Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

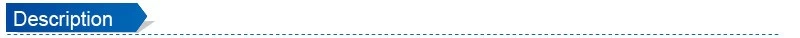

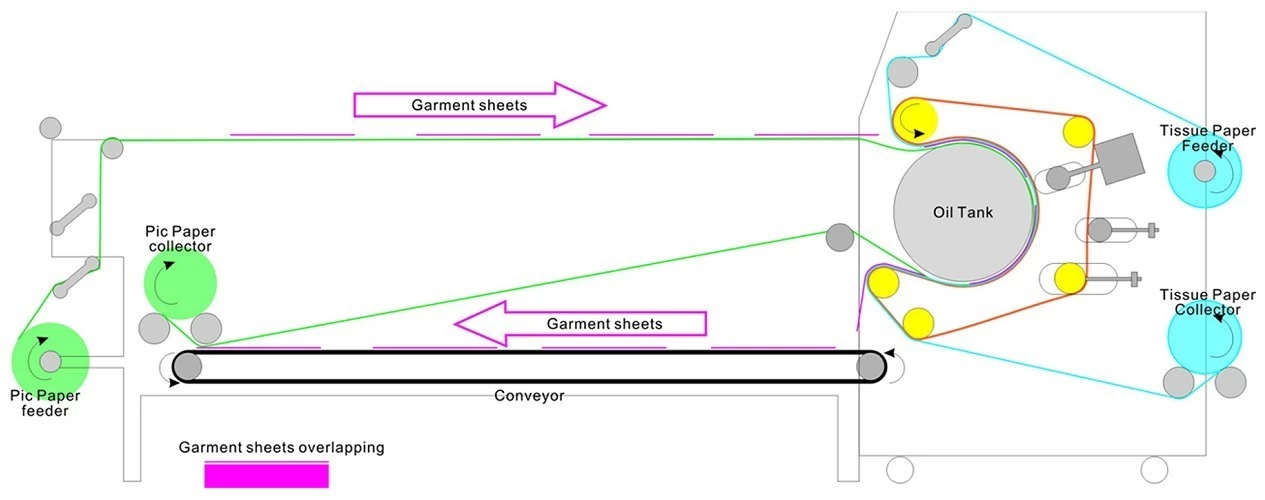

MTP Multifunctional Oil Heating Rotary Thermal Transfer Machine is suitable for thermal & low temperature transferring. With stable temperature output, duplex oil tank and precise mechanical structure, it is very good for torary thermal transfer. The adjustable air pressure control system is perfect for rotary transferring too.

The Roll-to-roll system makes printed materials in parallel without deflection, blanket can be separated from oil tank manually when power failure and also can do cut-piece heat transfer.

MTP Multifunctional Oil Heating Rotary Thermal Transfer Machine is applied for Garment sheets / Fabric rolls/ Flags/ Socks/ Blanket/ Curtain etc

|

Digital Controller: Seperate temperature control and tranform speed control; It is easy for you to set the time, temperature and speed. More accurate of the time and temp. display |

|

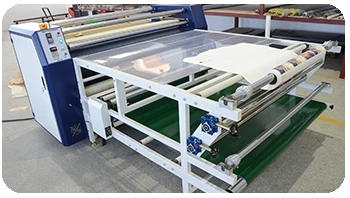

Machine with blanket table:No cooling machine is needed and the blanket can be separated from the oil tank. Easy to do Roll to Roll or cut-piece |

|

Emergency button: Stop machine when meet emergency |

|

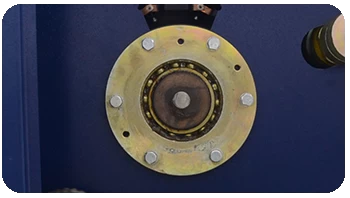

High-quality bering: This bearing makes the press machine work smoothly and safely; |

| Model No. | MTP-1700 | MTP-2500 | MTP-3200 | |

| Machine Type | Roll Type, Oil Heating, Multifunctional | |||

| Quality Level | High-level model, Multifunction | |||

| Heating Media | Oil | |||

| Heating Power | 18KW | 30KW | 36KW | |

| Number of Heating Elements | 12 | |||

| Diameter of Drum | 420mm | |||

| Transfer Speed | up to |

|||

| Max Temperature | 260C | |||

| Transfer Width | 1650mm | 2450mm | 3150mm | |

| Blanket Width | 1730mm | 2530mm | 3300mm | |

| Process Path | Feeding in through bottom drum | |||

| Function of Roll to Roll | Y | |||

| Function of Sheet to Sheet | Y | |||

| Number of Feeding Rollers | 3 | |||

| Number of Collecting Rollers | 2 | |||

| Workable Included | Y | |||

| Air Pressure Included | Y | |||

| Machine Dimension(cm) | 247*98*132 | 329*105*140 | 401*105*140 | |

| Workable Size(cm) | 186*192*100 | 266*192*100 | 336*192*100 | |

| Packing Size(cm) | 260*130*165 | 360*140*170 | 430*140*170 | |

| Net Weight | 1380kgs | 1700kgs | 2100kgs | |

| Gross Weight | 1450kgs | 1900kgs | 2300kgs | |

Various of roll fabrics, flag, wall fabric, curtains, bedding, cushion, umbrella, belt and individual design

Microtec's main objective is to support all our customers, who can manage their heat transfer activities without interruption. So Microtec offers FREE SPARE PARTS with a quantitative order and the following guarantee:

* Free lifetime technical support on all heat press machines.

* Two-year warranty

* Five-year warranty on fusions and welds.

* Five-year warranty on the heating plate.

* Six-monthly warranty on the heaters of cups, plates and caps.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF