Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

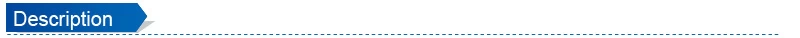

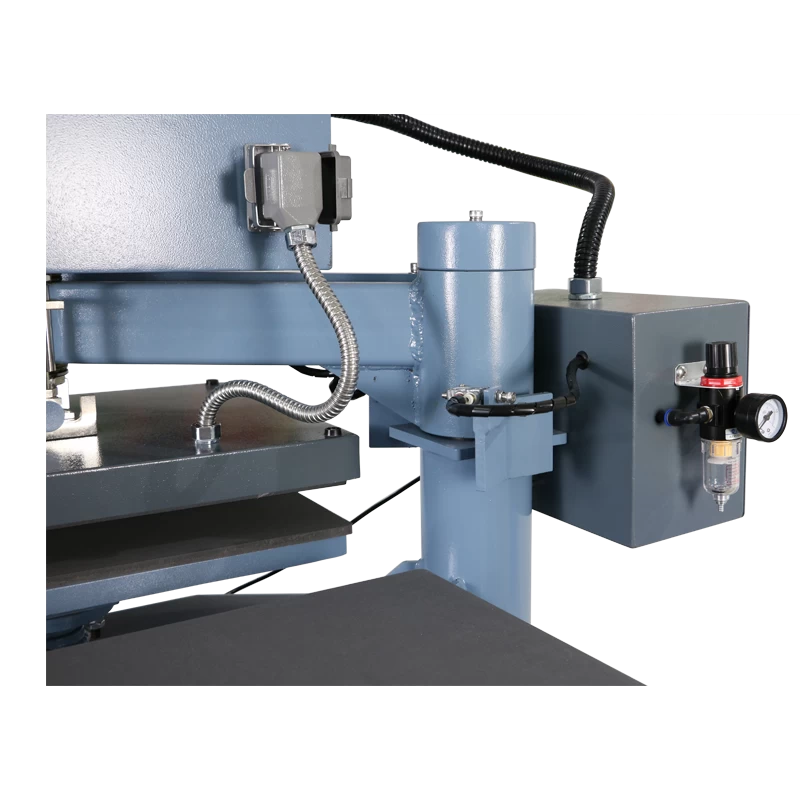

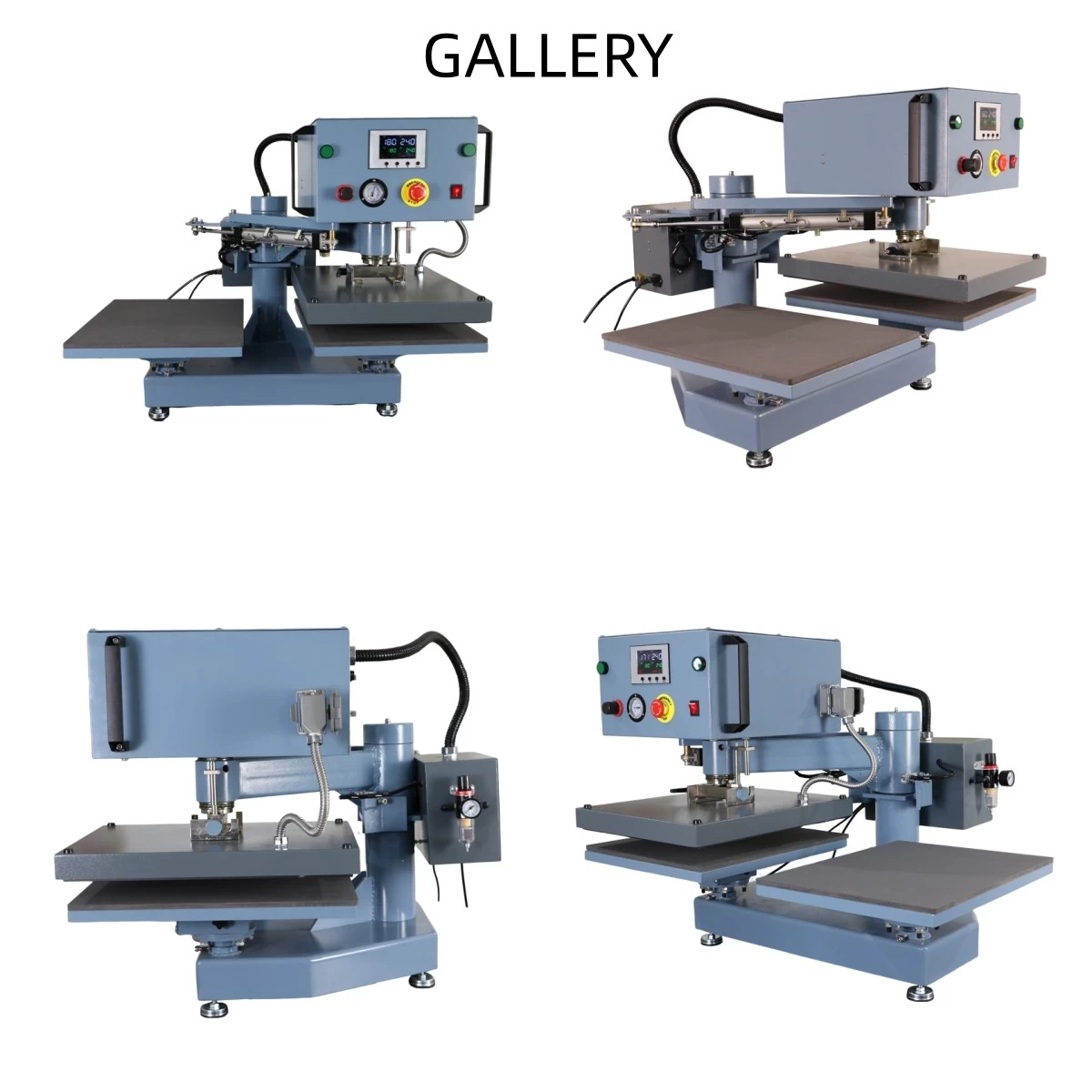

Microtec Air-operated Dual Station Shuttle Heat Press Omega 1000, a high-performance, pneumatically operated heat press designed for demanding, high-volume production environments. With its unique double table feature, operators can seamlessly prepare the next item for pressing while the first table is in action.

The pneumatic operation guarantees precise and consistent pressure on every press cycle, reducing operator fatigue and thereby enhancing overall productivity while minimizing errors caused by exhaustion.

Safety is at the forefront of the Omega Series 1000 Press, featuring a range of excellent safety measures.

Pressure is easily adjusted by means of a straightforward air pressure gauge and secure locking air pressure control. The Omega 1000 Dual Station Shuttle Heat Press machine offers full customization of time and temperature settings through its intuitive controller, with error messages displayed in case of any faults.

Omega 1000 Pneumatic Dual Shuttle Heat Press key features:

Omega 1000 Pneumatic Dual Shuttle Heat Press key features:

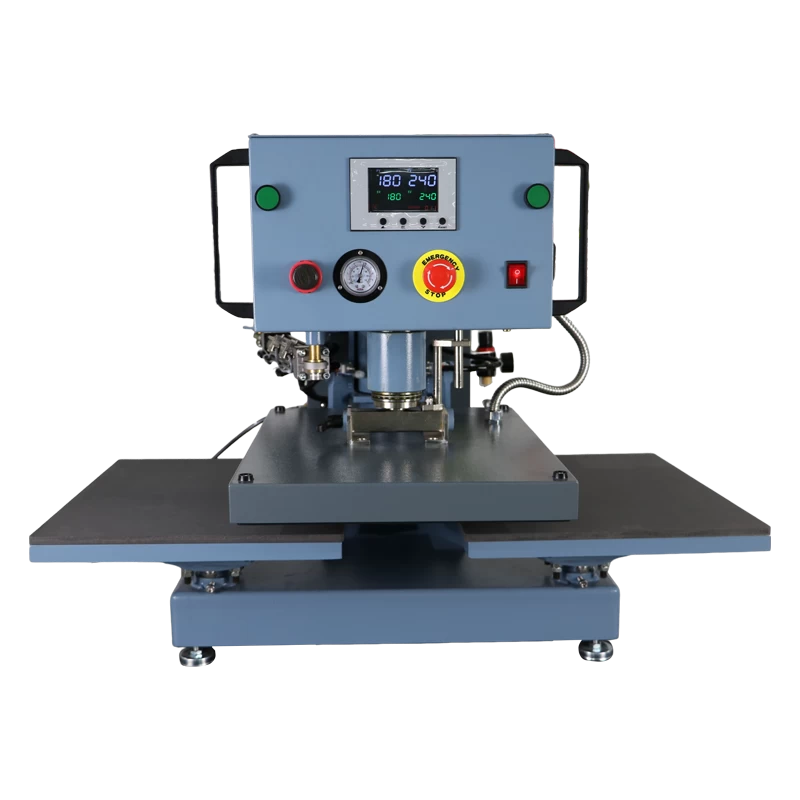

Pneumatic Precision: Operated using advanced pneumatic technology, ensuring consistent and precise pressure on every press cycle.

Double Table Efficiency: Equipped with a double table feature, allowing operators to prepare the next item for pressing while the first table is in use, optimizing workflow in high-volume production environments.

Operator-Friendly Design: Minimizes operator fatigue, enhancing productivity and reducing the likelihood of errors due to exhaustion.

Safety First: Incorporates multiple safety features, including a twin-button control system to keep operators' hands clear of the pressing area, an emergency stop button for prompt shutdown, and a mechanism ensuring the heat plate only operates when properly aligned over the lower table.

Temperature Control: Features an inbuilt thermal cut-out on the heating element that automatically cuts off power if the temperature exceeds 235°C +/- 15°C (455°F +/- 27°F), ensuring safe operation.

User-Adjustable Pressure: Offers user-friendly control with a simple air pressure gauge and locking air pressure mechanism for easy pressure adjustment.

Customizable Settings: Fully adjustable time and temperature settings through an intuitive controller, with error message display in case of any faults, providing flexibility for various production needs.

Compact Footprint: Requires minimal operating space, making it suitable for a range of production environments.

Compliance and Safety Standards: Manufactured and rigorously tested to comply with EC safety regulations, proudly bearing the CE label.

High-Volume Production Ready: Designed to meet the demands of very high volume production environments, ensuring efficiency and reliability.

These key features highlight the Omega Series 1000 Press's advanced capabilities, operator-friendly design, and commitment to safety and complianc

|

Pneumatic Precision: Operated using advanced pneumatic technology, ensuring consistent and precise pressure on every press cycle. |

|

Double Table Efficiency: Equipped with a double table feature, allowing operators to prepare the next item for pressing while the first table is in use, optimizing workflow in high-volume production environments. |

|

Safety First: Incorporates multiple safety features, including a twin-button control system to keep operators' hands clear of the pressing area, an emergency stop button for prompt shutdown, and a mechanism ensuring the heat plate only operates when properly aligned over the lower table. |

|

Compact Footprint: Requires minimal operating space, making it suitable for a range of production environments. |

| Model No. | Omega 1000 |

| Machine Type | Automatic, Dual Station, Shuttle Press |

| Platen Size | 15"x20" (38x50cm) |

| Controller | GY-06 LED Digital Control |

| Max. Air Supply | 6 bar max. (87 Psi) |

| Compressed Air Consumption | 40Litres/min |

| Voltage | 230-240V |

| Power |

2.5kW

|

| Time Range | 0-999 sec. |

| Maximum Temp. | 225 C |

| Temperature Accuracy | ±5 C |

| Packing Size | 107x95x110cm |

| Gross Weight | 182Kg (Wooden Package) |

The Omega 1000 Pneumatic Double Station Shuttle Heat Press is versatile, catering to a diverse array of uses. It excels at applying heat transfers onto clothing, sublimation printing on textiles, and pressing a variety of promotional items.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF