Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

|

Fully Automated System This auto heat press machine allows you to liberate your hand. It is fully automated, providing consistent and precise heat application without the need for manual intervention. Adjustable Pressure The pressure can be adjusted from 0-10 to meet different sublimation needs. Upgraded motor The electric heat press with upgraded motor has lower noise when running. Fully Pull-out Bottom Plate The fully pull-out bottom plate allows for quick and easy placement of materials, minimizing the risk of damage and ensuring consistent results. Wide Opening Angle & Safety The Clamshell Auto Heat Press boasts a generous opening angle, making it easy to load and unload materials without the risk of burning or scalding. The opening height is about 15cm (6 inches). There will be ± 2~3cm differences depending on the local voltage. Additionally, users can press the button "Reset" to make the machine stop working at once if there is any emergency. High-efficient & Cost-effective This clamshell auto heat press can shut down in a fast speed and heat up fast as well as distribute heat evenly. It also offer excellent value for money, with a reasonable price point that makes it an affordable investment for businesses of all sizes. |

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

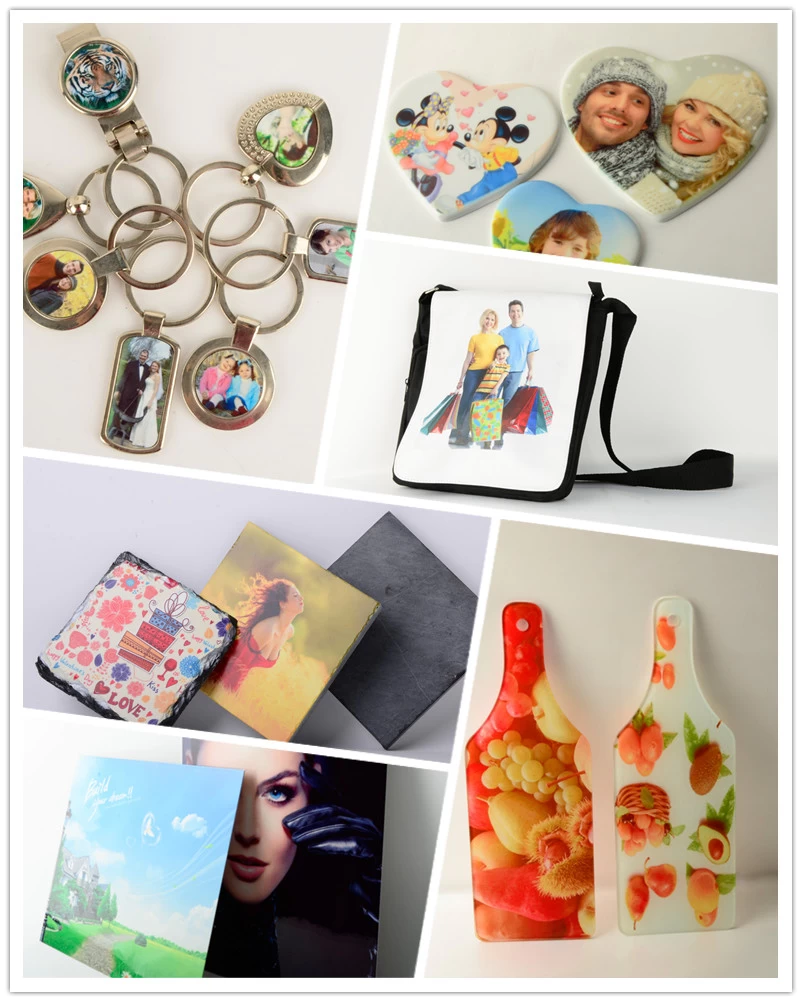

This Electic Full Auto Heat Press Machine is suitable for any sublimable or transferable product. For example: T-shirts, photo frames, slippers and other flat products. |

|||||||||||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

Microtec's main objective is to support all our customers, who can manage their heat transfer activities without interruption. So Microtec offers FREE SPARE PARTS with a quantitative order and the following guarantee:

* Free lifetime technical support on all heat press machines.

* Two-year warranty

* Five-year warranty on fusions and welds.

* Five-year warranty on the heating plate.

* Six-monthly warranty on the heaters of cups, plates and caps.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF