|

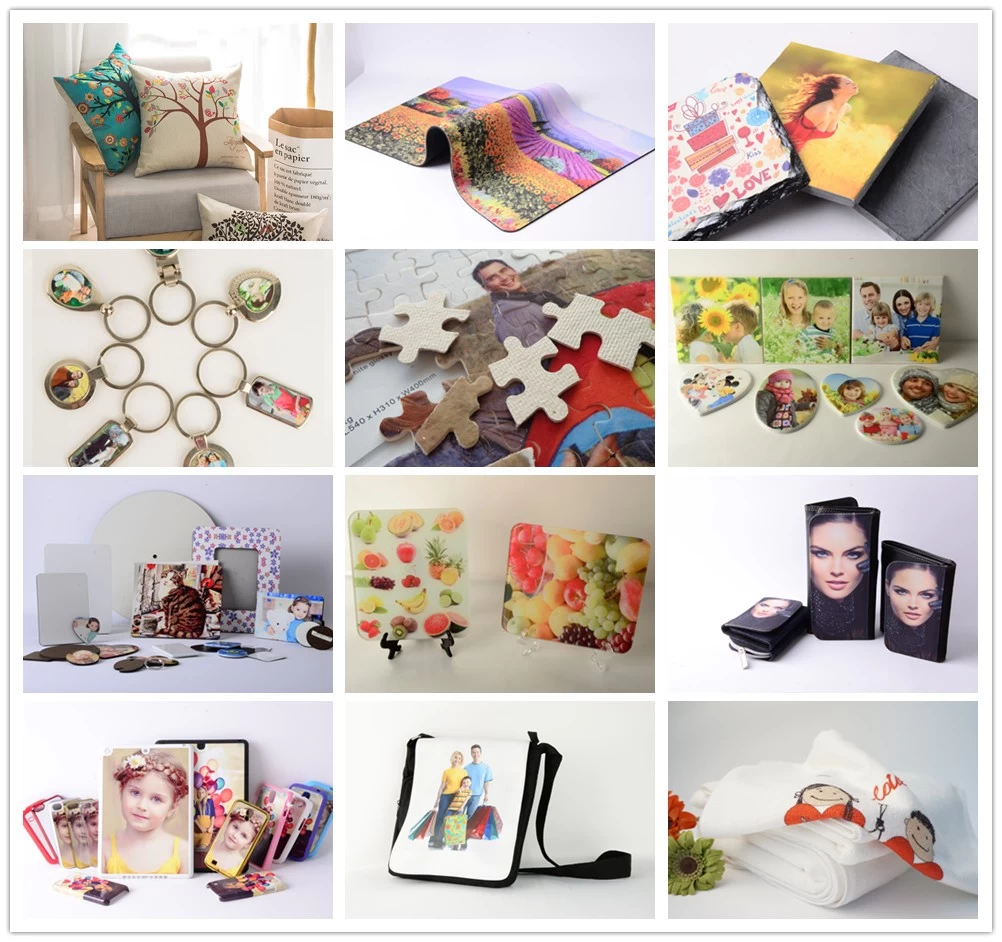

The SENKO-15A and SENKO-20A models represent the streamlined version of the SENKO auto open heat press series. These simple yet efficient machines are perfectly tailored for T-shirt sublimation businesses, as well as for transferring designs onto jackets, mouse pads, tiles, and other items.

These models are characterized by their straightforward design, focusing on ease of use and efficient functionality, making them ideal for businesses looking for a reliable, no-fuss solution. Both the SENKO-15A and SENKO-20A are constructed with the highest grade components, ensuring professional-level performance and durability. And the auto-open feature frees up your hands during the pressing process, allowing for multitasking and improving workflow efficiency.

In summary, the SENKO-15A and SENKO-20A auto open heat presses are ideal for those in the sublimation printing business seeking a straightforward, efficient, and reliable machine. Their ease of use, coupled with the capability to produce high-quality transfers, makes them a valuable asset for any print shop focusing on varied sublimation projects.

|

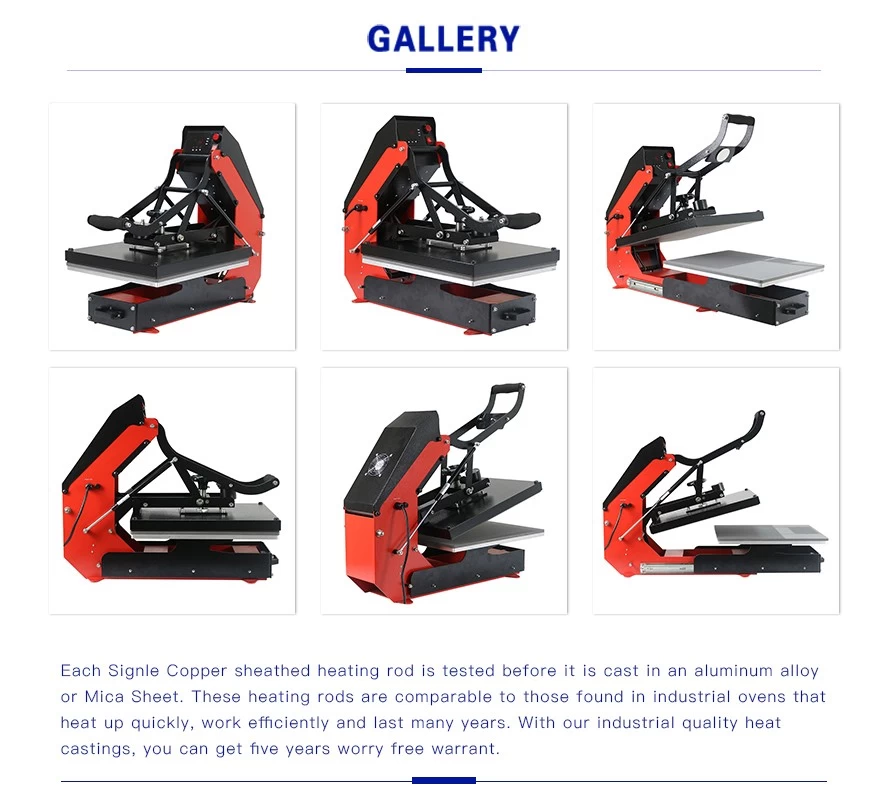

Easy Pressure Adjustment: A rotating knob enables simple pressure setting adjustments before, during, or after the heat press procedure, offering flexibility and control. |

|

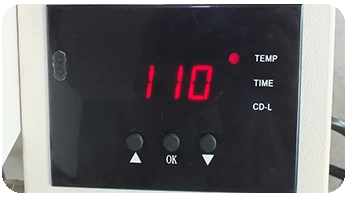

GY-04 Digital Controller: Fully digital controls and display allow simple operation and setup for the simple senko auto open heat press. |

|

Slide-out Press Bed: You can easily slide out the press bed with the handle, which makes it easier and more convenient for operation. |

|

Ergonomic Handle: The ergonomic handle makes the T-shirt sublimation printing machine easy for anyone to make the operation. |

| Model No. |

SENKO-15A |

SENKO-20A |

| Machine Type |

Auto Release, Clamshell |

| Platen Size |

15''x15'' (38x38cm) |

16''x20'' (40x50cm) |

| Under Plate |

Draw-out & Exchangeable |

| Controller |

GY-04 Digital Time & Temp. Control |

| Printable Articles |

Up to 8mm Thickness |

| Opening Angle |

25 degrees |

| Gas Spring Control |

Yes |

| Voltage |

120V/ 220V |

| Power |

1800W |

| Time Range |

0-999 sec. |

| Maximum Temp. |

225 C |

| Packing Size |

89x54x75cm |

90x55x76cm |

| Gross Weight |

57kg |

65kg |

The SENKO series sublimation heat press is apable of handling a wide range of items beyond T-shirts, the SENKO is a versatile tool for various heat transfer needs, making it a popular choice globally. For example: T-shirts, MDF board, metallic sheet, slippers and other flat products.

|