Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

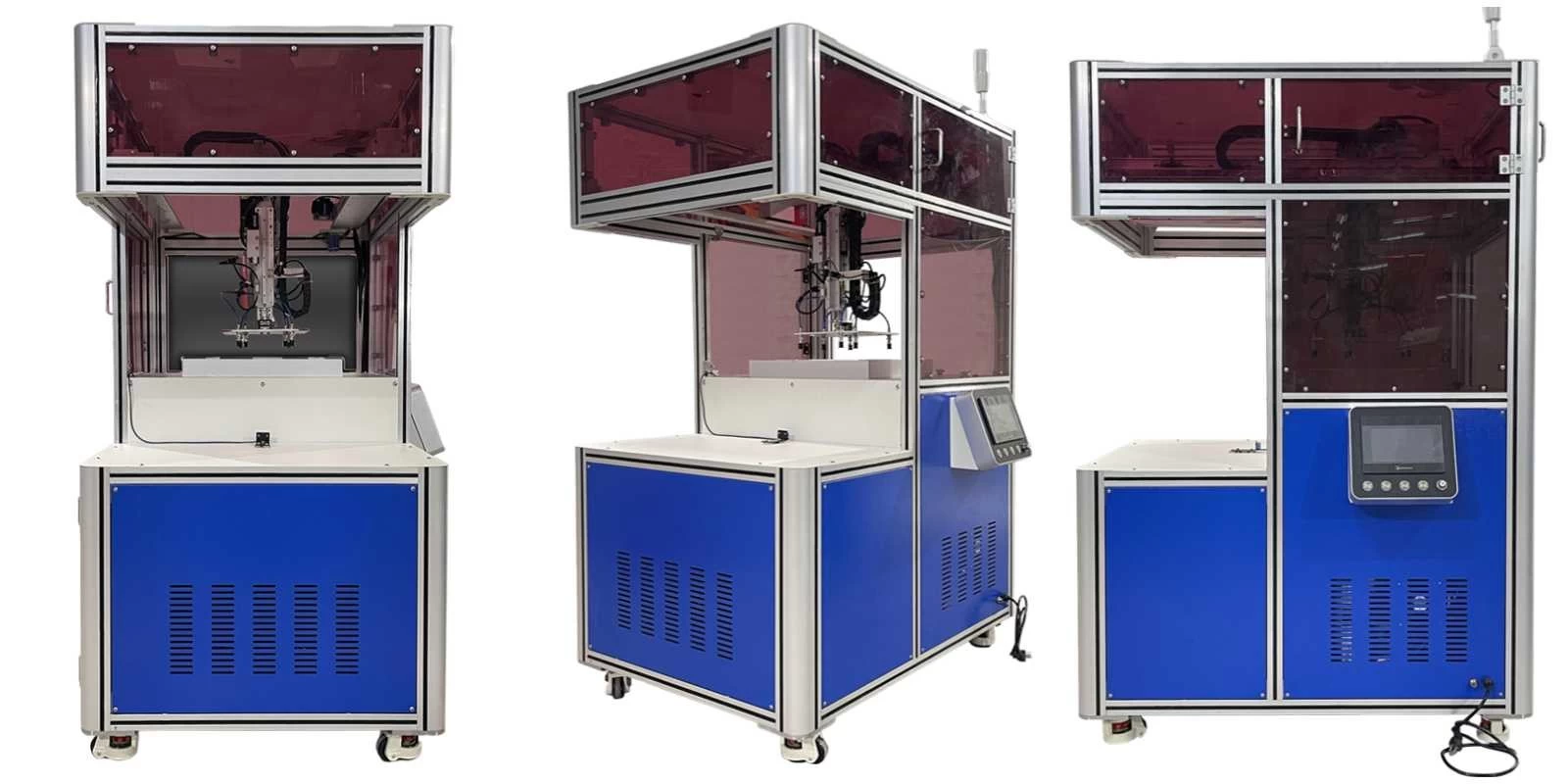

Microtec Robotic Fully Automated Feeding Machine represents a significant advancement in heat transfer technology. It employs a mechanical arm resembling a robotic hand to securely grip and transport heat transfer materials to predetermined locations. The suction cup effortlessly releases the material, allowing the arm to return to its initial position. This intelligent and efficient equipment boasts unparalleled features, enabling non-stop printing for extended periods. Say goodbye to unnecessary downtime and experience a significant boost in productivity, allowing your business to meet growing demands and stay ahead in the market.

Integrated with Microtec 4 Station Automatic Rotating Heat Press, only one worker can transfer hunderds T-shirts or hoodies etc in one hour, providing unparalleled convenience and high efficiency for sublimation printing businesses.

Smart Automation:

Our fully automated feeding machine operates with advanced intelligence, streamlining the material handling process for optimal efficiency.

Accurate Material Placement:

The system precisely positions DTF film or heat transfer paper on a four-station heat transfer machine, eliminating manual errors and reducing material wastage.

Fast, Stable, and Accurate Operation:

The Robotic System ensures swift, stable, and accurate material handling. Seamlessly integrating with thermal transfer machines, it enables continuous production, significantly improving efficiency and product quality.

Adaptable to Varied Production Needs:

This system can be easily adjusted to accommodate different specifications and quantities of DTF film or thermal transfer paper, making it versatile for various production scenarios.

User-Friendly and Low Maintenance:

Simple operation and easy maintenance characterize our system. It requires minimal energy consumption and boasts a long service life, making it a reliable and sustainable choice for businesses.

Ideal for Thermal Transfer Printing:

Tailored to the specific needs of the thermal transfer printing industry, our Robotic Material Loading System represents an ideal choice for businesses seeking streamlined processes, reduced errors, and enhanced overall productivity.

| Model No. | SSB-002 |

| Machine Type | Hi-tech Robotic, Full Automatic |

| Controller | PLC Touch Screen Panel |

| Feeding Material Size | ≤30x30cm |

| Operation Interface | K871IP Touch Screen |

| Voltage | 220V, Single-phase |

| Power | 900W |

| Air Source | 0.4MP-0.6MP |

| Machine Size | 120x90x178cm |

| Net Weight | 245kg |

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF