Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

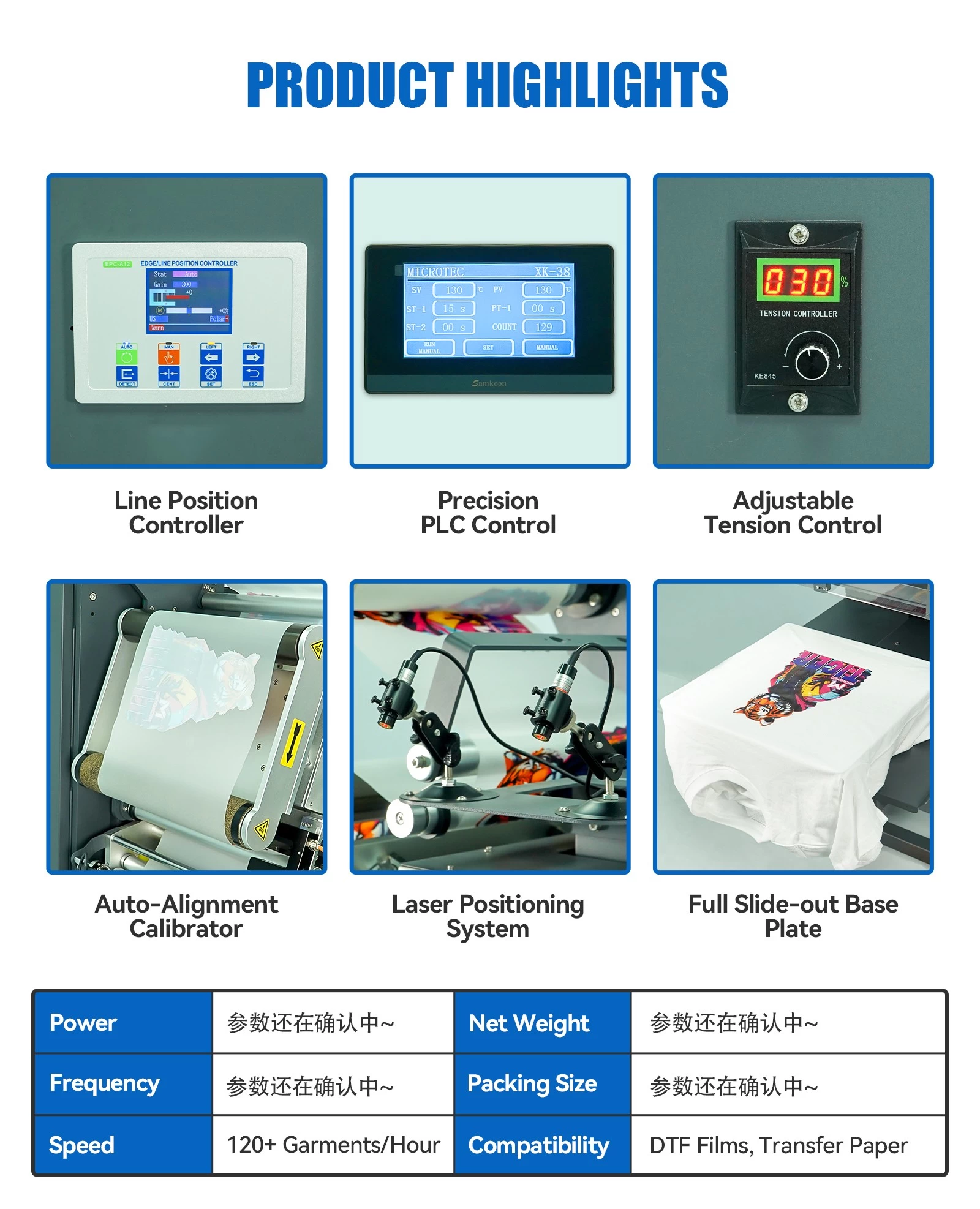

AutoPrint Pro Series - Continuous DTF Heat Transfer Machine

Revolutionizing Apparel Decoration with Fully Automated Precision

The AutoPrint Pro is the world’s first fully automated DTF (Direct-to-Film) heat transfer machine designed for high-volume, uninterrupted production. By integrating automatic film feeding, alignment, peeling, and recovery, it eliminates manual intervention, boosting efficiency by 500% compared to traditional methods. Perfect for custom apparel studios, garment factories, and e-commerce fulfillment centers, this machine delivers flawless transfers on fabrics ranging from thin T-shirts to thick hoodies, with zero setup time between jobs.

Why AutoPrint Pro?

Traditional DTF transfers demand constant human intervention—aligning films, adjusting temperatures, and peeling waste—tasks that drain time and resources. The AutoPrint Pro revolutionizes this process with end-to-end automation. Simply load the garment, press start, and watch the machine handle the rest: auto-feeding film, AI-powered alignment, instant peeling, and waste recovery—all without a single manual adjustment.

1. End-to-End Automation

Auto-loading DTF film, real-time alignment, and instant peeling/recovery.

Hands-free operation: Just load garments and press start.

2. Smart Precision

Dual infrared sensors + auto-correction for perfect alignment.

Adjustable tension control with real-time monitoring.

3. Unmatched Flexibility

Transfer sizes: 15x15cm to 38x38cm (swapable heating plates in seconds).

Compatible with curved surfaces (hoodies, sleeves) via extendable baseplate.

4. Precise Alignment

Dual infrared sensors automatically align the DTF film for perfect positioning, ensuring flawless transfers.

5. Safety Features

Equipped with an emergency stop switch and casters for easy mobility, ensuring smooth operation.

| Model. | XK-38 | ||

| Types of machines | Auto, Rotary, Continuous | ||

| Controller | PLC Controller | ||

| Printable Articles | Up to 10mm Thickness (Only for DTF Film) | ||

| An air compressor is required | Yes | ||

| Voltage | 110V/220V | ||

| Speed | 120~130 pieces of T-shirt/hour | ||

| Power | 1.8KW | ||

| Packaging size (cm) | 114x101x200cm | ||

Who Needs This Machine?

Garment Factories: Replace manual labor with 1,200+ daily prints per machine.

Custom Print Shops: Offer “1-piece orders” without sacrificing profit margins.

Sportswear Brands: Perfectly print on T-shirts, bag, and hoodies

Your Next Step to Automation

The AutoPrint Pro isn’t just a machine—it’s your competitive edge. Free remote training, and technical support, it’s the safest investment for scaling your business.

Why Settle for Manual When Automation Awaits?

Transform your production line with the AutoPrint Pro—where speed meets precision, and every second counts.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF