Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

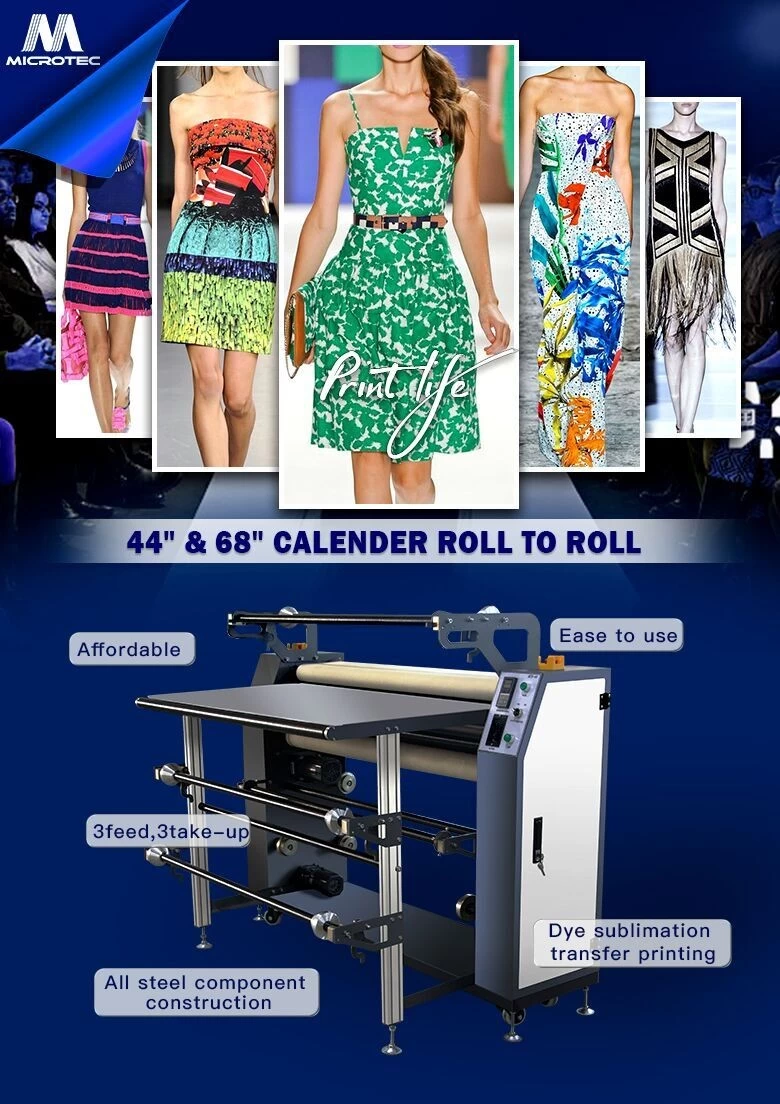

In response to the escalating demand for precision cut-piece digital printing, Microtec proudly presents its innovative Multifunctional Oil Heating MTX series Rotary Thermal Transfer Machine. This cutting-edge roll-to-roll heat transfer printing solution offers a seamless and efficient approach to tackling large-scale printing projects. With its affordability and ease of management, the MTX-44 stands as the ultimate answer for all your dye sublimation paper transfer needs, making it versatile for continuous or roll materials.

What sets the MTX-44 apart is its state-of-the-art oil heating system, which ensures a consistent heat distribution across the drum's width while optimizing energy consumption. Remarkably, this system operates with an astonishing 50% reduction in energy usage compared to its electrically heated counterparts. The Microtec 44'' Calender rotary heat press serves as the quintessential tool for transferring impeccably detailed images onto polyester fabrics, roll-to-roll applications, and precision cut-sheet projects. From vibrant dye sub banners to soft signage, displays, cut and sew dye sub applications, sportswear, fitness garments, and beyond, the MTX-44 promises unmatched quality and versatility. Step into a new era of digital printing with the Microtec MTX-44.

Microtec MTX Calenders don't just offer exceptional performance. They're also highly cost-effective and easy to manage. With a robust all-steel construction, you can trust in their durability for year-on-year production.

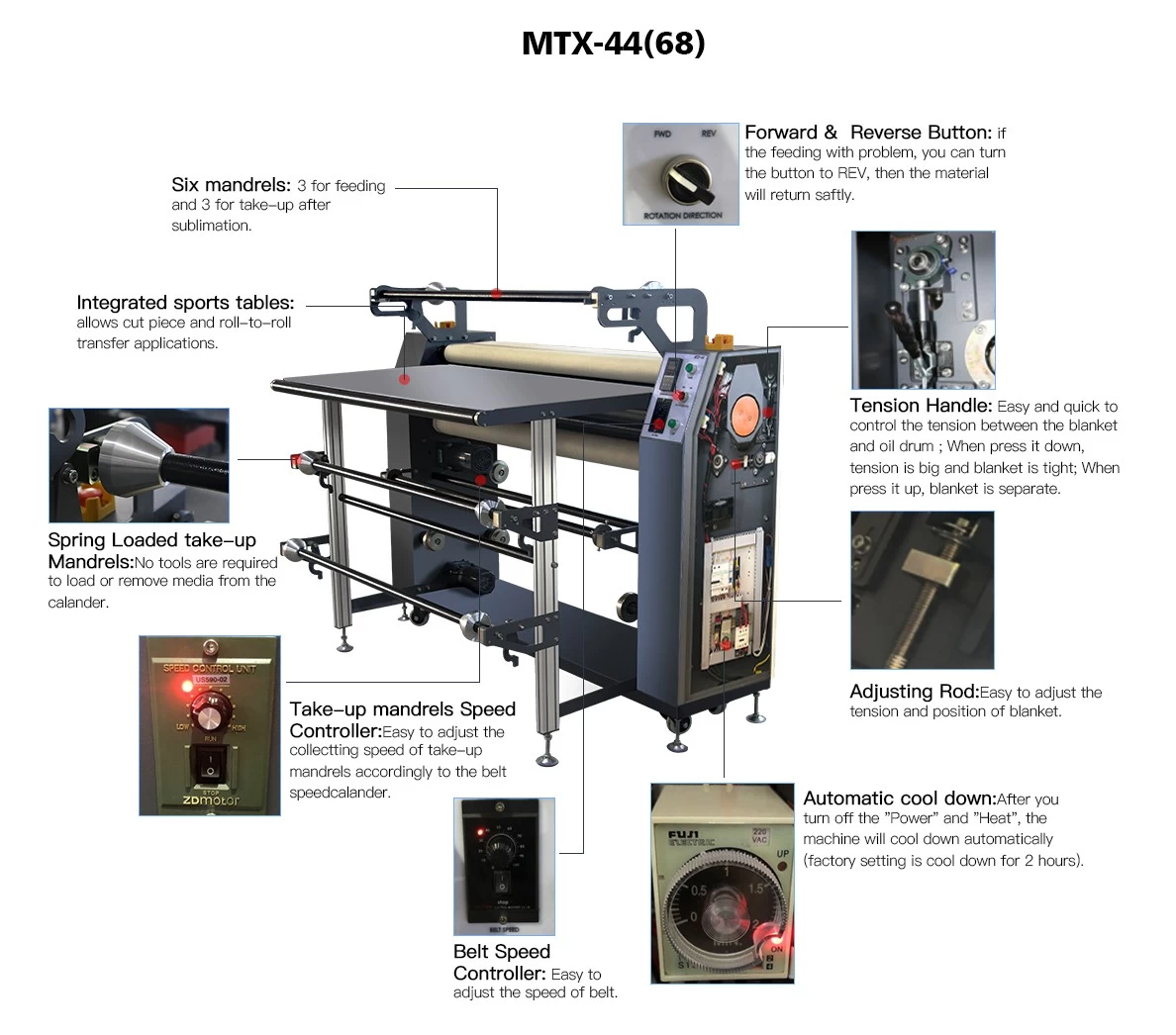

Key Features of Microtec MTX Calenders:

Integrated Sports Tables: These tables facilitate both cut-piece and roll-to-roll transfer applications.

Six Mandrels: Three for feeding and three for take-up after sublimation, ensuring smooth operation.

Spring-Loaded Take-up Mandrels: No tools required for loading or removing media from the calender.

Forward & Reverse Button: Easily resolve feeding issues by switching to the reverse mode.

Tension Handle: Quickly control the tension between the blanket and oil drum for precise results.

Adjusting Rod: Easily fine-tune the tension and position of the blanket.

Belt Speed Controller: Adjust the speed of the belt to suit your specific requirements.

Take-up Mandrels Speed Controller: Ensure optimal collecting speed for take-up mandrels, synchronized with the belt speed.

Automatic Cool Down: After powering down and switching off the heat, the machine automatically cools down (factory setting is a 2-hour cooldown period).

| Model No. | MTX-44 | MTX-68 |

| Max. Working Width | 44" (1200mm) | 68" (1730mm) |

| Dia of Drum | Φ7.8" (200mm) | Φ9.8" (250mm) |

| Max. Temperature | 392℉ (200℃) | 392℉ (200℃) |

| Heating Elements | 1 | 3 |

| Heating Media | Thermal Oil Heating | |

| Controller | Digital Temperature & Time Control | |

| Max. Feeding Speed | 0-1100mm/min | 0-1200mm/min |

| Number of Mandrels | 6 mandrels, 3 feed, 3 take-up | |

| Max. Material Roll Dimension | 350mm | |

| Max. Roll Weight | 45kg | |

| Voltage | 220VAC 50HZ Single Phase | 220VAC 50HZ Three Phase |

| Current | 27A | 30A |

| Power | 6KW | 11KW |

| Noise Level | 30DB | 30DB |

| Net/Gross Weight | 450kg/ | / |

| Machine Size | 163x98x132cm | 230x130x151cm |

| Packing Size | 183x120x163cm | 248x145x183cm |

MTX Calenders are available for both roll-to-roll and piece-to-roll applications, making them versatile tools for various production needs. Whether you're printing continuous materials or dealing with cut pieces and rolls, Microtec's MTX Calenders are your trusted solution for precise temperature fixation and efficient production, saving you valuable time and effort.

Sublimation Applications:

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF