Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

APDS Pneumatic Double Station Shuttle Heat Press Machine is a versatile and efficient piece of equipment for customizing a wide range of items with heat transfers andsublimation. Its dual station design, high pressure, precise controls, safety features, and even heat distribution make it an excellent choice for businesses involved in heat printing and customization.

APDS Pneumatic Dual Shuttle Heat Press key features:

Double Station Design: This heat press machine is equipped with two separate stations, allowing for simultaneous printing on two different items or locations. This feature significantly increases productivity.

Pneumatic Operation: The machine operates using a pneumatic system, which means it uses compressed air to apply consistent and even pressure to the heat platen. This ensures uniform heat distribution and excellent print quality.

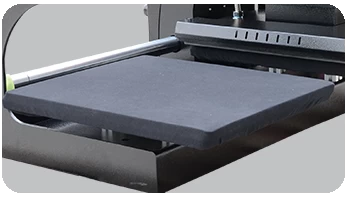

16''x20'' Heat Platen: The heat platen, the surface where heat and pressure are applied, measures 16 inches by 20 inches. This size is ideal for a wide range of applications, including T-shirt printing, heat transfers, and more.

Sliding Feature: The sliding feature allows for easy loading and unloading of materials. It simplifies the placement of items to be pressed, reducing the risk of errors and ensuring precise positioning.

Digital Temperature and Time Control: The machine is equipped with a digital control panel that allows you to set and adjust both temperature and pressing time. This precise control is essential for achieving the best results with different types of materials and transfers.

Adjustable Pressure: You can easily adjust the pressure settings to accommodate various materials and thicknesses, ensuring that the heat transfer adheres correctly without damaging the fabric or substrate.

Automatic Timer: The built-in timer will automatically stop the pressing process when the preset time is reached. This feature prevents overexposure to heat, which can be detrimental to certain materials.

Safety Features: APDS-20 comes with safety features such as an emergency stop button and heat-resistant handles to ensure the safety of the operator.

Sturdy Construction: The machine is typically constructed with a durable frame and high-quality components, ensuring long-lasting performance and reliability.

Even Heat Distribution: The heat platen is designed to distribute heat evenly across its surface, minimizing the risk of hot spots and ensuring consistent, high-quality transfers.

|

GY-06 Touch Screen Digital Controller: Equipped with a digital control panel that allows you to set and adjust both temperature and pressing time. This precise control is essential for achieving the best results with different types of materials and transfers. |

|

Double Stations Design: Offered with two separate stations, allowing for simultaneous printing on two different items or locations. This feature significantly increases productivity. |

|

Even Heat Distribution: The heat platen is designed to distribute heat evenly across its surface, minimizing the risk of hot spots and ensuring consistent, high-quality transfers. |

|

Sturdy Construction: APDS-20 is typically constructed with a durable frame and high-quality components, ensuring long-lasting performance and reliability. |

|

Adjustable Pressure: You can easily adjust the pressure settings to accommodate various materials and thicknesses, ensuring that the heat transfer adheres correctly without damaging the fabric or substrate. |

| Model No. | APDS-15/ APDS-20 |

| Machine Type | Automatic, Shuttle, Double Station |

| Platen Size | 15"x15"/ 16"x20"(38x38cm/ 40x50cm) |

| Under Plate | Quick Exchangeable |

| Controller | GY-06 Digital Time & Temp. Control |

| Printable Articles | Up to 32mm Thickness |

| Air Compressor Required | Yes |

| Voltage | 120V/ 220V |

| Power | 1450W/ 1800W |

| Time Range | 0-999 sec. |

| Maximum Temp. | 225 C |

| Temperature Accuracy | ±0.5% |

| Packing Size | 121x99x75cm |

| Gross Weight | 151kg/ 160kg(Wooden Package) |

APDS Pneumatic Double Station Shuttle Heat Press is suitable for a wide range of applications, including heat transfers onto garments, sublimation printing on textiles, and heat-pressing various promotional products like mugs, caps, and more.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF