Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

KP-1650 CUTTER PRO: The Ultimate Industrial-Grade DTF Film Cutting Solution

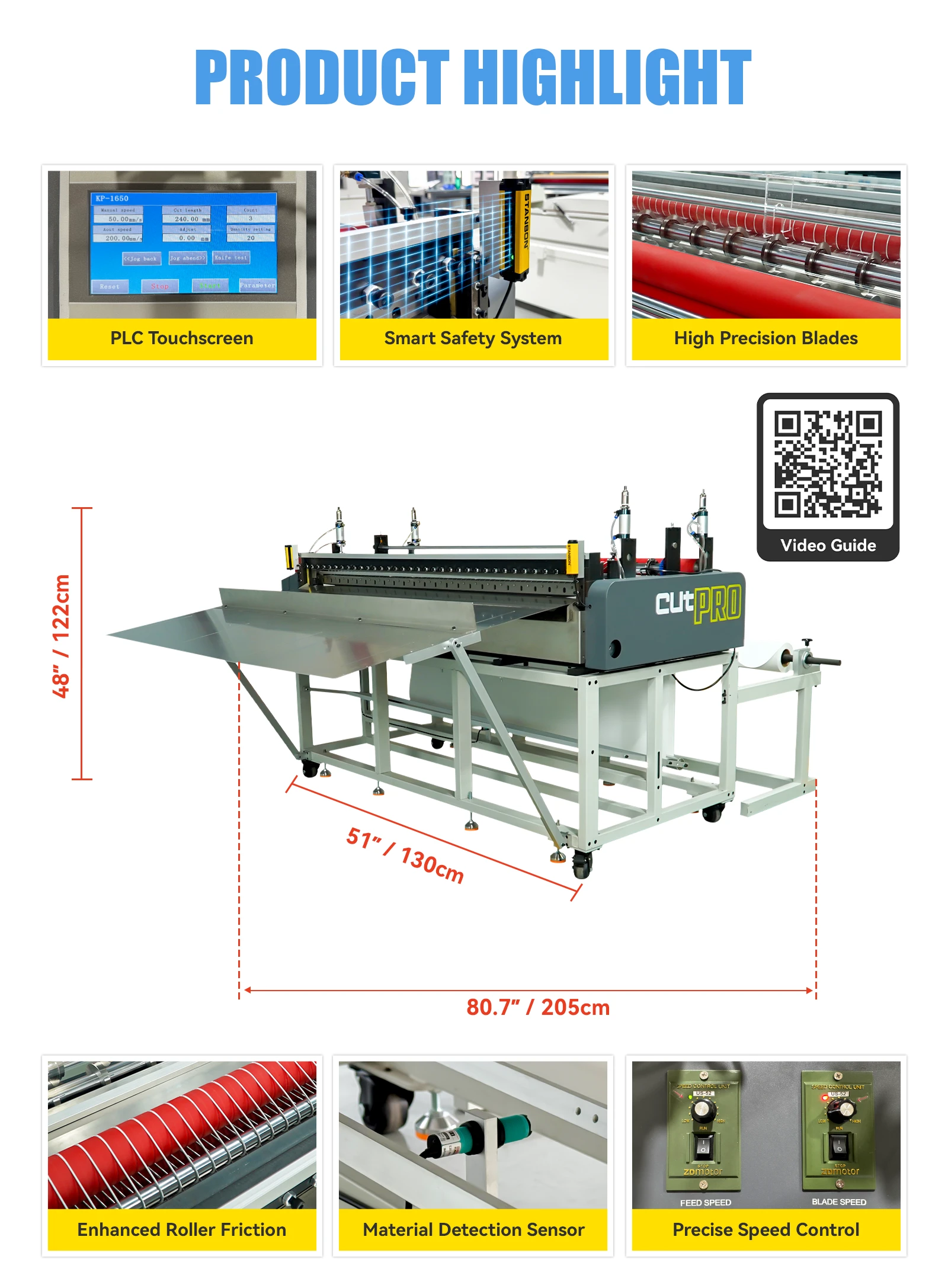

The KP-1650 Wide Format DTF Film Slitting Machine is a professional, high-efficiency cutter designed for large-format DTF film roll slitting and sheet cutting.

With a cutting width of 1650mm and support for up to 18 blades, this machine significantly improves productivity and reduces manual labor in DTF transfer film processing.

Equipped with automatic deviation correction, a coil-wrapped roller to enhance friction, and a smart sensor for automatic material detection, the KP-1650 ensures precise and stable cutting even at high speed.

The PLC control panel allows operators to easily adjust cutting speed, tension, and pressure, while the roll-to-roll feeding and collection design enables continuous, uninterrupted operation—perfect for large-scale DTF printing businesses.

Blazing Cutting Speed of 120 Meters/Minute: Achieve production speeds never before possible. Dramatically reduce turnaround times for large orders and meet the tightest deadlines with ease.

High-Capacity, Up to 18 Blades: Handle complex, multi-job production runs without stopping to change configurations. This high blade capacity ensures continuous operation for maximum uptime.

Intelligent PLC Control System: The brain of the machine ensures precise, consistent, and repeatable cuts. Easily manage complex cutting patterns and maintain perfect accuracy across every job.

Industrial Pneumatic Fixing System: Guarantees absolute material stability during high-speed operation. This eliminates shifting or misalignment, ensuring every cut is clean and precise, from the first to the last.

Automatic Material Detection Sensor: The machine intelligently senses the material, automating the feeding process and preventing errors, reducing operator intervention to a minimum.

Designed for the Smart, Safe Workshop

Smart Safety Protection System: A comprehensive suite of sensors and mechanisms protects your operators and your equipment, ensuring a secure working environment even at top industrial speeds.

Enhanced Roller Friction Design: Provides superior grip and traction for a wide variety of materials, preventing slips and ensuring a smooth, consistent feed into the cutting blades.

Feed Roller & Blade Speed Adjustment: Fine-tune the machine's performance to perfectly match the specific requirements of different materials and job types, optimizing both quality and speed.

The KP-1650 is perfect for high-volume DTF production, delivering up to 80% faster. This machine ensures continuous roll-to-roll operation, improving productivity while maintaining consistent quality.

Key Features:

1650mm Wide Cutting — Ideal for large rolls and wide-format applications.

Supports Up to 18 Blades — Enables multi-strip cutting in a single pass.

Automatic Deviation Correction — Corrects film alignment for precise cutting.

Coil-Wrapped Drive Roller — Increases friction and ensures stable feeding.

Material Detection Sensor — Automatically detects film position and triggers feeding.

Pneumatic Knife Holder — Provides fast, clean, and accurate cuts.

PLC Control Panel — Intuitive interface for adjusting speed, tension, and blade operation.

Adjustable Tension & Speed — Customizable for different materials and production needs.

Extendable Bottom Plate — Facilitates handling of garments such as T-shirts and hoodies.

Safety Features — Emergency stop switch, and robust frame for reliable operation.

At Microtec, our primary goal is to ensure that our customers can carry out heat transfer activities seamlessly. To support this, we offer FREE SPARE PARTS with qualifying orders, alongside the following comprehensive guarantees:

We are dedicated to providing long-term reliability and peace of mind for your heat transfer operations.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF