Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

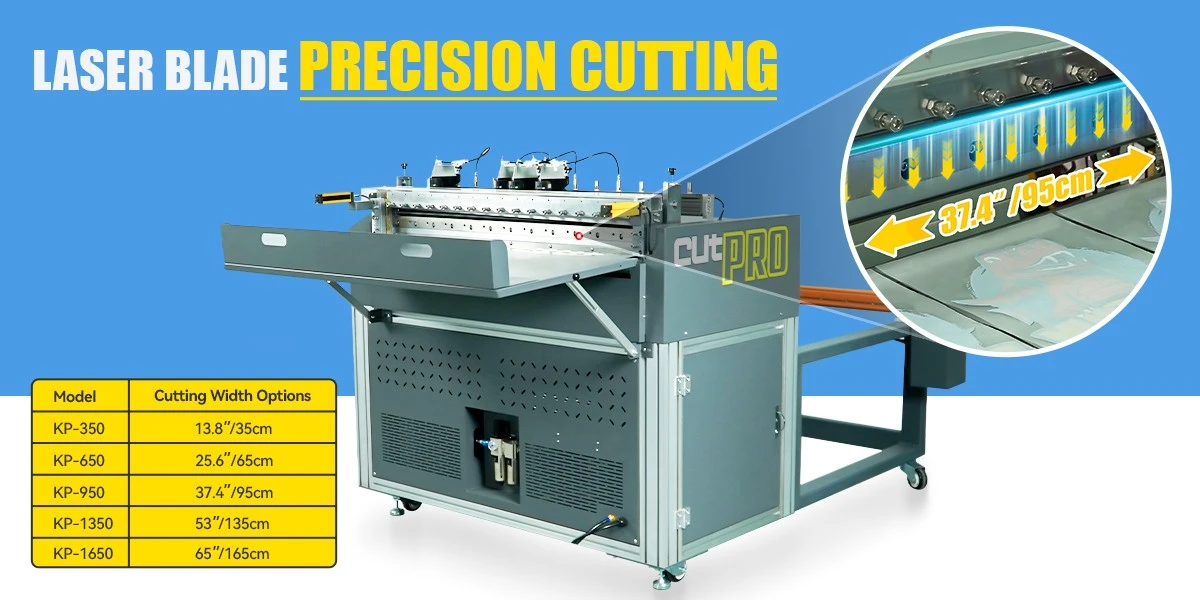

The KP‑950 DTF Film Slitting Machine is a professional solution designed for efficient, high-precision cutting of medium-format DTF film rolls up to 90cm wide. It effortlessly handles a wide range of roll materials including PVC, PET, and various films. Move beyond slow, error-prone manual cutting and embrace end-to-end automation that maximizes your output and profitability. continuous production while saving time and reducing material waste.

End-to-End Automation: Load your roll material and let the machine do the rest. From auto-feeding to precision cutting and stacking, the KP-950 operates with minimal operator intervention, significantly reducing labor costs.

Pixel-Perfect, PLC-Controlled Cuts: Experience flawless accuracy with every cut. The advanced Programmable Logic Controller (PLC) ensures every piece is identical, eliminating material waste and ensuring consistent, high-quality results for your customers.

Wrinkle-Free, Auto-Sensing Platform: Our proprietary auto-sensing technology guarantees perfect material alignment before every cut. This creates a wrinkle-free processing environment, crucial for producing perfect DTF transfers and other sensitive materials.

Built for Safety & Versatility: Operator safety is paramount. The KP-950 is equipped with an emergency stop function and a protective safety light curtain. The adjustable cutting distance allows you to easily customize the machine for different jobs and material types.

| Model Options | KP-350 / KP-650 / KP-950 / KP-1350 / KP-1650 |

|---|---|

| Controller | PLC Touch Control |

| Max Cutting Width | 35cm / 65cm / 95cm / 135cm / 165cm |

| Cutting Thickness | 0 – 2mm |

| Blade Type | Pneumatic Cutter (76mm blade) |

| Cutting Speed | 0.5– 2 m/s (Customizable) |

| Cutting Modes | Auto & Manual |

| Voltage | 220V |

| Power Consumption | 400W |

| Air Compressor | Required (not included) |

| Safety System | CE-certified with emergency stop & auto shutoff |

| Material Compatibility | PET, DTF film, PVC, paper rolls |

DTF / DTG print shops

Custom apparel & merchandise producers

Signage and sticker manufacturers

Packaging and labeling industries

Textile and promotional goods suppliers

At Microtec, our primary goal is to ensure that our customers can carry out heat transfer activities seamlessly. To support this, we offer FREE SPARE PARTS with qualifying orders, alongside the following comprehensive guarantees:

We are dedicated to providing long-term reliability and peace of mind for your heat transfer operations.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF