Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

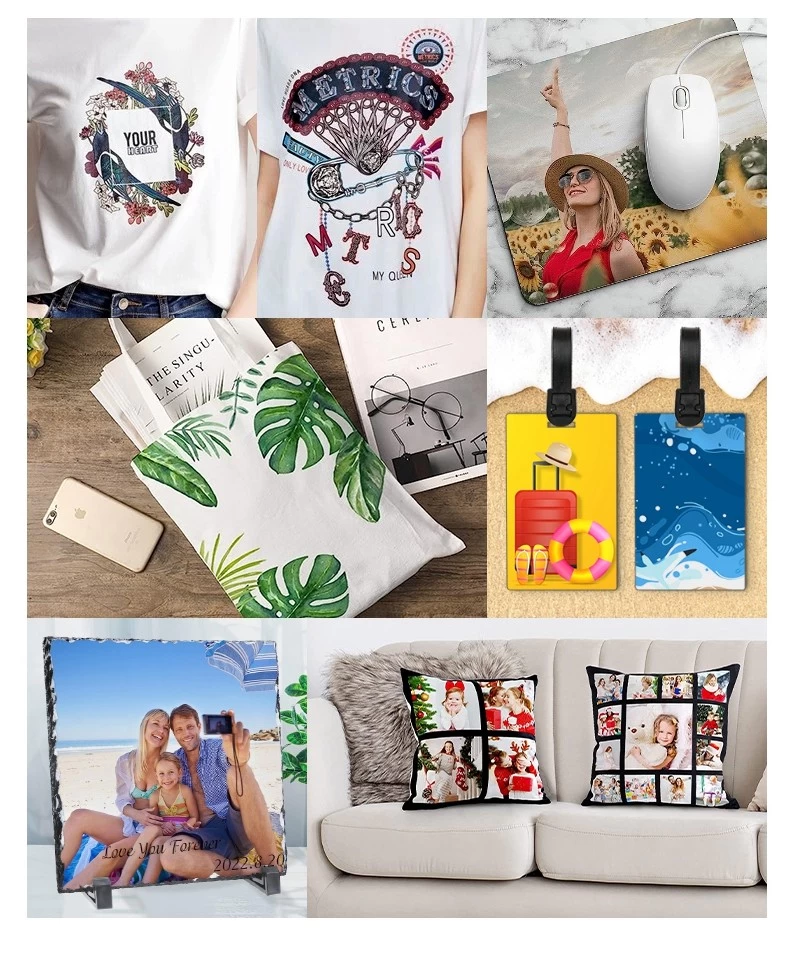

APDS-15 (3838cm) and APDS-20 (4050cm) Pneumatic Heat Press Machine by Microtec, a professional-grade double base plate heat transfer press designed for precision and accuracy. With its two workstations, this heat press provides an exceptionally generous working area, facilitating comfortable positioning of transfer objects.

Key Features of the APDS Pneumatic Heat Press:

Compact Size with Dual Working Stations:

A perfect choice for those seeking a small-sized heat press with high pressure and the convenience of two working stations.

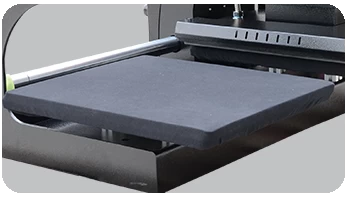

Versatile Applications:

Ideal for transferring Toner paper, HD metal prints, photo slates, and more, offering versatility in applications.

Smooth Movement of Heating Plate Head:

The heating plate head smoothly moves from one side to the other, enhancing operational efficiency.

Quick Change of Spare Parts:

The sublimation heat press machine is designed for ease of use, allowing for quick and hassle-free changes of spare parts.

Whether you're working with T-shirts heat transfer, HD metal prints, photo slates, or other sublimation materials, the APDS Pneumatic Heat Press is an excellent choice. Its compact size, high pressure, and dual working stations make it a versatile and efficient solution for a range of heat transfer applications.

|

GY-06 Digital Controller: Equipped with GY-06 digital controller that allows you to set and adjust both temperature and pressing time. This precise control is essential for achieving the best results with different types of materials and transfers. |

|

Smooth Movement of Heating Plate Head: The heating plate head smoothly moves from one side to the other, enhancing operational efficiency. |

|

Heating Element with Soft Silicone: With the soft silicone, the heat and pressure can be distributed more even, to get perfect transfer result. |

|

Vertical Contact Pressure: The pneumatic head of the heat plate provides vertical contact pressure, facilitating flawless transferring of various materials without displacement effects. |

|

Air Filter: To adjust the pressure of APDS double station heat press machine, easy to operate and maintenance. |

| Model No. | APDS-15/ APDS-20 |

| Machine Type | Automatic, Shuttle, Double Station |

| Platen Size | 15"x15"/ 16"x20" (38x38cm/ 40x50cm) |

| Controller | GY-06 Digital Time & Temp. Control |

| Printable Articles | Up to 32mm Thickness |

| Air Compressor Required | Yes |

| Voltage | 120V/ 220V |

| Power | 1450W/ 1800W |

| Time Range | 0-999 sec. |

| Maximum Temp. | 225 C |

| Packing Size | 121x99x75cm |

| Gross Weight | 151kg/ 160kg(Wooden Package) |

APDS Pneumatic Heat Press Machine is ideal for heat transferring onto T-shirts, sportsware, and metal photo panels, Banners, cushions, mouse pads, puzzles, sublimation ornaments etc.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF