Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

The XSTM-98 Pneumatic Large Heat Press stands out as an exceptional machine tailored for large-scale production. Representing the pinnacle of Microtec's offerings, this heat press boasts a colossal 1.5m x 2.5m (59"x98") heat platen, robust air cylinders, a reciprocating dual tray system, and three operation modes.

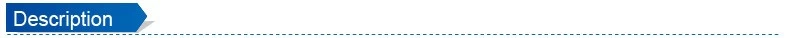

Designed to cater to the needs of large-scale textile, cloth, flag, raincoat, umbrella, metal sheet, and other material sublimation, the XSTM large format heat press introduces innovative features. With dual working tables situated on one side of the machine, the automatic rolling system facilitates seamless printing transitions. After the completion of a print cycle, one table smoothly rolls out, while the other automatically moves into position for the next printing task. This dual tray system not only accelerates production but also significantly reduces labor requirements, allowing a single operator to manage the entire process. The machine offers three production modes: manual, semi-automatic, and fully automatic.

Key Features of XSTM Large Format Heat Press:

Pluggable Heat Elements: The platen incorporates separate heat tubes, enabling easy replacement of individual tubes in case of malfunctions. This design eliminates the need to replace the entire heat platen, resulting in significant cost savings. Learn how to identify and replace heat elements here and here.

How to test the heat platen: https://www.youtube.com/watch?v=GbqDx8NONlA

How to change the heat platen: https://www.youtube.com/watch?v=2G-kFAbYw4g

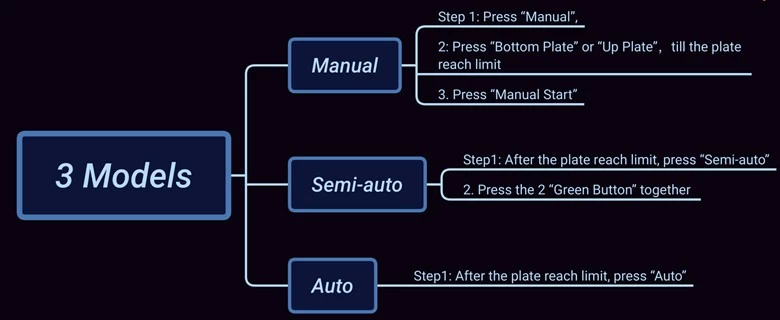

PLC Digital Touch Screen Controller: Equipped with a PLC digital touch screen controller, this heat press allows precise control of each heat tube's temperature. This ensures uniform heat distribution across the entire platen, promoting consistent and high-quality transfers. More information about the PLC controller can be found here.

Dual Working Tables for High Production: With the inclusion of two base plates on a single side, the XSTM-98 facilitates high production volumes, streamlining workflow and maximizing efficiency.

The XSTM-98 Large Heat Press is the epitome of efficiency for your production facility, offering stability and quality that align with your operational needs.

|

|

||||||||||||||||

|

||||||||||||||||

|

|

||||||||||||||||

|

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF