Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

ASTM-24 Double Station Industrial Pneumatic Heat Press is featured its 16''x24'' (40x60cm) double working station and air-operated system. The heat press provides production-oriented pressing with push button operation, fully digital temperature & time control, and solid steel welded frame design with an affordable automatic large format price.

The 16"x 24" double station heat press combines a heavy-duty solid industrial grade heat pressing framework with high quality electric components, and operates with a smooth drawer-style front-loading motion & high pressure top-down pneumatics with fully adjustable PSI control.

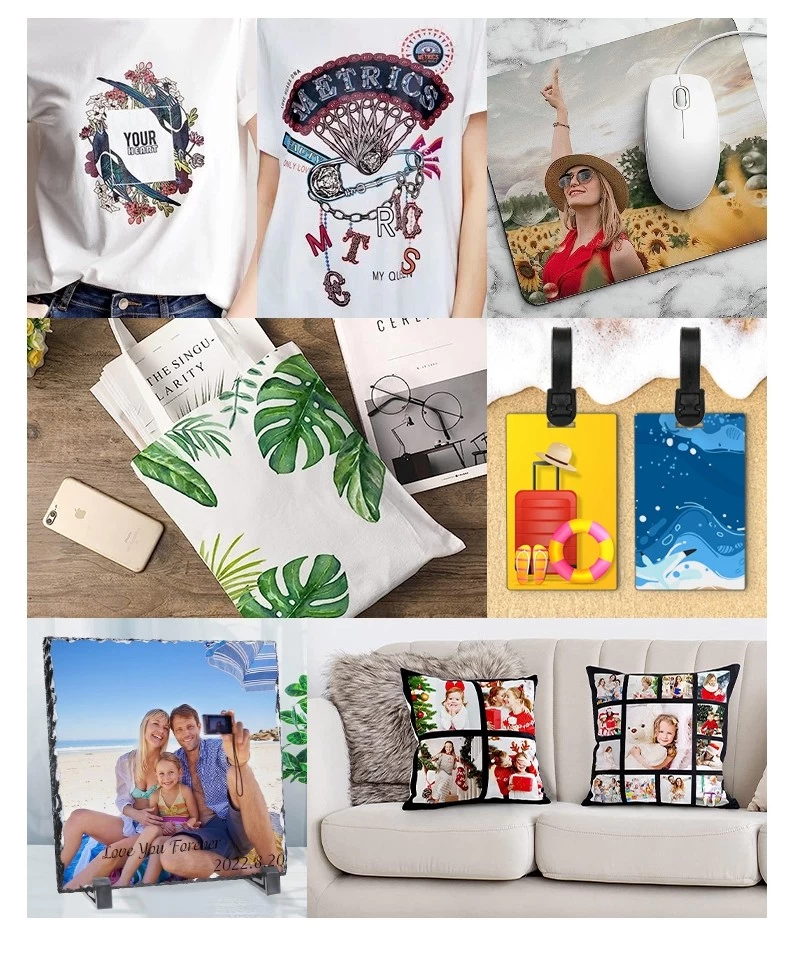

ASTM-24 automatic heat press is perfectly for heat transfer pressing fabric, complex garments, metal, wood, ceramics, glass, and more... It's the industrial-grade automatic solution between smaller platens and large format.

ASTM-24 Pneumatic Dual Heat Press key features:

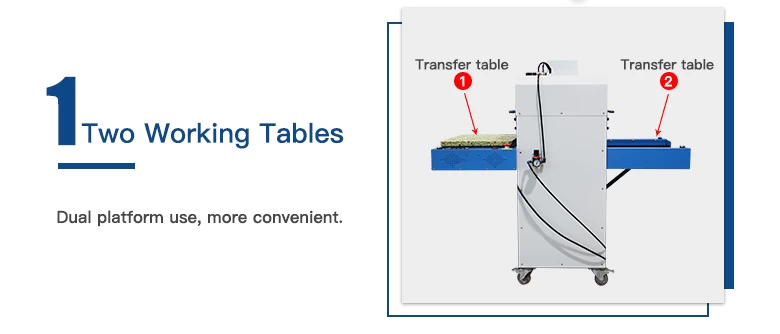

Double Stations: ASTM-24 is equipped with two working stations, allowing for simultaneous printing on two different items or locations. This feature significantly increases productivity.

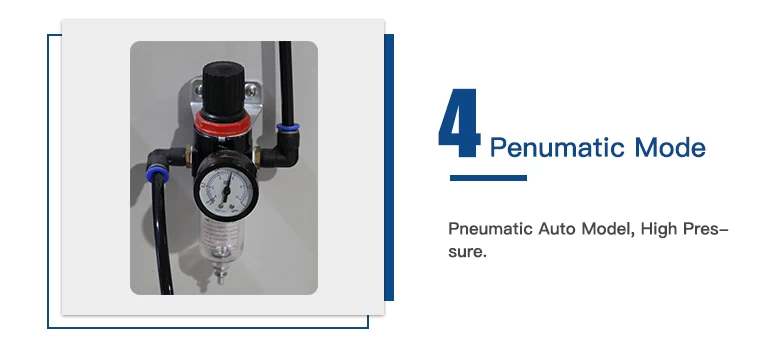

Pneumatic Operation: The heat press machine operates using a pneumatic system, which means it uses compressed air to apply consistent and even pressure to the heat platen. This ensures uniform heat distribution and excellent print quality.

Large Heat Platen: The 16''x24'' heat platen refers to the size of the heating element. This size is ideal for a wide range of applications, including T-shirt printing, heat transfers, and more.

Digital Temperature and Time Control: The ASTM-24 heat press machine is equipped with a digital control panel that allows you to set and adjust both temperature and pressing time. This precise control is essential for achieving the best results with different types of materials and transfers.

Adjustable Pressure: You can easily adjust the pressure settings to accommodate various materials and thicknesses, ensuring that the heat transfer adheres correctly without damaging the fabric or substrate.

| Model No. | ASTM-24 |

| Machine Type | Automatic, Double Station |

| Platen Size | 16"x24"(40x60cm) |

| Under Plate | Slide-out |

| Controller | GY-06 Digital Time & Temp. Control |

| Printable Articles | Up to 50mm Thickness |

| Air Compressor Required | Yes |

| Voltage | 120V/ 220V |

| Power | 1600W/ 1800W |

| Time Range | 0-999 sec. |

| Maximum Temp. | 225 C |

| Temperature Accuracy | ±0.5% |

| Packing Size | 148x93x148cm |

| Gross Weight | 278kg (Wooden Package) |

ASTM-24 is ideal for use on apparel, paper, hard and soft goods, T-shirts, signs, koozies, sublimation and more. Great for DTG, vinyl, printed transfers, leather, heat seal patches, foil and other special effects.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF