates. Pneumatic drive, easy to operate, save time & effort. The dual station design also improves production efficiency. |

|

Equipped with Floor Stand: The included floor stand provides stability and convenience. It allows for easy placement and adjustment of the heat press, making it suitable for various working environments. |

|

Dual Trays for Transfer Material Placement: With a tray dedicated to each station, you can seamlessly load and prepare your transfer materials while one station is in operation. This minimizes downtime and optimizes your workflow, leading to higher productivity. |

|

Pressure Adjustment: Pressure adjustment device is installed on the operation panel, and the pressure can be adjusted by pulling up and twisting knob. |

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF