Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

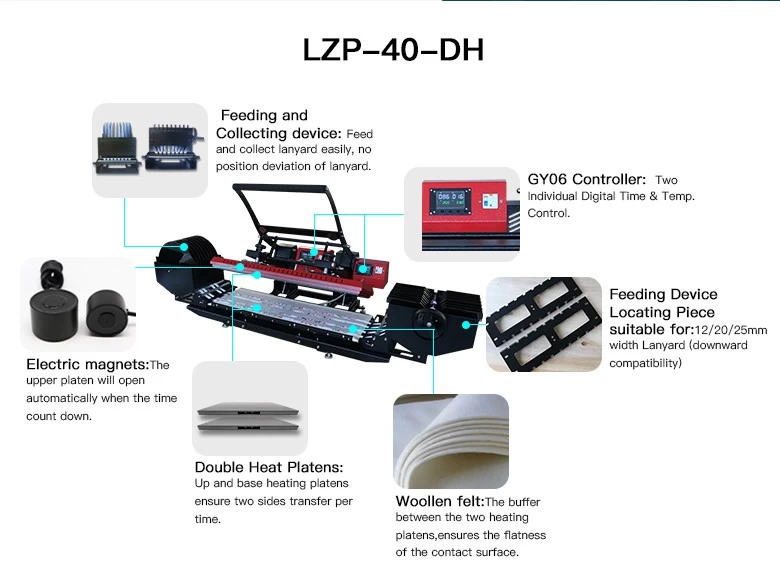

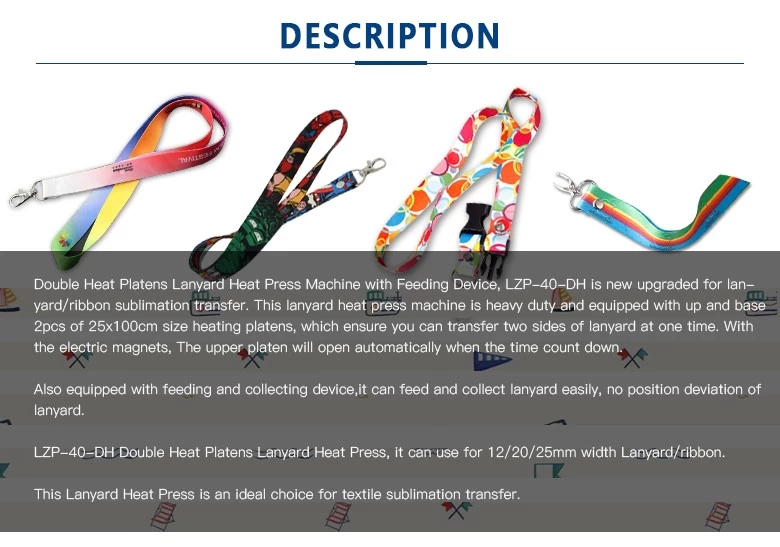

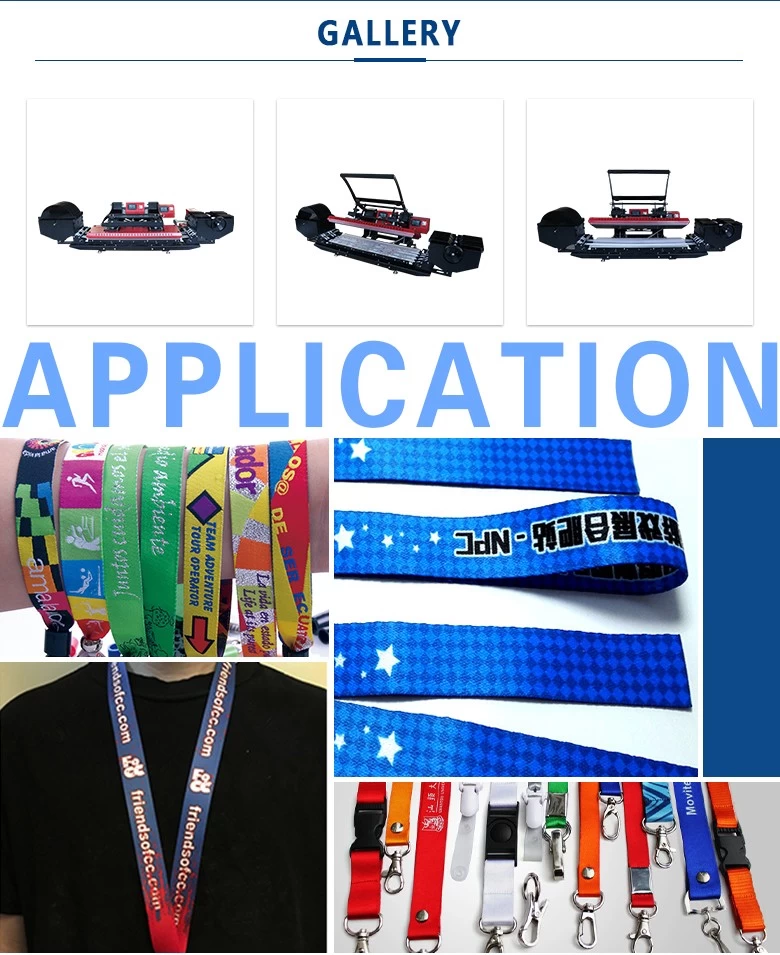

Microtec LZP-40-DH Double Heat Platens Lanyard Heat Press Machine is a high-quality heat transfer machine specifically designed for lanyard printing. This lanyard printer features dual heat platens, one on top and one on the bottom, providing even heat distribution and ensuring excellent heat transfer results. It is perfect for printing designs onto lanyards made of various materials, such as nylon, polyester, and silk.

Its main features include:

Dual heat platens: This heat press machine is equipped with two heat platens, one on top and one on the bottom, which ensures consistent and even heat distribution across the lanyard, resulting in high-quality heat transfer.

Versatile compatibility: This machine is suitable for printing designs onto lanyards made of various materials, including nylon, polyester, and silk, offering a wide range of possibilities for customization.

Precise temperature and time control: The heat press machine provides precise temperature and time control, allowing users to achieve accurate and consistent heat transfer results.

User-friendly operation: This machine is designed with user convenience in mind, featuring intuitive controls and an easy-to-read display, making it easy for users to operate and customize their printing settings.

Lanyard Printing has a big market in schools and companies, offices and external business events that will surely give you a large range of opportunities.

|

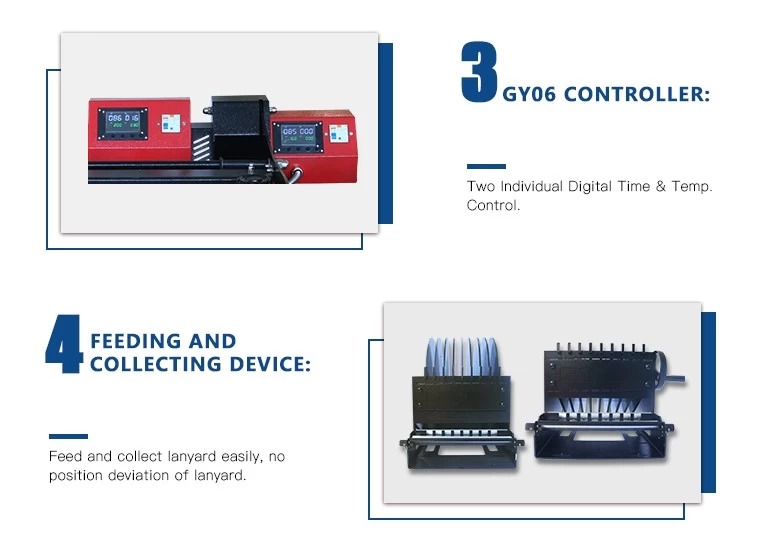

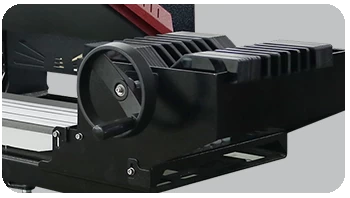

GY-06 Advanced Digital Controller: Simple design and clear display. It is easy for user to operate. Live digital time and temperature readout for accurate printing every time. |

|

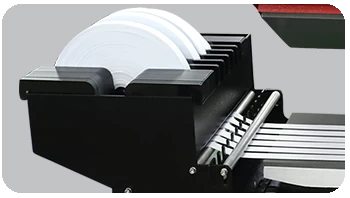

Automatic Feeding and Alignment: Equipped with a feeding device that can automatically feed and align lanyards, greatly improving efficiency and reducing labor costs. |

|

Adjustable Roller Width: The width of the roller can be adjustable, thus it can use for 12/20/25mm width Lanyard. |

|

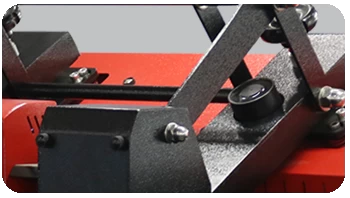

Auto-Open Release: The auto-open feature allows the heat press open automatically while finished transfer. |

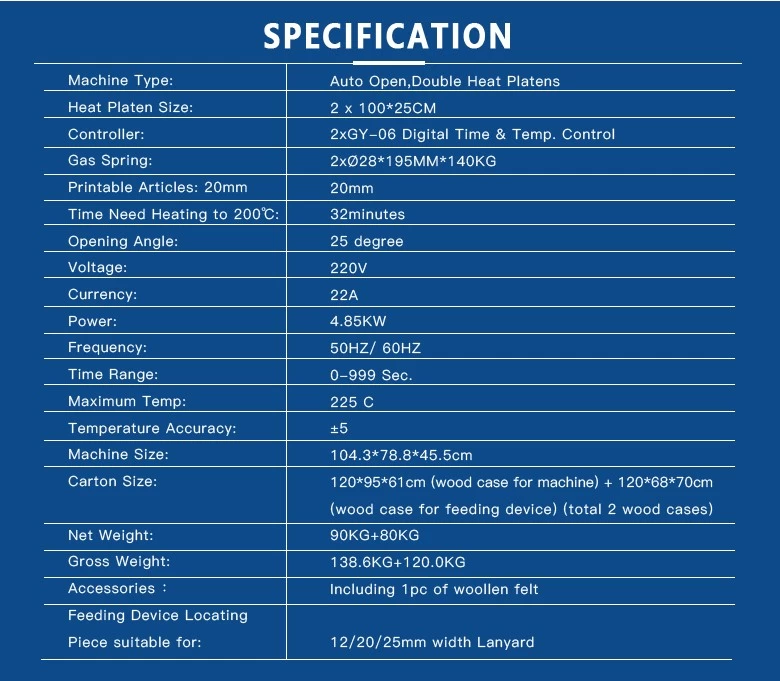

| Model No. | LZP-40-DH |

| Machine Type | Auto Open, Double Heat Platens |

| Platen Size | 2 x 100*25CM |

| Controller | 2 x GY-06 Digital Time & Temp. Control |

| Gas spring | 2 x Ø28*195MM*140KG |

| Printable Articles | 20mm |

| Time Heating to 200°C | 32 minutes |

| Opening Angle | 25 degree |

| Voltage | 220V |

| Currency | 22A |

| Power | 4.85KW |

| Frequency | 50HZ/ 60HZ |

| Time Range | 0-999 Sec. |

| Maximum Temp | 225 C |

| Temperature Accuracy | ±0.5% |

| Machine Size | 219*83*55cm |

| Carton Size | 120*95*61cm (wood case for machine) 120*68*70cm (wood case for feeding device) (total 2 wood cases) |

| Net Weight | 90KG+80KG |

| Gross Weight | 138.6KG+120.0KG |

| Accessory | Including 1pc of woollen felt |

| Suitable for | 12/20/25mm width Lanyard (downward compatibility) |

Microtec's main objective is to support all our customers, who can manage their heat transfer activities without interruption. So Microtec offers FREE SPARE PARTS with a quantitative order and the following guarantee:

* Free lifetime technical support on all heat press machines.

* Two-year warranty

* Five-year warranty on fusions and welds.

* Five-year warranty on the heating plate.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF