Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

Overview: Introducing the SSE Robotic Automated Peeling & Unloading Machine, a cutting-edge, fully automated solution designed to streamline your thermal transfer printing processes.

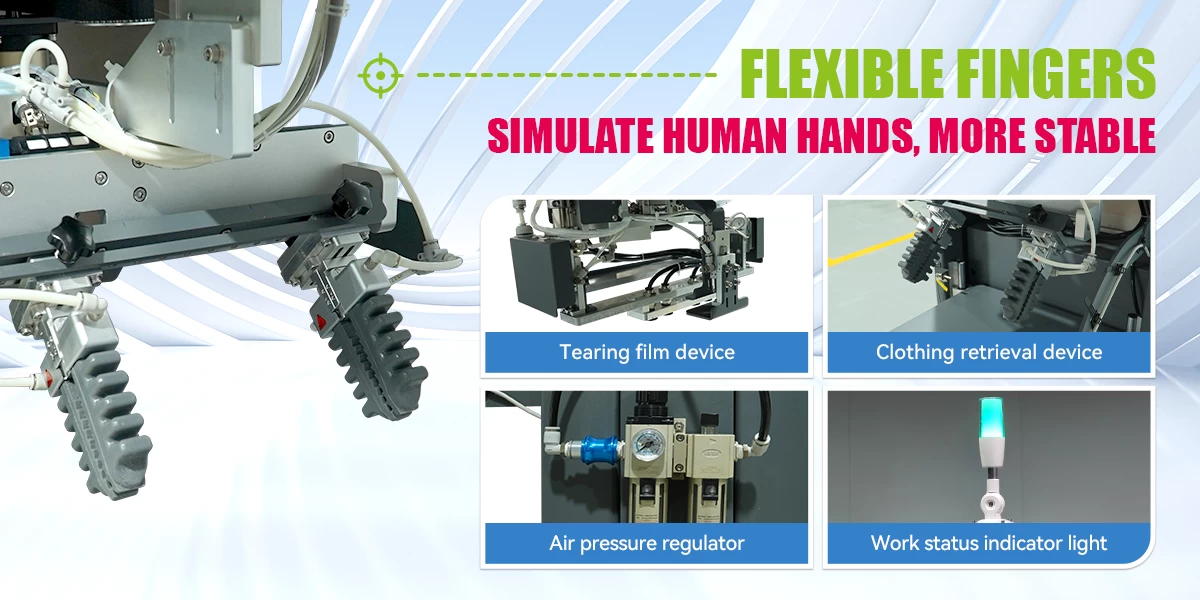

Perfectly complementing the automated feeding system, this hi-tech robotic machine effortlessly extracts DTF films from completed heat transfers, tears them off, and places the transferred items into a collection basket. Boost your productivity and reduce manual labor with this high-performance machine, engineered to meet the growing demands of the printing industry.

Fully Automatic Operation: Say goodbye to manual peeling and unloading with this fully automated robotic system. The SSE-002 handles the entire process from tearing off DTF films to placing the finished products into a storage basket, reducing downtime and significantly enhancing operational efficiency.

High Capacity: With a capacity of ≥180 pcs/hour, this machine offers exceptional throughput, making it ideal for large-scale operations where high-volume production is essential.

Seamless Integration: Designed to work in perfect harmony with other thermal transfer printing machines, this robotic peeling and unloading system ensures a smooth and continuous production workflow. Say goodbye to bottlenecks and hello to increased productivity.

User-Friendly Control Panel: The PLC-controlled system features an easy-to-use TK871IP touch screen for effortless operation and real-time monitoring. Simplify your workflow with intuitive controls that make adjustments a breeze.

Customizable for Various Needs: Whether you're working with different DTF film specifications or production quantities, this machine can be tailored to fit your specific business requirements, optimizing your processes for maximum efficiency.

Energy-Efficient & Durable: With a power consumption of 1200W and a reliable air source of 0.4MP-0.6MP, this machine operates efficiently, saving both energy and operational costs while ensuring a long service life.

Compact and Robust Design: Despite its impressive capabilities, the SSE-002 features a compact size of 120x80x178 cm and weighs just 205 kg, making it suitable for various workspaces without compromising on performance.

Model No.: SSE-002

Machine Type: Hi-tech Robotic, Fully Automatic

Control Panel: PLC

Operation Interface: TK871IP Touch Screen

Capacity: ≥180 pcs/hour

Voltage: 220V

Power: 1200W

Air Source: 0.4MP-0.6MP

Machine Size: 120x80x178 cm

Net Weight: 205 kg

Conclusion: The SSE Robotic Automated Peeling & Unloading Machine is the ultimate solution for businesses looking to enhance their productivity and automate their thermal transfer printing processes.

This state-of-the-art machine helps you reduce manual labor, increase efficiency, and meet high-volume production demands while ensuring a smooth and cost-effective workflow.

Upgrade your operations today and stay ahead in the competitive sublimation and DTF printing industry!

Reduced Manual Labor: Save time and reduce the need for manual intervention, freeing up your team to focus on other important tasks.

Improved Efficiency: The automated system speeds up the peeling and unloading process, ensuring a faster turnaround time and higher production rates.

Cost-Effective & Sustainable: With energy-saving features and durable components, the SSE-002 provides long-term value and contributes to cost savings.

Perfect for Sublimation and DTF Printing: Whether you're working with T-shirts, hoodies, or other thermal transfer items, this machine is engineered for seamless integration into your sublimation printing or DTF process.

At Microtec, our primary goal is to ensure that our customers can carry out heat transfer activities seamlessly. To support this, we offer FREE SPARE PARTS with qualifying orders, alongside the following comprehensive guarantees:

We are dedicated to providing long-term reliability and peace of mind for your heat transfer operations.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF