| Comparison of Microtec Rotary Machine |

| Series | MTP | RTR |

| Model | MTP-1700 | RTR-1700 |

| Features | High end,Multifunctional | High end, Most efficient roll to roll rotary heat transfer machine |

| Transfer Width | 1.65m | 1.65m |

| Blankets Width | 1.73m | 1.73m |

| Heating Power | 18KW | 18KW |

| Number of Heating Elements | 12 | 12 |

| Max Temperature | 260℃ | 260℃ |

| Air Pressure | YES | YES |

| Machine Dimension | 1.47x0.98x1.32m | 2.47x1.07x1.45m |

| Working Size | 1.86x1.92x1.0m | |

| Packing Size | 2.6x1.3x1.65m | 2.6x1.3x1.7m |

| Net Weight | 1380kgs | 1380kgs |

| Gross Weight | 1450kgs | 1450kgs |

| Drum Diameter | 420mm | 420mm |

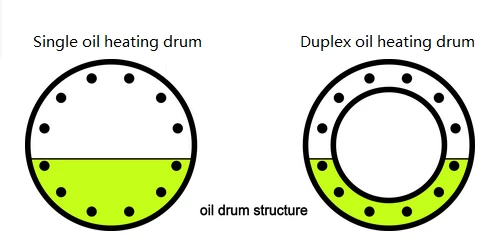

| Heating drum | Duplex oil heating drum | Duplex oil heating drum |

| Printing method | Roll-to-Roll & Cut-Piece | Roll-to-Roll |

| Transfer Speed | Adjustable, up to 3m/min | Adjustable, up to 3m/min |

| Pressure | Adjustable | Adjustable |

| Feeding method | Top | Bottom |

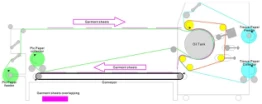

| Collecting method | 3 feeding roller and 2 collecting roller,traditional collecting system | 3 feeding roller and 3 collecting roller, inflatable collecting system,more efficient |

| Working table | With working table | Without working table, for roll to roll only |

| Advantage | *MTP is suitable for thermal & low temperature transferring; *Stable temperature output with duplex oil tank and precise mechanical structure; *Adjustable air pressure control system for perfect transferring; *Roll-to-roll system makes printed materials in parallel without deflection; *Blanket can be separated from oil tank manually when power failure; |

*RTR is designed for transferring flag, wall fabric, curtains, bedding, cushion, umbrella, belt and individual design for printing *Adjustable air pressure control system for perfect transferring; *Roll-to-roll system makes printed materials in parallel without deflection; *Feeding and collecting media by roll-to-roll system with accurate alignment *Precise mechanical structure which results in perfect transferring of different materials |

| Schematic |  |

|