In the fast-growing DTF (Direct-to-Film) printing industry, automation is no longer a luxury — it's a necessity for staying competitive. With demand for custom apparel and on-demand printing at an all-time high, businesses are seeking efficient, scalable, and intelligent solutions to meet production needs without increasing labor costs.

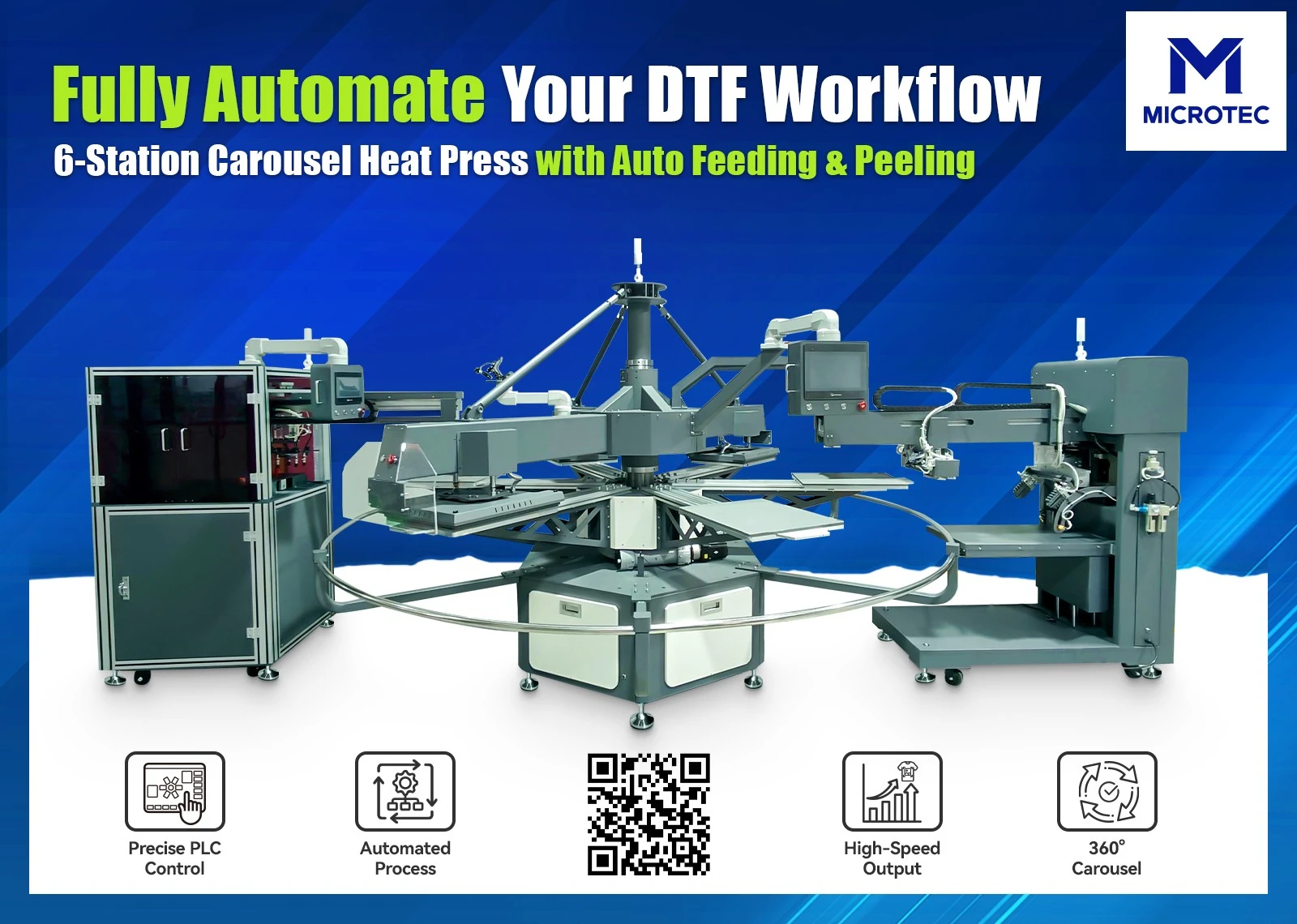

Microtec’s latest breakthrough — the X6 Automated Carousel Heat Press, combined with SSE-001 and SSE-002 — delivers a truly end-to-end DTF automation solution.

The X6 is a 3-head, 6-station automatic carousel heat press engineered for continuous, high-volume DTF transfers. When integrated with:

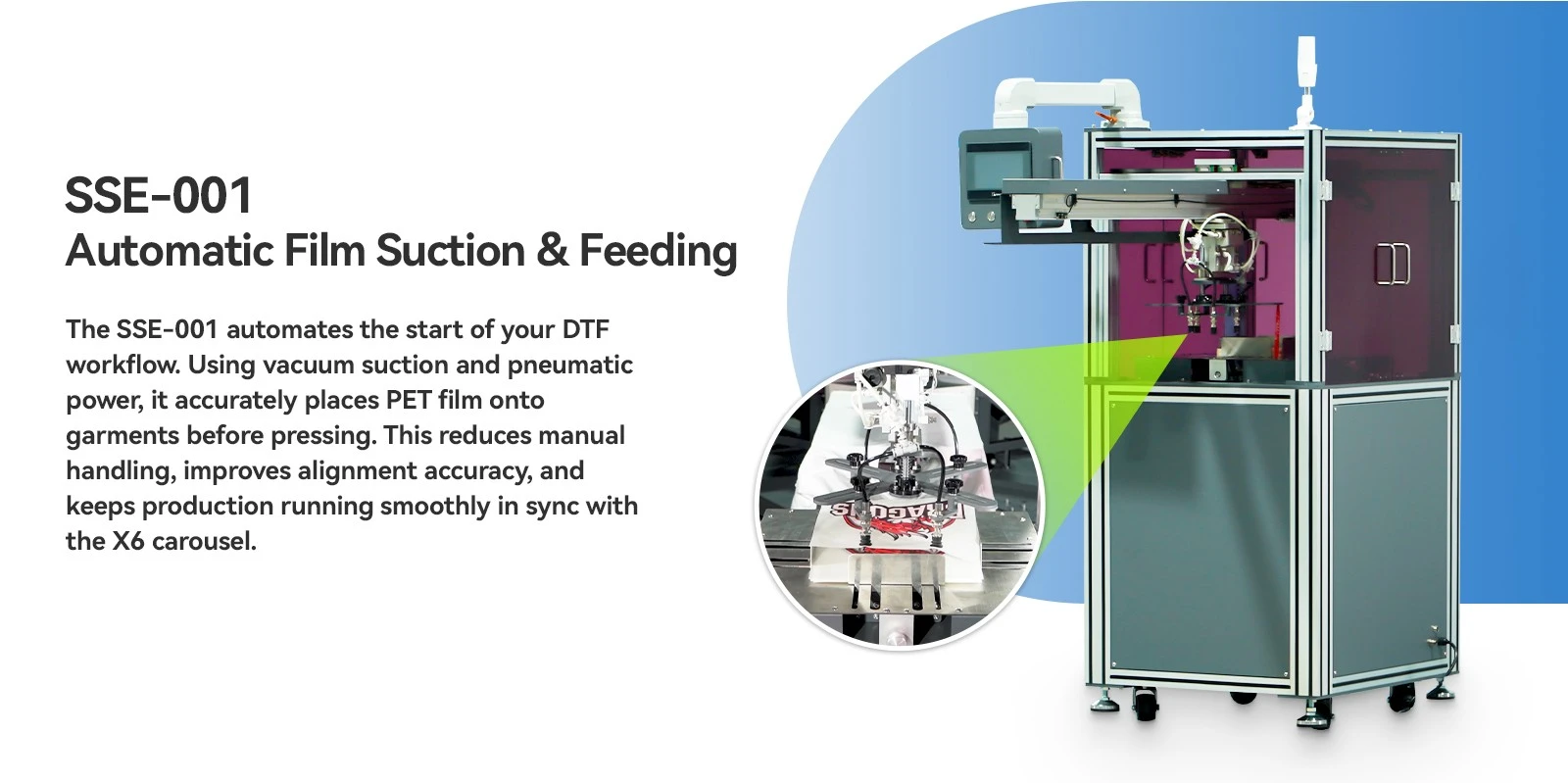

SSE-001: Automatic Film Suction & Feeding Machine

SSE-002: Automatic Film Peel-Off & Collection Machine

...you get a fully automated workflow — from feeding to pressing to peeling and collecting, all handled by machines with minimal human involvement.

✅ Smart PLC Touchscreen & Infrared Laser Positioning

✅ Fully synchronized film feeding, transfer, and peel-off

✅ Consistent pressure & temperature across all stations

✅ Modular configuration: scale up from X4/X6 to X8

✅ Ideal for high-volume custom apparel and textile factories

With the DTF industry projected to grow by over 12% annually through 2027 (source: market research), automation is the key to sustainable scaling. The X6 System helps you:

Cut labor costs by up to 70%

Increase output efficiency by 2–3X

Minimize human error in alignment, temperature, and film peeling

Future-proof your production for high-mix, on-demand orders

Whether you're currently using manual or semi-automated systems, Microtec’s X6 with SSE modules provides the fastest path to full automation — without the complexity or cost of large robotic lines.