The custom mug market is booming. With global Print-on-Demand (POD) sales reaching record highs, personalized mugs have become one of the top-selling POD products, especially across platforms like Etsy, Amazon, and Shopify.

To help businesses meet increasing demand while reducing labor and error, Microtec introduces a complete mug automation solution — combining:

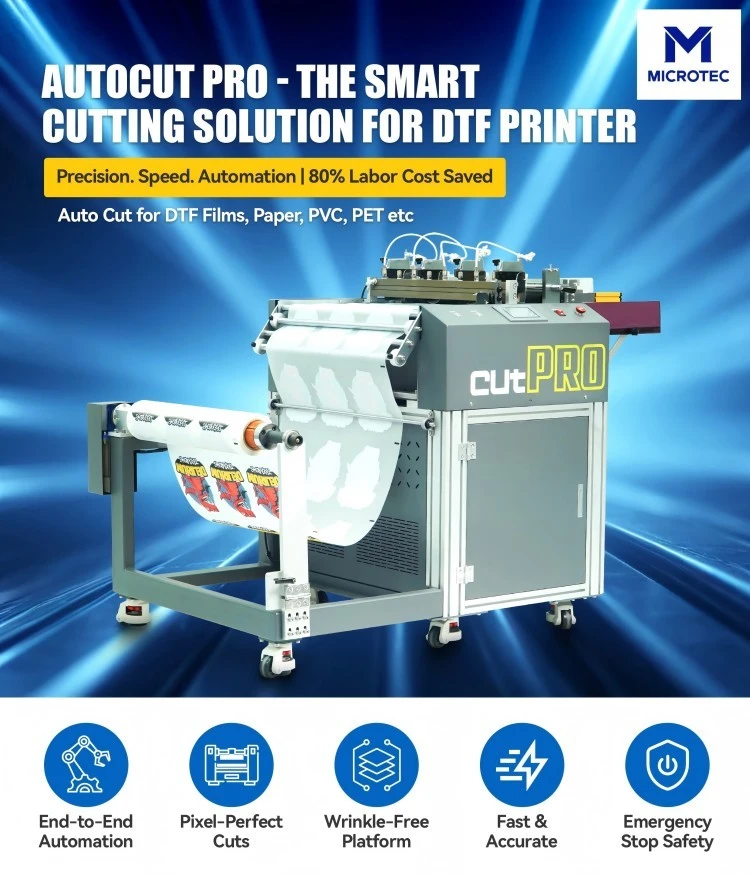

KP-650 Smart Cutting Machine – For precise film/paper cutting

MWM-10 Auto Mug Wrap Machine – For fast, uniform paper application

M15 Robotic Mug Heat Press – With 15 stations for continuous, high-volume mug transfers

Together, these three machines automate the entire mug decoration process — from film cutting to wrapping to transfer — enabling end-to-end efficiency with minimal human intervention.

15-station robotic heat press — 250+ mugs/hour output

Intelligent PLC control with precision heat/pressure management

Robotic mug feeding & gripping system for seamless transfer

Full-wrap mug heating technology for perfect edge-to-edge prints

Scalable setup with options for 5, 10, or 15 stations

Integrated cooling system for improved efficiency & safety

According to industry research, custom drinkware accounts for over 60% of high-volume POD orders, and the average fulfillment time is becoming a competitive factor. Manual and semi-auto workflows are struggling to keep pace with:

Mass-order processing

Tight shipping windows

Error-free printing at scale

With the M15 system, businesses can now triple their output while reducing dependency on skilled labor. Whether you're running a POD fulfillment center or a large promotional print shop, this system positions you for growth, speed, and consistency.