Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

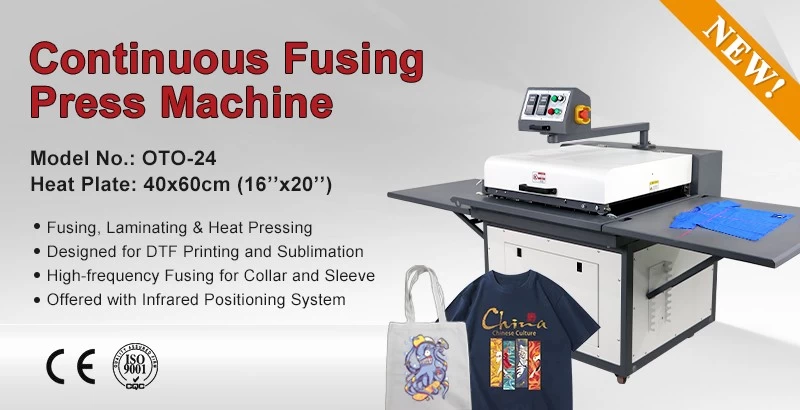

The OTO-24 is a dynamic machine that seamlessly combines continuous transfer printing with fabric fusing press capabilities. Featuring precise temperature control and steady pressure distribution, it ensures impeccable results. With moveable wheels for easy transport, it's ideal for small to medium-sized shirt manufacturers, especially for collar and sleeve fusing tasks. Efficient and adaptable, the OTO-24 empowers users to achieve professional-quality garments with ease.

The OTO-24 is a dynamic machine that seamlessly combines continuous transfer printing with fabric fusing press capabilities. Featuring precise temperature control and steady pressure distribution, it ensures impeccable results. With moveable wheels for easy transport, it's ideal for small to medium-sized shirt manufacturers, especially for collar and sleeve fusing tasks. Efficient and adaptable, the OTO-24 empowers users to achieve professional-quality garments with ease.

Versatility Redefined:

Equipped with advanced features, the OTO-24 seamlessly transitions between heat transfer printing and fabric fusing tasks. Its adaptability makes it an invaluable asset for small to medium-sized shirt manufacturers, catering to a diverse range of production needs.

Precision Engineering:

Featuring precise temperature control and steady pressure distribution on the drum, the OTO-24 guarantees consistent and reliable performance. Whether you're fusing collars, sleeves, or transferring intricate designs onto garments, this machine delivers unparalleled quality with every operation.

Ease of Mobility:

Designed with convenience in mind, the OTO-24 comes equipped with moveable wheels, making it effortlessly portable. Whether you need to reposition the machine within your workspace or transport it to different locations, its mobility ensures flexibility and ease of use.

Ideal for Collar and Sleeve Fusing:

Small to medium-sized shirt manufacturers, in particular, will find the OTO-24 indispensable for collar and sleeve fusing tasks. Its precise temperature control and steady pressure distribution guarantee optimal bonding, resulting in professional-quality garments that meet the highest standards.

Enhanced Efficiency:

By streamlining fabric fusing processes, the OTO-24 enhances efficiency and productivity, allowing manufacturers to meet tight deadlines without compromising on quality. Its versatile functionality and user-friendly design make it a must-have tool for any textile production facility.

Unlock Your Potential:

Experience the next level of fabric fusing and heat transfer printing with the OTO-24 Multi-Functional Continuous Transfer Printing Machine. Whether you're looking to fuse collars and sleeves or create stunning designs on garments, this versatile solution empowers you to unleash your creativity and achieve unparalleled results.

In summary, the OTO-24 isn't just your typical Continuous Transfer Printing Machine; it's a multifaceted powerhouse designed to excel in various fabric fusing applications. With its ability to provide steady pressure distribution on the drum, coupled with precise temperature control, this machine ensures impeccable results, every time.

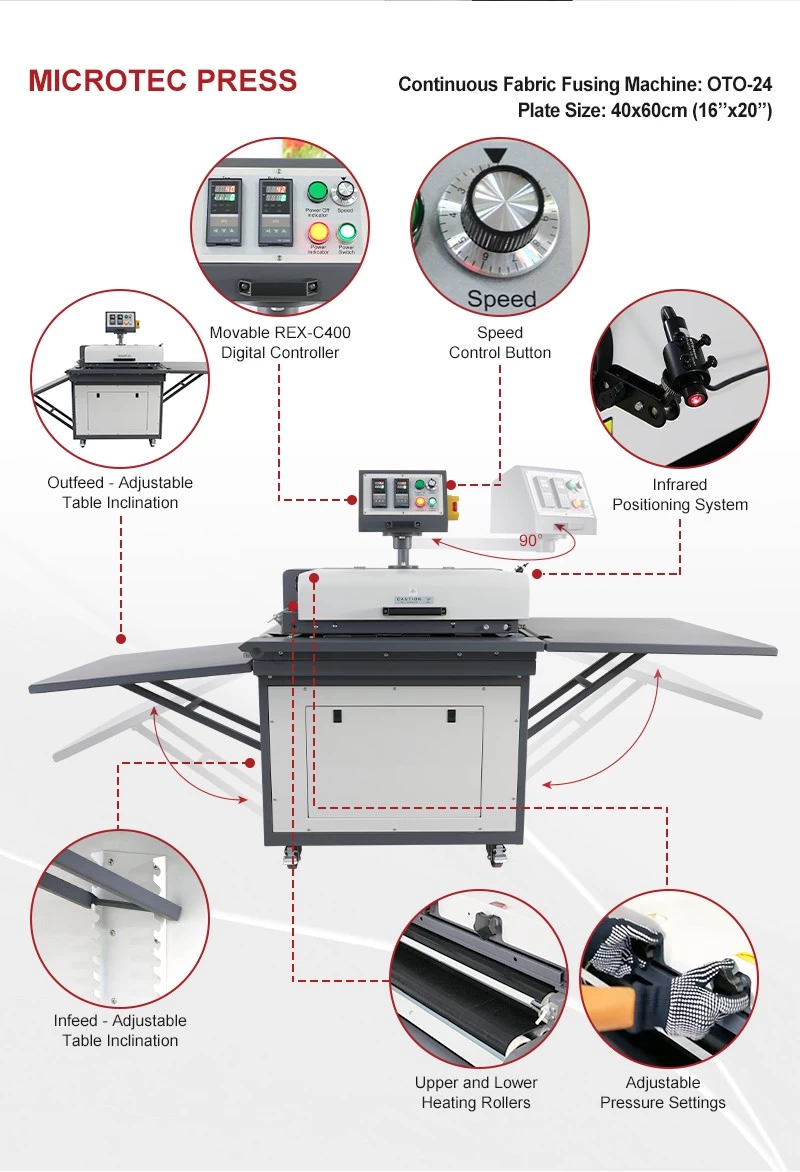

| Model No. | OTO-24 |

| Machine Type | Continuous Fusing, Upper & Lower Heating |

| Controller | Movable REX-C400 Digital Control |

| Power | 7KW |

| Maximum Temp. | 200ºC |

| Temperature Accuracy | ±0.5% |

| Voltage | 220V |

| Current | 32A |

| Frequency | 50/ 60HZ |

| Net Weight | 249KG |

| Gross Weight | 407KG |

| Machine Size | 236x110x140cm |

| Carton Size | 183x119x163cm |

| Certification | CE Approval |

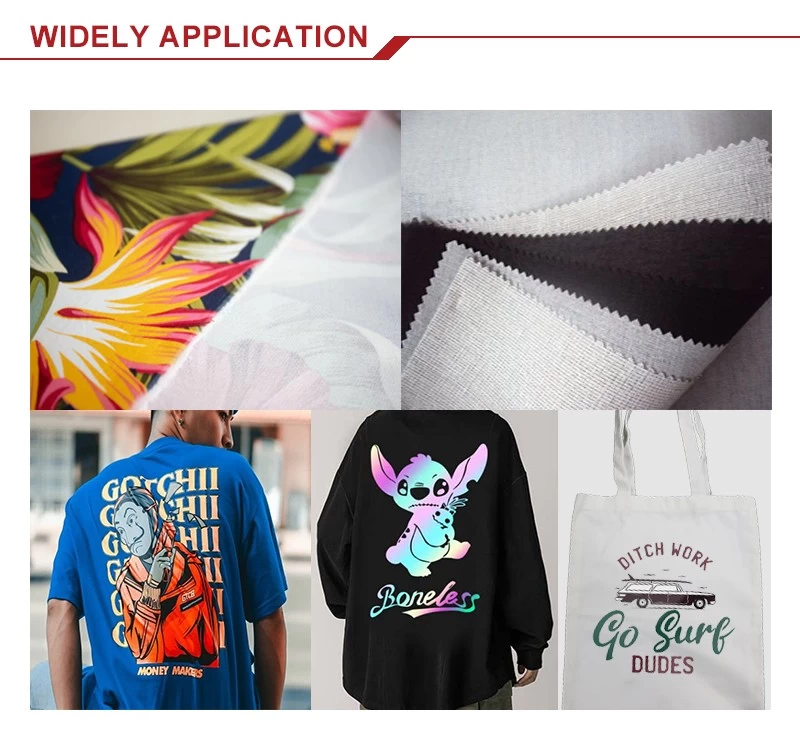

The Continuous Heat Press Machine is not limited to T-shirts; it can also be used for printing on a wide range of apparel items, including hoodies, sweatshirts, and more. Its versatility expands the application possibilities, catering to diverse customer demands.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF