Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

Microtec New Multifunctional Oil Heating MTX series Rotary Thermal Transfer Machine has been specifically designed to meet the increasing demand for cut piece digital printing. This is one roll to roll heat transfer printing machine that makes transferring any large job quick and easy. It is an inexpensive, easy to manage solution for all your dye sublimation paper transfer applications. This rotary heat transfer machine can be used for transferring on continuous or roll materials.

The new oil heating system guarantees a uniform heat distribution across the width of the drum with a minimum of energy consumption. This system uses 50% less energy than electrically heated presses. Microtec 44'' Calender rotary heat press is ideal for transferring high quality images onto polyester fabrics, image Roll-to-Roll and cut sheet applications such as dye sub banners, soft signages, displays, cut and sew dye sub, sportswear, fitness garments and more.

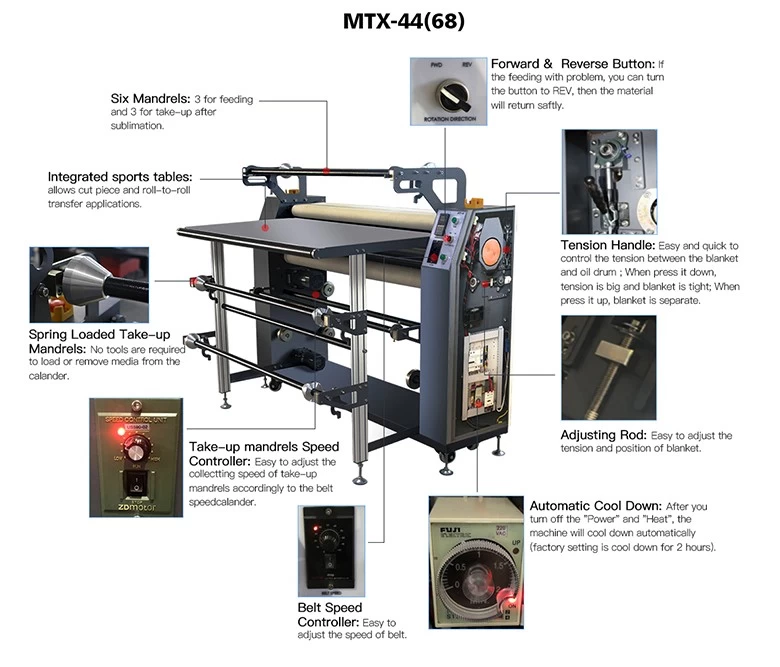

Microtec MTX calenders are an affordable, easy to use solution for all your dye sublimation paper transfer applications. MTX calenders deliver precision temperature fixation to a broad range of textile applications, thus saving time on production. An all steel solid construction provides high quality performance and ensures. MTX calenders are built for year on year production.  Integrated sports tables: allows cut piece and roll-to-roll transfer applications Six mandrels: 3 for feeding and 3 for take up after sublimation Spring Loaded take-up Mandrels: No tools are required to load or remove media from the calander. Forward & Reverse Button: if the feeding with problem, you can turn the button to REV, then the material will return saftly. Tension Handle: Easy and quick to control the tension between the blanket and oil drum ; When press it down, tension is big and blanket is tight; When press it up, blanket is separate. Adjusting Rod: Easy to adjust the tension and position of blanket. Belt Speed Controller: Easy to adjust the speed of belt. Take-up mandrels Speed Controller: Easy to adjust the collectting speed of take-up mandrels accordingly to the belt speed. Automatic cool down: After you turn off the "Power" and "Heat", the machine will cool down automatically (factory setting is cool down for 2 hours).

* 1 year warranty for the machine * Lifetime online support on machine maintenance.  Sublimation Application: TEXTILES, FURNISHING, FASHION-SPORTSWEAR-PROMOTIONAL, FILMS ROLL to ROLL: calenders for printing continuous and reel-wound materials PIECE to ROLL: special calenders capable of operation in both modes (material in cut pieces and/or in rolls) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF