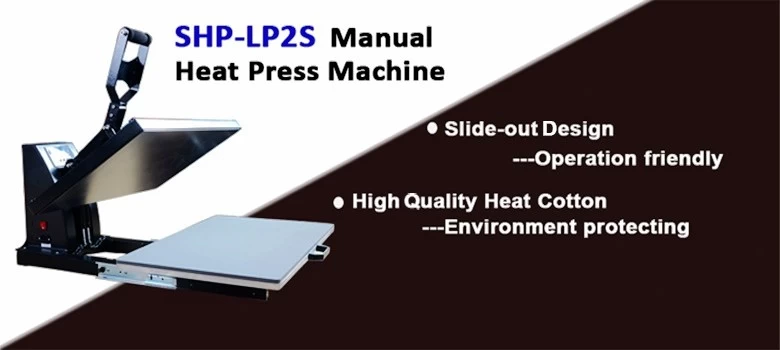

The P2 Manual Heat Press machine with Draw-out Under Platen is a part of the SHP series, designed to offer an economical solution for heat transfer applications. This clamshell heat press boasts user-friendly features and enhanced functionality to meet the diverse needs of users.

Users can opt for a slide-out bed design, adding convenience to the sublimation transfer process. The slide-out feature streamlines the workflow and simplifies the placement and removal of items during heat transfer. Meantime SHP series offers flexibility with the option to choose between manual or auto-open configurations. This adaptability allows users to select the mode that best suits their specific requirements.

SHP Manual Heat Press machine stands out for its economic design, user-friendly features, and enhanced safety measures. Whether opting for manual or auto-open configurations, users can enjoy the flexibility and reliability needed for efficient heat transfer processes across a range of applications.

Ergonomic Handle: The clamshell design incorporates an ergonomic handle, facilitating low-pressure release and effortless opening and closing of the heat press. This feature adds to the overall user convenience during operation.

GY-04 Digital Controller: Equipped with a GY-04 digital controller, this manual heat press machine ensures simple and efficient operation. The LED display enhances visibility, making it suitable for operation in low-light working environments.

Manual or Auto Open Options: The SHP series offers flexibility with the option to choose between manual or auto-open configurations. This adaptability allows users to select the mode that best suits their specific requirements.

Slide-Out Bed: Users can opt for a slide-out bed design, adding convenience to the transfer process. The slide-out feature streamlines the workflow and simplifies the placement and removal of items during heat transfer.

Upgraded Heating Plate and Element: The heat press machine incorporates upgraded heating plates and elements to prevent uneven heat distribution and potential failures. This ensures consistent and reliable performance, resulting in high-quality heat transfers.

| Model No. |

SHP-15LP2S/ SHP-20LP2S/ SHP-24LP2S |

| Machine Type |

Manual, Clamshell, Slide-out Plate |

| Platen Size |

15"x15"/16"x20"/16"x24" (38x38cm/40x50cm/40x60cm) |

| Under Plate |

Draw-out |

| Controller |

GY-04 Digital Time & Temp. Control |

| Printable Articles |

Thin Materials |

| Opening Angle |

50 Degrees |

| Gas Spring Control |

Yes |

| Voltage |

120V/ 220V |

| Power |

15: 1.5KW/ 1.8KW; 20/24: 1.6KW/ 1.8KW |

| Time Range |

0-999 Sec. |

| Maximum Temp. |

225 C |

| Temperature Accuracy |

±0.5% |

| Packing Size |

77x47x51cm/ 81x61x53cm/ 78x72x53cm |

| Gross Weight |

38kg/ 49kg/ 55kg |

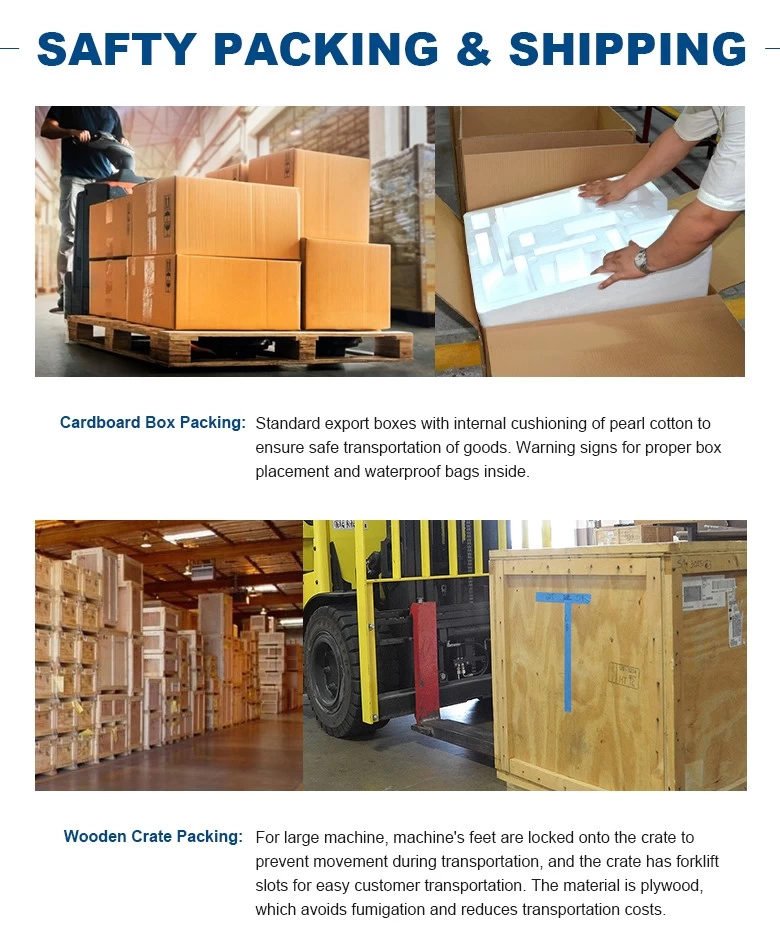

All the machines are packed in carton with full wrapped styrofoam and there are manual instructure offered for each set of machine.