Lanyard Heat Press Machine with Feeding Device, LZP-40-FD is new upgraded for lanyard/ribbon sublimation. This lanyard heat press machine is heavy duty and equipped with an GY-06 Digital Controller digital timer. When the upper platen is lowered by hand, it will trip a micro switch while it closed, and the time will count down automatically.

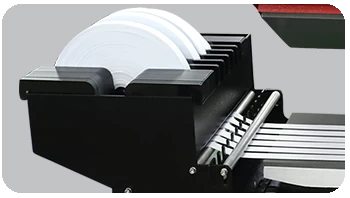

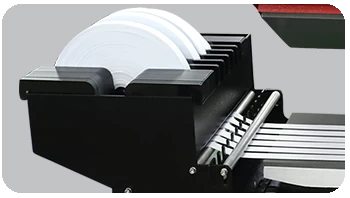

Equipped with Feeding Device that can automatically feed and align lanyards, making it a perfect solution for high-volume production of lanyards made of various materials such as nylon, polyester, and silk. It uses advanced heating technology to ensure precise and reliable heat transfer results.it can feed lanyard automatically, it is continuous collection, thus it can reduce consumption of raw material.

LZP-40-FD Lanyard Heat Press, it can use for 12/20/25mm width Lanyard/ribbon.

This Lanyard Heat Press is an ideal choice for textile sublimation printing.

|

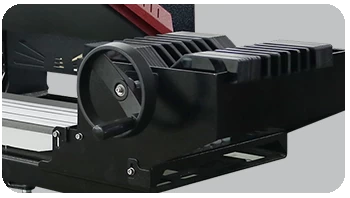

GY-06 Advanced Digital Controller: Simple design and clear system. It is very easy for user to operate. Live digital time and temperature readout for accurate results every time. |

|

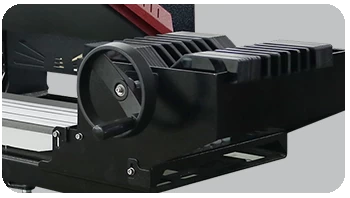

Feeding Device: Roll-to-roll feeding lanyard, it's easy for operate and help to place lanyard evenly for a better transfer effect; |

|

Adjustable Roller Width: The width of the roller can be adjustable, thus it can use for 12/20/25mm width Lanyard. |

|

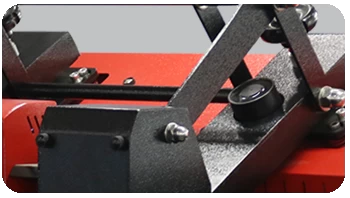

Auto-Open Release: The auto-open feature allows the heat press open automatically while finished transfer. |

| Model No. |

LZP-40-FD |

| Machine Type |

Auto Open, Lanyard Feeding Device |

| Platen Size |

100*25CM |

| Controller |

GY-06 Digital Time & Temp. Control |

| Voltage |

110V/ 220V |

| Currency |

11A/ 20A |

| Power |

2.2KW/ 2.4KW |

| Frequency |

50HZ/ 60HZ |

| Time Range |

0-999 Sec. |

| Maximum Temp |

225 C |

| Temperature Accuracy |

±0.5% |

| Machine Size |

105*79*46cm |

| Carton Size |

120*95*61cm (wood case for machine)

120*68*70cm (wood case for feeding device) (total 2 wood cases) |

| Net Weight |

90KG+80KG |

| Gross Weight |

139KG+120.0KG |

This Lanyard Heat Press Machine with Feeding Device is suitable for 12/20/25mm width Lanyard sublimation.

Microtec's main objective is to support all our customers, who can manage their heat transfer activities without interruption. So Microtec offers FREE SPARE PARTS with a quantitative order and the following guarantee:

* Free lifetime technical support on all heat press machines.

* Two-year warranty

* Five-year warranty on fusions and welds.

* Five-year warranty on the heating plate.