Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

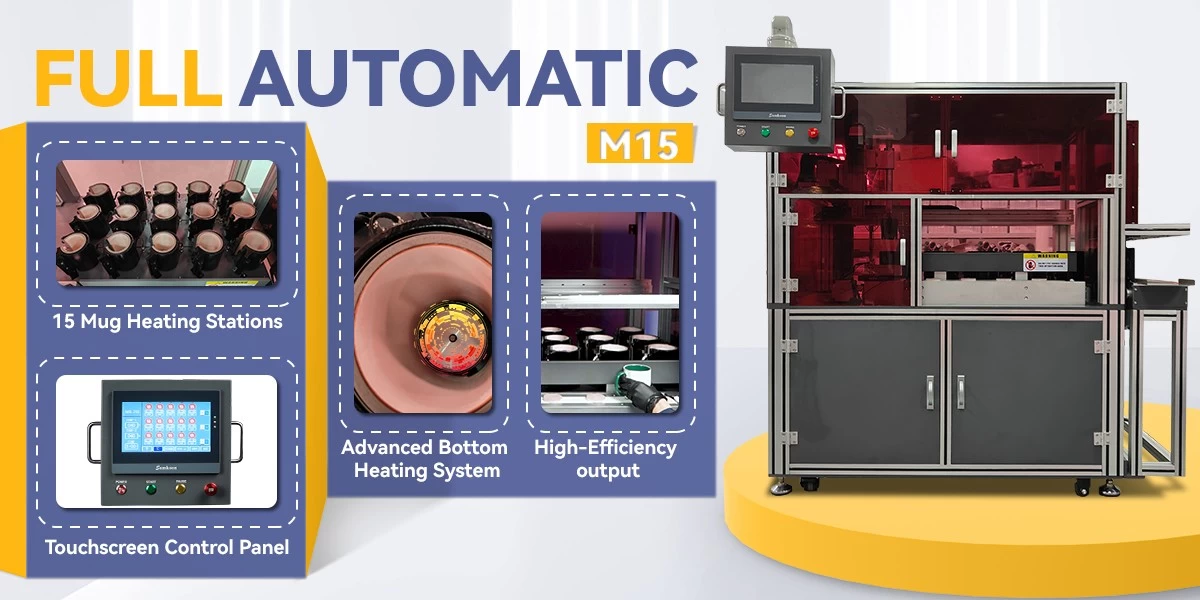

Our 15-Station Robotic Auto Mug Heat Press revolutionizes the heat transfer industry with its fully automated workflow, tailored for the fast-paced demands of the print-on-demand (POD) market.

Powered by advanced robotics and intelligent control systems, this machine seamlessly handles mug feeding, positioning, heating, pressing, and cooling—all without manual intervention. With flexible batch modes (5/10/15 mugs per cycle), it maximizes productivity while slashing labor costs, making it ideal for both small custom orders and high-volume production.

End-to-End Automation

Robotic Mug Gripper: Precision handling ensures zero damage and consistent results.

Mug Feeding & Discharge Conveyors: Automated loading/unloading reduces labor dependency.

Mug Positioning Sensor: Millimeter-level accuracy eliminates misalignment.

Advanced Heating Technology

Independent Heating Stations: Customizable temperature control per mug for diverse materials.

Bottom Heating Assembly: Ensures 360° uniform heat distribution for vibrant, long-lasting prints.

Smart Control & Safety

PLC Control Panel: Intuitive touchscreen interface with preset modes for quick setup.

Gripper Pressure Regulating Valve & Filter: Adjustable pressure for varied mug shapes.

Emergency Stop System: Instant shutdown for operational safety.

Scalability & Flexibility

5/10/15-Station Modes: Dynamically adjust capacity to match order demands.

Movable Casters: Easy relocation for multi-environment setups.

Rapid Cooling System: Reduces cycle time for faster turnaround.

Why Choose Our Machine?

Unmatched Cost Efficiency

Replaces 3-5 manual workers, reducing per-mug costs by over 40%.

24/7 operation boosts output by 300%, accelerating ROI.

Premium Quality & Reliability

Industrial-grade PLC system ensures 99.9% defect-free rate.

Independent temperature/pressure control handles complex designs and gradients flawlessly.

Future-Proof POD Solution

Smart Production Line Integration: Seamlessly connect with Microtec’s High-Speed Automatic Mug Wrapping Machine and KP-650 Precision Paper Cutter to build an end-to-end automated production line—from pattern cutting and precise wrapping to high-efficiency heat transfer—dramatically reducing manual handling.

Technical Specifications

Power: 6KW

Voltage: 220V/380V

Frequency: 50-60HZ

Mug Transfer Options: 5pcs/10pcs/15pcs

Machine Size: 170*110*180cm

Net Weight: 516kg

Contact Us for a free demo and customized production solutions!

Let Automation Drive Your Competitive Edge!

Microtec's Commitment to Customer Support

At Microtec, our primary goal is to ensure that our customers can carry out heat transfer activities seamlessly. To support this, we offer FREE SPARE PARTS with qualifying orders, alongside the following comprehensive guarantees:

Lifetime Technical Support for all heat press machines.

Two-Year Warranty on the machine.

Five-Year Warranty on fusions and welds.

Five-Year Warranty on the heating plate.

Six-Month Warranty on heaters for cups, plates, and caps.

We are dedicated to providing long-term reliability and peace of mind for your heat transfer operatio

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF