In a dynamic era of technological innovation, the decorated apparel market continues to witness significant growth. According to the latest report by Grand View Research, Inc., the global decorated apparel market size was valued at USD 28.98 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 13.0% from 2024 to 2030. As the demand for personalized and customized clothing escalates, businesses are seeking innovative solutions to streamline production processes and enhance efficiency.

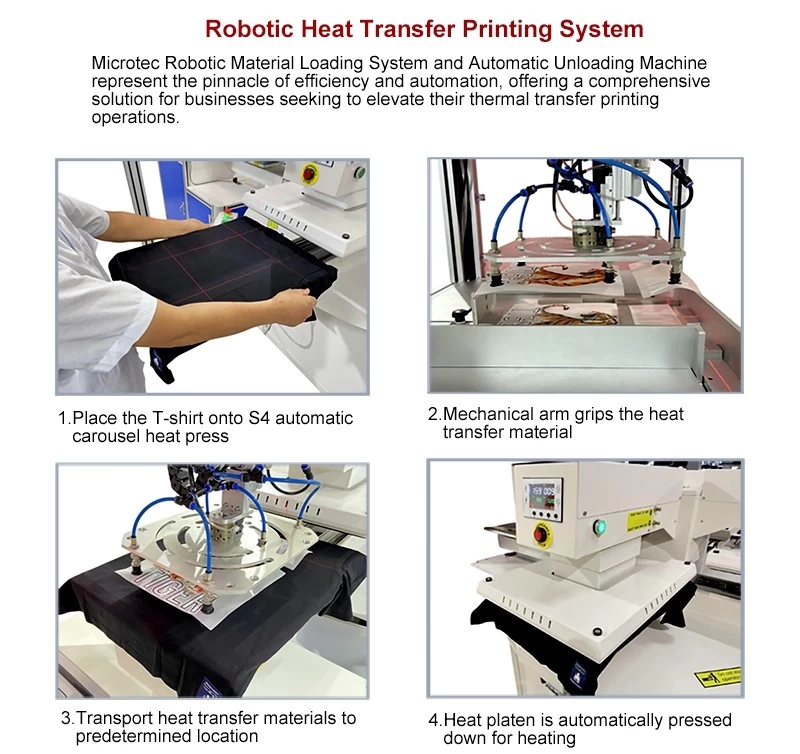

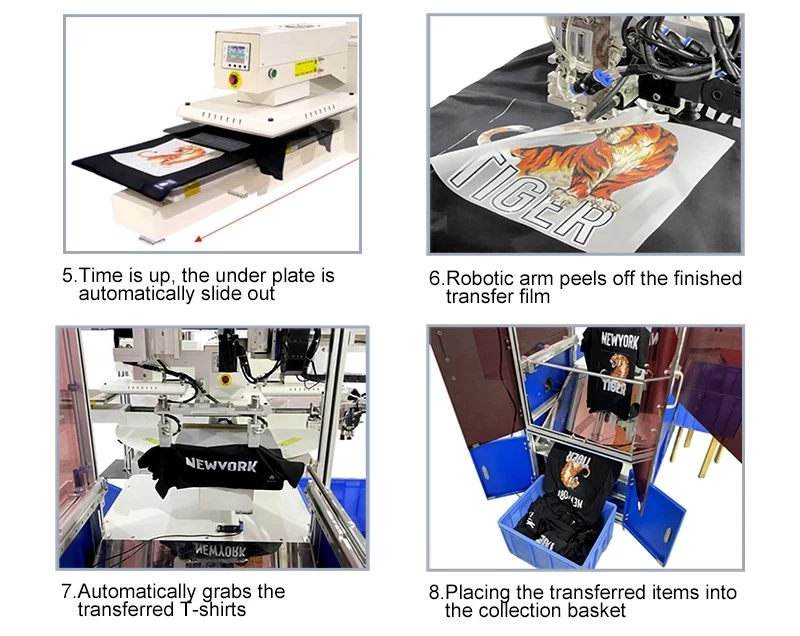

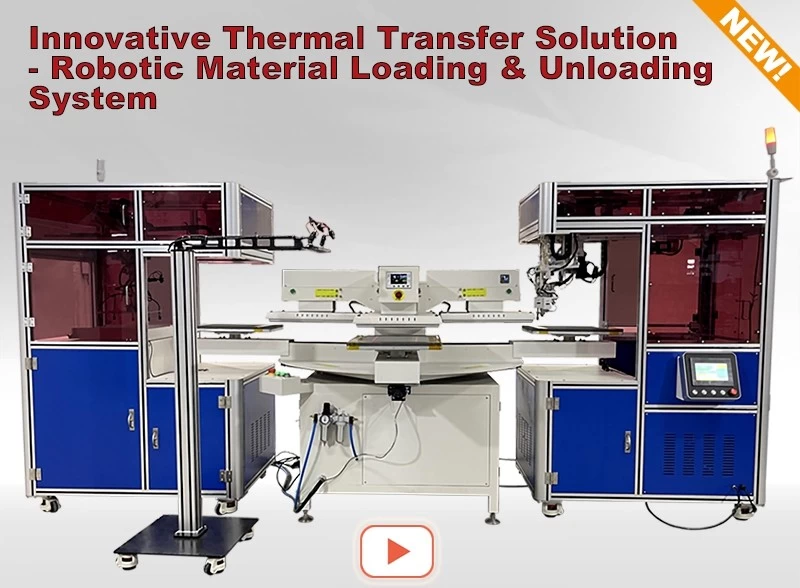

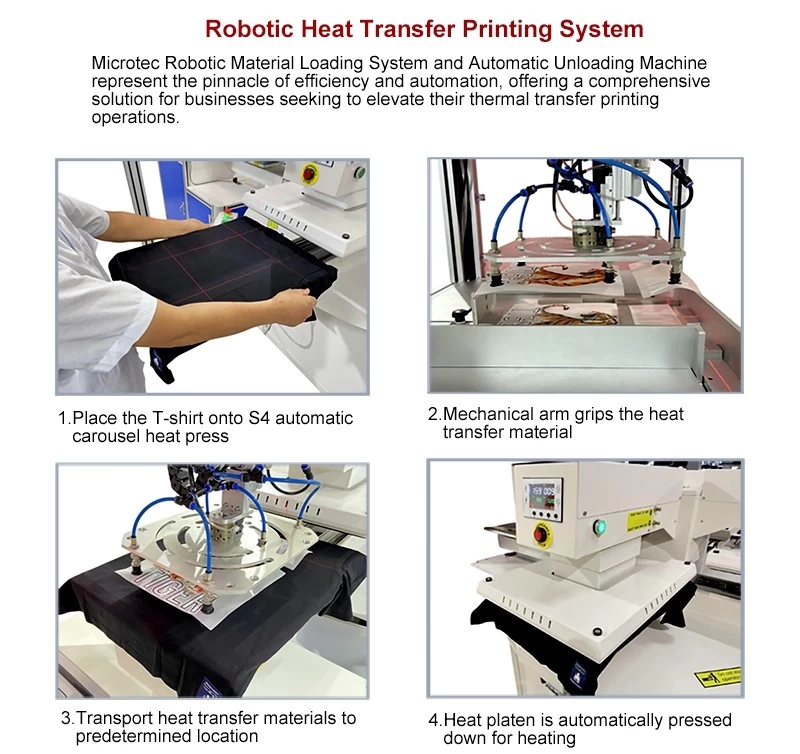

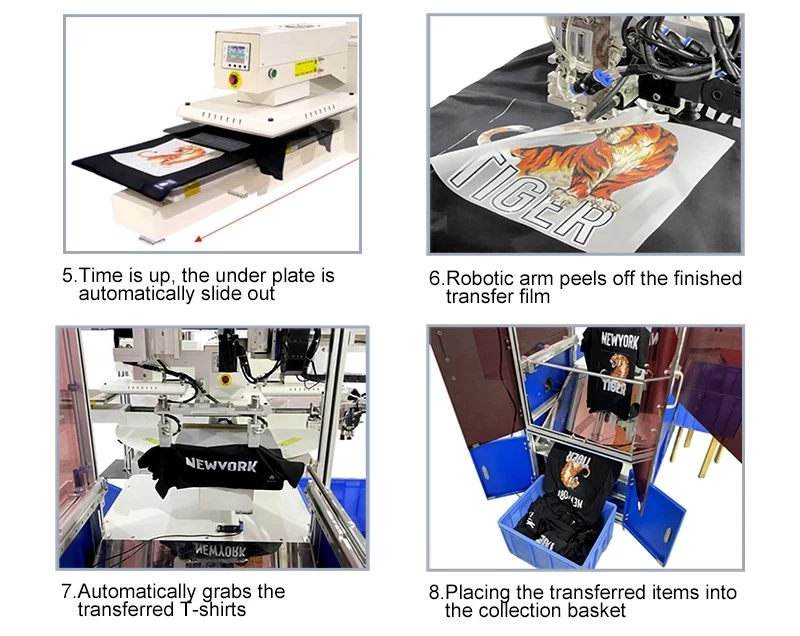

In response to this burgeoning market demand, Microtec is proud to introduce its latest breakthrough: the Automated Material Handling Solution. This state-of-the-art system combines the Robotic Material Loading System and the Automatic Unloading Machine, offering unparalleled efficiency and automation in the production of decorated apparel.

Advantages for the Decorated Apparel Market:

1. Enhanced Efficiency:

- The Microtec Automated Material Handling Solution optimizes the loading and unloading processes, significantly reducing manual labor and production time. With seamless integration into existing production workflows, businesses can achieve higher throughput and meet growing customer demands efficiently.

2. Improved Quality:

- By minimizing human error and ensuring precise material handling, Microtec's solution contributes to enhanced product quality and consistency. The robotic precision of the loading system and the automated unloading process result in superior finished products, satisfying even the most discerning customers in the decorated apparel marke

3. Increased Customization:

- With the ability to adapt to various specifications and production quantities, the Automated Material Handling Solution empowers businesses to offer a wider range of customization options to their customers. From intricate designs to large-scale production runs, Microtec's solution delivers flexibility without compromising efficiency.

4. Cost Savings:

- The automation provided by Microtec's solution reduces the reliance on manual labor, minimizing labor costs and optimizing resource utilization. Additionally, the energy-efficient design and long service life of the system contribute to overall cost savings for businesses operating in the decorated apparel market.

5. Sustainability Focus:

- Microtec is committed to sustainability, and the Automated Material Handling Solution reflects this ethos. By reducing material wastage, energy consumption, and environmental impact, businesses can align with sustainability goals while maintaining high productivity levels.

About Microtec:

Microtec is a leading provider of innovative solutions for the decorated apparel industry, dedicated to revolutionizing production processes and enhancing efficiency. With a focus on automation, precision, and sustainability, Microtec continues to drive forward-thinking advancements that empower businesses to thrive in a competitive market landscape.

For inquiries or demonstrations of Microtec's Automated Material Handling Solution, please contact: sales@szmicrotec.com

As the decorated apparel market continues to expand, Microtec's Automated Material Handling Solution stands poised to revolutionize production processes, driving efficiency, quality, and sustainability for businesses worldwide.

Sources:

- Grand View Research, Inc. "Decorated Apparel Market Size, Share & Trends Analysis Report By Product (T-shirts, Shirts), By Distribution Channel (Offline, Online), By Region, And Segment Forecasts, 2021 - 2028." Link