Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

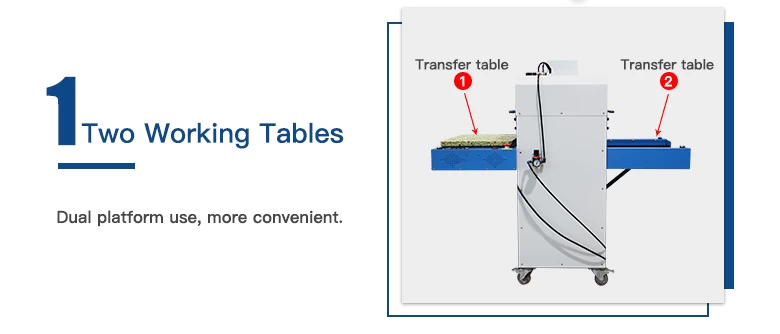

The ASTM-24 Pneumatic Heat Press Machine stands out with its impressive 16"x24" (40x60cm) double working station and air-operated system. This pneumatic heat press machine is designed for production-oriented pressing, featuring push-button operation, fully digital temperature and time control, and a robust steel welded frame. All these features are offered at an affordable price, making it an excellent choice for large format automatic heat pressing.

Key Features of the 16"x24" Double Station Pneumatic Heat Press:

Industrial-Grade Construction:

Combines a heavy-duty solid industrial-grade framework with high-quality electric components for durability and reliability.

Smooth Drawer-Style Motion:

Operates with a smooth front-loading motion, enhancing efficiency and ease of use during production.

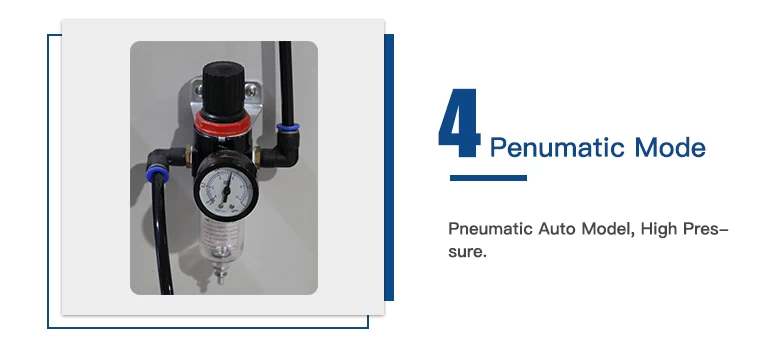

High-Pressure Pneumatics:

Utilizes top-down pneumatics with fully adjustable PSI control, ensuring consistent and precise pressure during heat pressing.

Fully Digital Temperature & Time Control:

Features a fully digital control system for temperature and time, providing accuracy and convenience in operation.

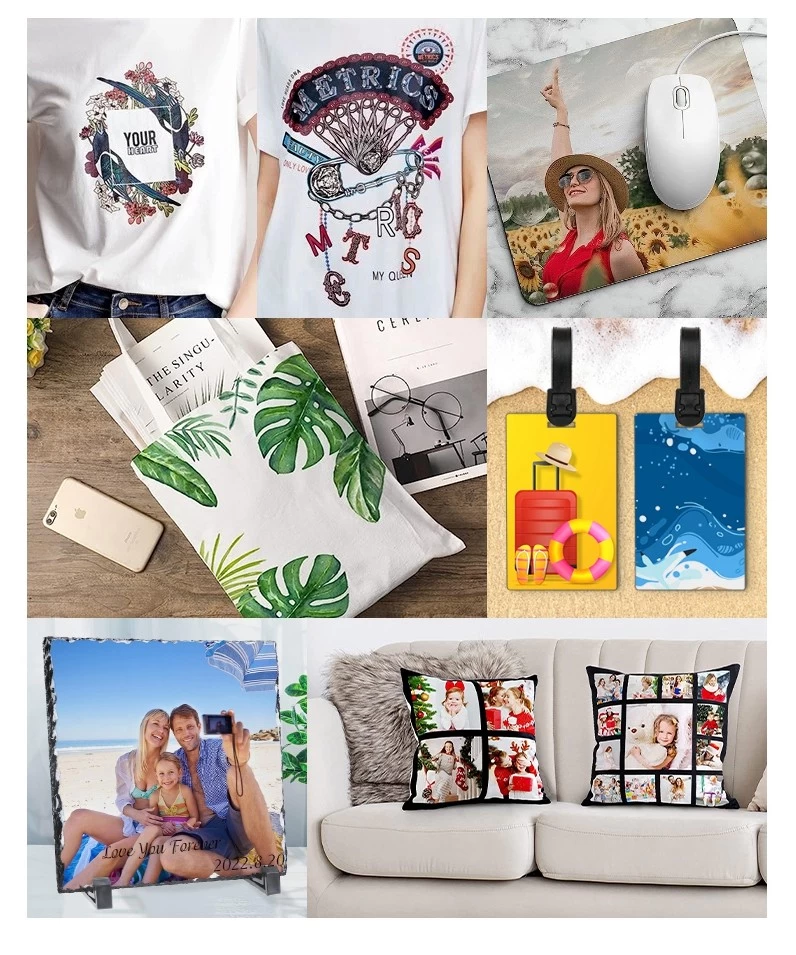

Versatile Sublimation Applications:

Perfect for heat transfer pressing on a wide range of materials, including fabric, complex garments, metal, wood, ceramics, glass, and more.

Industrial-Grade Automatic Solution:

Positioned as an industrial-grade automatic solution that bridges the gap between smaller platens and large-format heat presses.

The ASTM-24 automatic heat press machine is an ideal solution for businesses requiring efficient and precise heat transfer on various materials. Its dual working stations, air-operated system, and user-friendly features make it a reliable and cost-effective choice for large-format automatic heat pressing applications.

| Model No. | ASTM-24 |

| Machine Type | Automatic, Double Station |

| Platen Size | 16"x24" (40x60cm) |

| Under Plate | Slide-out |

| Controller | GY-06 Digital Time & Temp. Control |

| Printable Articles | Up to 50mm Thickness |

| Air Compressor Required | Yes |

| Voltage | 120V/ 220V |

| Power | 1600W/ 1800W |

| Time Range | 0-999 sec. |

| Maximum Temp. | 225 C |

| Packing Size | 148x93x148cm |

| Gross Weight | 278kg (Wooden Package) |

ASTM-24 Double station pneumatic heat press is ideal for heat transferring onto large fabric pieces and metal photo panels, like Banners, sportsware, metal boards, cushions etc.

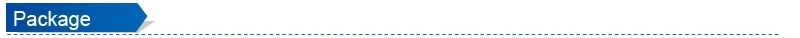

Microtec Pneumatic Large Format Heat Press is well-packed in wooden package and provide with manual.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF