Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

Introducing the new Auto Heat Press - MAX CLAM Auto Open Heat Press with Detachable Control Box! Building upon the existing features of the renowned MAX CLAM Heat Press, our latest innovation incorporates a game-changing element - a detachable control box. This detachable control box offers unparalleled convenience and efficiency, making it a perfect solution for post-sales maintenance.

The unique selling point of this new machine lies in its easily removable control box. When customers encounter any operational issues with the equipment, they can effortlessly detach the control box and send it back to the supplier for diagnostics. This process significantly reduces manual intervention, ensuring faster and more accurate problem identification. As a result, downtime is minimized, and any necessary repairs can be carried out promptly, maximizing productivity for our valued customers.

Enhanced After-Sales Support: The detachable control box simplifies troubleshooting and minimizes downtime. Clients can send the control box for assessment, enabling swift and targeted repairs, thus optimizing machine performance.

Streamlined Maintenance: With the detachable control box, maintenance becomes a breeze. It eliminates the need for on-site inspection and reduces the potential for human errors during servicing.

Seamless Integration: The detachable control box seamlessly integrates with the machine's existing design, ensuring a user-friendly experience for both new and existing customers.

Durability and Safety: The control box is built with durability and safety in mind, meeting the highest industry standards for reliability and performance.

Intuitive Interface: The user-friendly interface of the control box allows for easy operation, calibration, and adjustment of various settings, ensuring precise and consistent results.

|

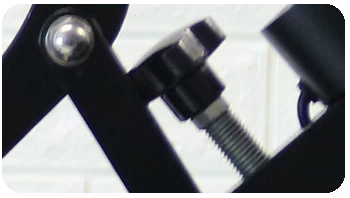

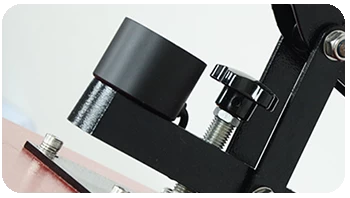

Pressure Adjust Knob: To adjust the pressure easily when sublimate items with different thicknesses. |

|

Auto-Open Release: This auto open heat press utilizes an electromagnet release mechanism with a gas spring. |

|

|

Detachable Control Box: This design simplifies troubleshooting and minimizes downtime, enabling swift and targeted repairs. |

|

|

Double Gas Springs: The upgraded double gas springs to ensure more |

|

|

Anti-Scald Protect Cover: Metal cover above the heat platen. It can protect user from scalding. |

With the Auto Heat Press - MAX CLAM Auto Open Heat Press with Detachable Control Box, we are revolutionizing the heat press industry by combining cutting-edge technology with customer-centric design. Our commitment to providing exceptional after-sales support and hassle-free maintenance sets this machine apart from the competition, making it the ideal choice for businesses seeking reliable, efficient, and innovative heat press solutions.

Upgrade your heat press experience today with our game-changing Auto Heat Press - the ultimate solution for your heat transfer needs!

| Model No. | TC-15/ TC-20 |

| Machine Type | Auto Release, Plug-in Electric Box |

| Platen Size | 15"x15"/ 16"x20" (38x38cm/ 40x50cm) |

| Controller | GY-06 Digital Time & Temp. Control |

| Printable Articles | Up to 5mm Thickness |

| Opening Angle | 50 Degrees |

| Gas Spring Control | Yes |

| Voltage | 110V/ 220V |

| Power | 1600W/ 1800W |

| Time Range | 0-999 Sec |

| Maximum Temp. | 225 C |

| Temperature Accuracy | ±0.5% |

| Packing Size | 93x54x60cm/91x55x59cm |

| Gross Weight | 49kg/56kg |

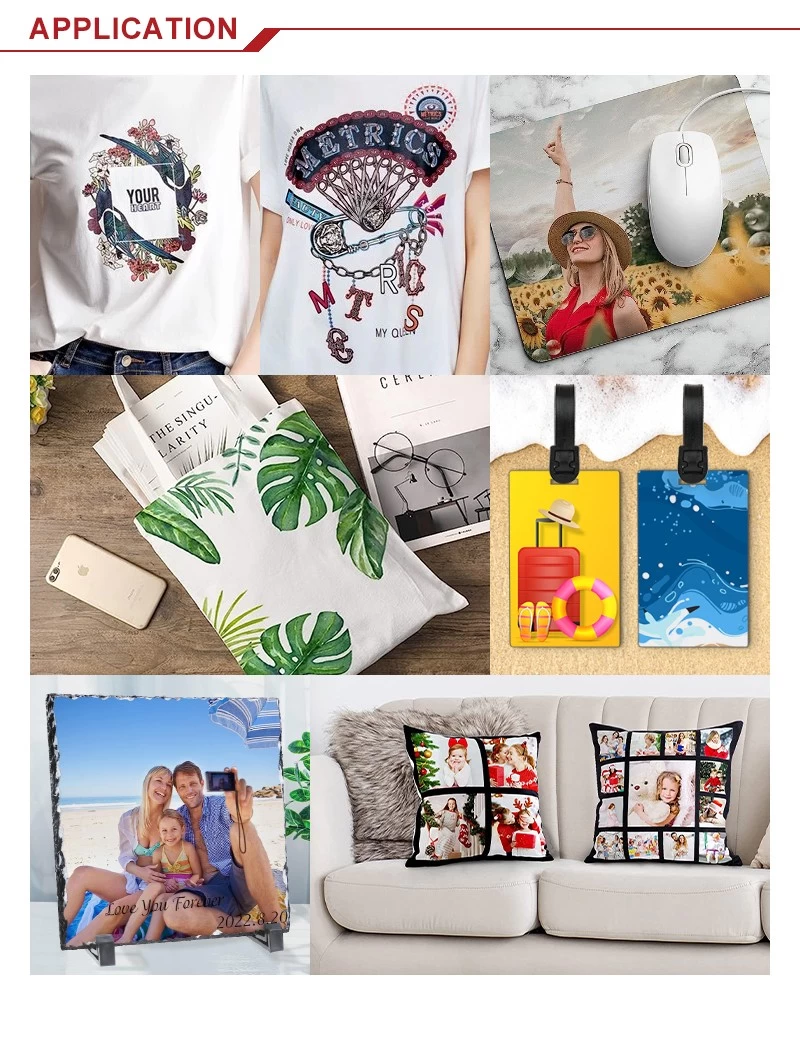

TC Auto Open Heat Press with Detachable Control Box is a versatile and efficient solution that finds applications in a wide array of industries, including the apparel and promotional products sector, crafting and hobbyist communities, and businesses involved in sublimation printing and garment customization.

It is suitable for any sublimable or transferable product. For example: T-shirts, MDF board, metallic sheet, slippers and other flat products.

Each Single Copper sheathed heating rod is tested before it is cast in an aluminum alloy or Mica Sheet. These heating rods are comparable to those found in industrial ovens that heat up quickly, work efficiently and last many years. With our industrial quality heat castings, you can get five years worry free warranty.

All Microtec heat presses are strictly tested under the following procedures before shipping out.

1) Turn on the machine, let it heating up to 200 degree Celsius.

2) Keep the temperature stay at 200 degree Celsius for at least 20 minutes.

Microtec's main objective is to support all our customers, who can manage their heat transfer activities without interruption. So Microtec offers FREE SPARE PARTS with a quantitative order and the following guarantee:

* Free lifetime technical support on all heat press machines.

* Two-year warranty

* Five-year warranty on fusions and welds.

* Five-year warranty on the heating plate.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF