Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

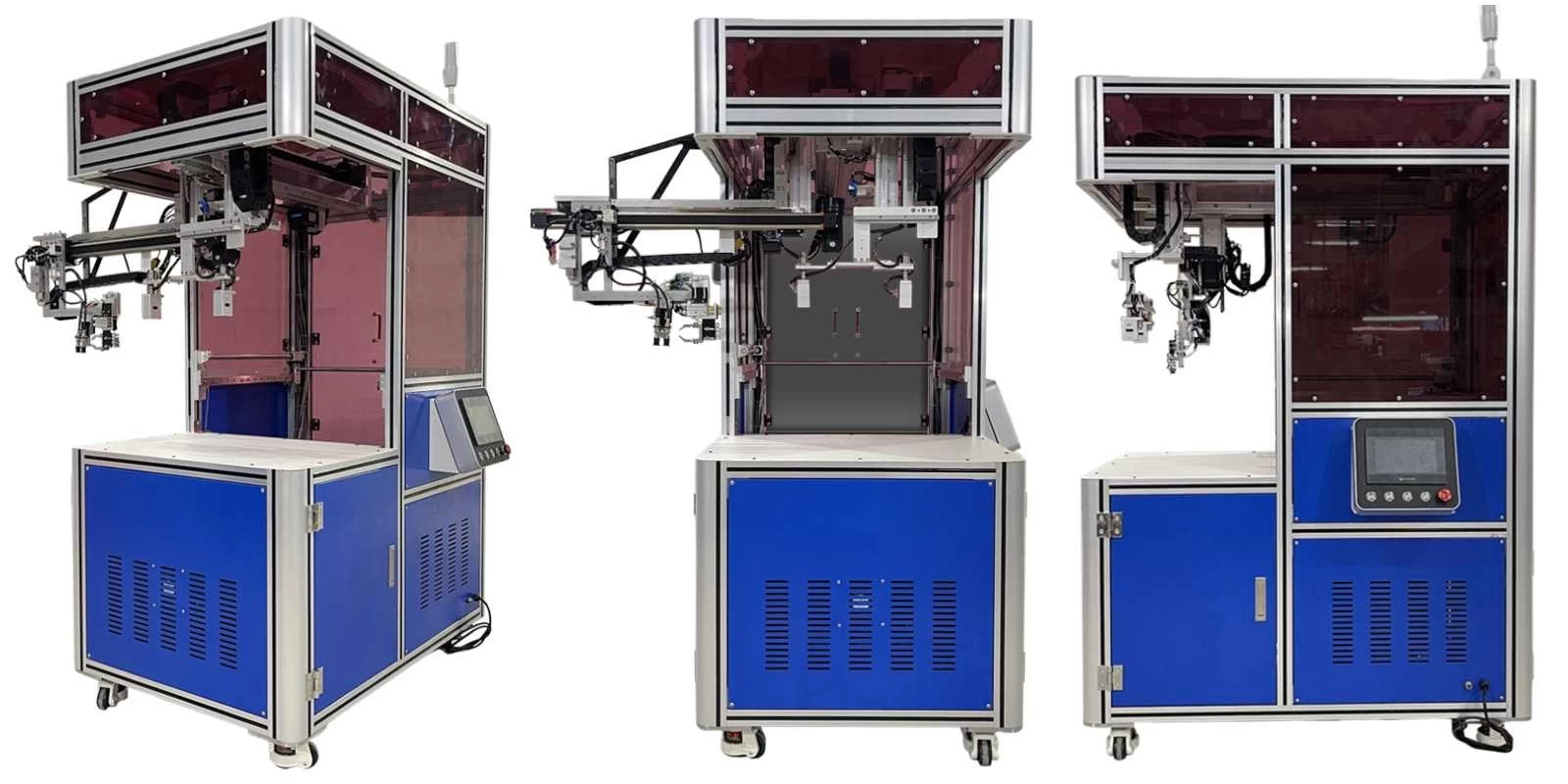

Microtec Robotic Automated Peeling & Unloading Machine designed to complement our automated feeding system. This innovative device seamlessly extracts DTF films from completed heat transfers, automatically tears them off, and efficiently places the transferred items into a collection basket. This process not only saves valuable time but also significantly reduces the need for manual intervention. Say goodbye to unnecessary downtime and experience a significant boost in productivity, allowing your business to meet growing demands and stay ahead in the market.

Integrated with Microtec 4 Station Automatic Rotating Heat Press Machine, only one worker can transfer hunderds T-shirts or hoodies etc in one hour, providing unparalleled convenience and high efficiency for sublimation printing businesses.

Complete Automation:

This machine offers end-to-end automation in the unloading process, from tearing off DTF films to separating and placing the transferred items into the storage basket. This reduces manual labor and enhances overall process efficiency.

Seamless Integration:

With its ability to seamlessly interface with heat transfer machines, our Automatic Unloading Machine ensures a continuous production flow, eliminating bottlenecks and maximizing productivity.

Customizable for Varied Needs:

The machine's adaptability to different DTF film specifications and production quantities allows businesses to tailor their processes, optimizing production according to specific requirements.

Energy-Efficient and Durable:

Not only does it save energy with its efficient operation, but the machine also boasts a long service life, contributing to sustainability and cost-effectiveness over the long term.

Ideal for Thermal Transfer Printing:

Tailored to the specific needs of the thermal transfer printing industry, our Robotic Material Loading System represents an ideal choice for businesses seeking streamlined processes, reduced errors, and enhanced overall productivity.

| Model No. | SSB-003 |

| Machine Type | Hi-tech Robotic, Full Automatic |

| Controller | PLC Touch Screen Panel |

| Operation Interface | K871IP Touch Screen |

| Voltage | 220V, Single-phase |

| Power | 1200W |

| Air Source | 0.4MP-0.6MP |

| Machine Size | 120x80x178cm |

| Net Weight | 205kg |

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF