Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

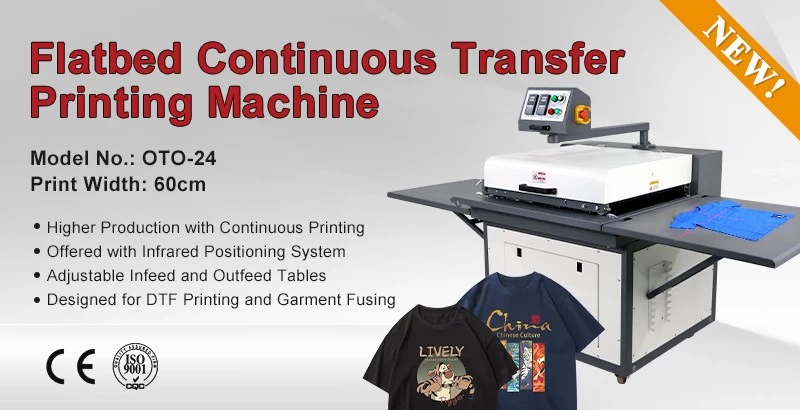

Introducing our latest innovation, the Continuous Heat Press Machine - a cutting-edge device designed to revolutionize the heat transfer process for DTF (Direct-to-Fabric) and HTV (Heat Transfer Vinyl) products, enabling seamless printing on T-shirts and other garments. Building upon the foundation of the continuous fusing machine, this improved version offers enhanced productivity and efficiency, making it an indispensable tool for businesses in the textile printing industry.

Introducing our latest innovation, the Continuous Heat Press Machine - a cutting-edge device designed to revolutionize the heat transfer process for DTF (Direct-to-Fabric) and HTV (Heat Transfer Vinyl) products, enabling seamless printing on T-shirts and other garments. Building upon the foundation of the continuous fusing machine, this improved version offers enhanced productivity and efficiency, making it an indispensable tool for businesses in the textile printing industry.

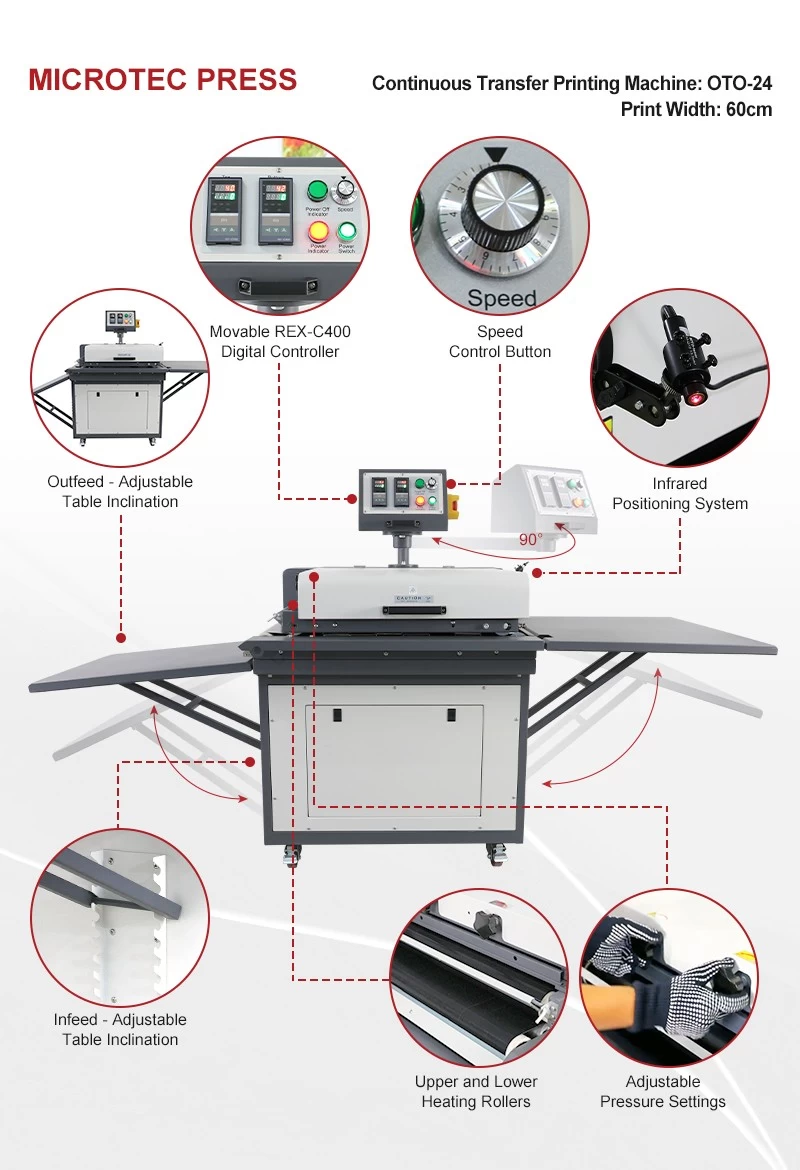

OTO-24 is a versatile transfer printing machine that allows for continuous printing. It has a width of 60cm and can accommodate materials of any length. The machine is equipped with two workstations, one for feeding the material and the other for receiving the printed output. The height of both workstations is adjustable, allowing for customization based on different printing scenarios.

Continuous Operation: The OTO-24 Flatbed Continuous Transfer Printing Machine enables uninterrupted production, maximizing productivity and reducing downtime, which is essential for businesses seeking to boost efficiency.

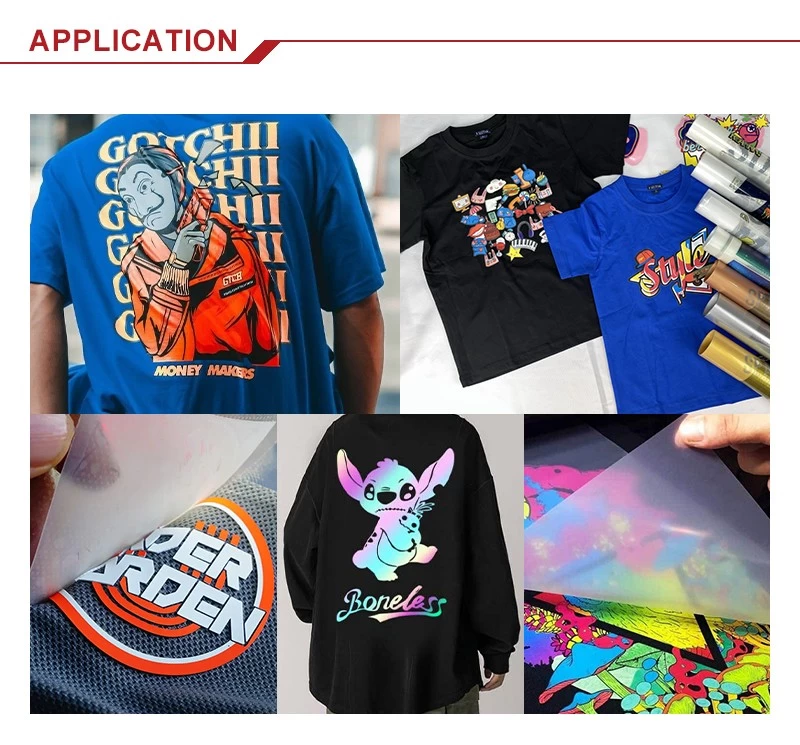

Versatility: This machine is compatible with both DTF and HTV products, allowing for seamless printing on a wide range of fabric materials, including T-shirts, hoodies, and more.

Dual Heating Elements: Equipped with top and bottom heating elements, the machine ensures even heat distribution and consistent pressure during the transfer process, resulting in excellent adhesion and long-lasting prints.

Dual Temperature Control: The machine features two independent temperature control panels, allowing precise heat management for the upper and lower platens, catering to the unique requirements of various fabrics and transfer materials.

User-Friendly Design: Despite its advanced capabilities, the OTO-24 Flatbed Continuous Transfer Printing Machine is designed with user-friendliness in mind, featuring intuitive controls and a clear interface for easy operation.

High-Quality Output: With its continuous operation, advanced heating elements, and precise temperature control, the machine guarantees exceptional print quality, durability, and wash resistance, meeting the demands of discerning customers.

In summary, the OTO-24 Flatbed Continuous Transfer Printing Machine is a versatile and professional solution for businesses seeking to enhance their heat transfer printing capabilities. Its continuous operation, compatibility with DTF and HTV products, dual heating elements, and user-friendly design make it a standout choice for increasing productivity, achieving superior print quality, and catering to various fabric printing needs. Embrace the future of continuous heat transfer printing with the OTO-24.

| Model No. | OTO-24 |

| Machine Type | Continuous Printing, Upper & Lower Heating |

| Controller | Movable REX-C400 Digital Control |

| Power | 7KW |

| Maximum Temp. | 200ºC |

| Temperature Accuracy | ±0.5% |

| Voltage | 220V |

| Current | 32A |

| Frequency | 50/ 60HZ |

| Net Weight | 249KG |

| Gross Weight | 407KG |

| Machine Size | 236x110x140cm |

| Carton Size | 183x119x163cm |

| Certification | CE Approval |

The Continuous Heat Press Machine is not limited to T-shirts; it can also be used for printing on a wide range of apparel items, including hoodies, sweatshirts, and more. Its versatility expands the application possibilities, catering to diverse customer demands.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF