Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

Introducing the LZP-40-DH+ODA Lanyard Heat Press Machine with Automatic Feeding Device, a state-of-the-art solution designed to elevate your lanyard heat transfer process. This advanced machine combines efficiency, precision, and user-friendly features to meet the demands of high-volume production without compromising on quality.

Dual Heat Platens: Equipped with two 100x25 cm heating platens, allowing simultaneous double-sided transfers for increased productivity.

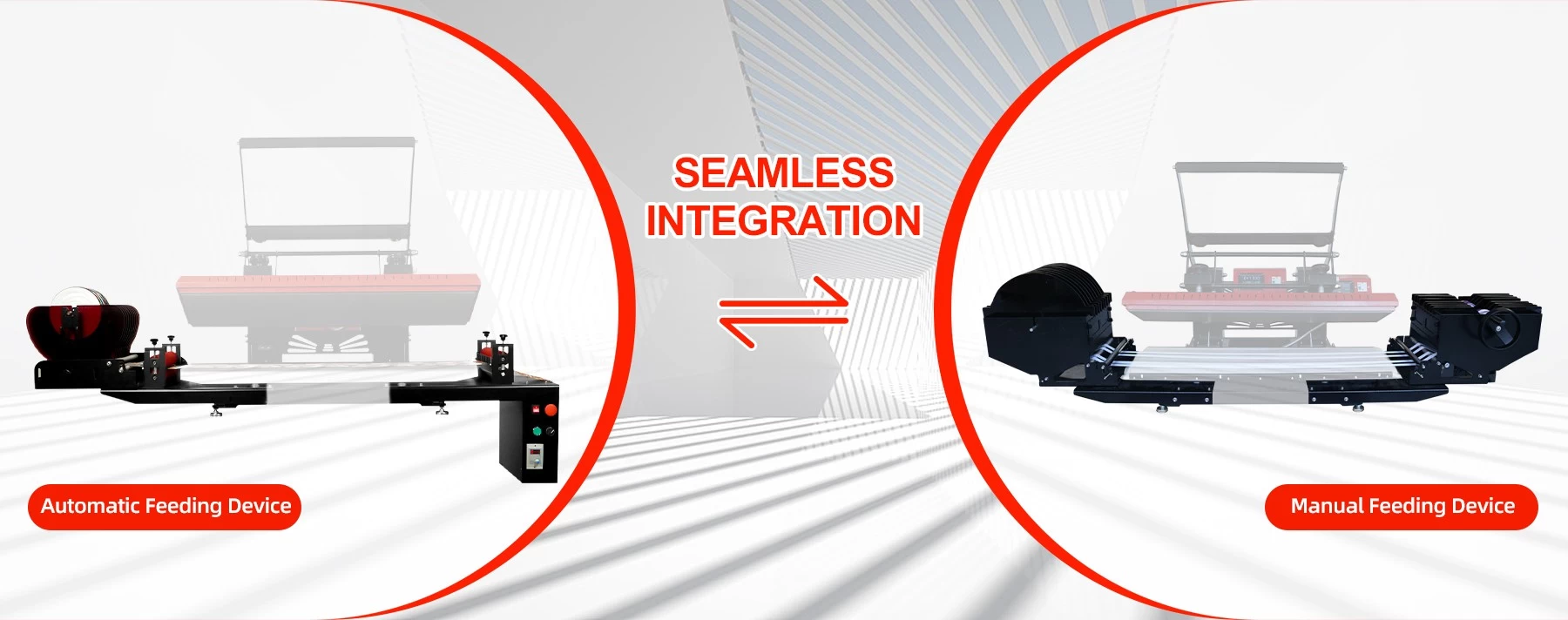

Automatic Feeding Device: The integrated ODA Automatic Feeding Device streamlines operations by swiftly winding lanyards post-transfer, reducing downtime and preparing for the next cycle efficiently.

Adjustable Feeding Speed: Customize the feeding speed to match your specific requirements, ensuring smooth and consistent results every time.

User-Friendly Controls: Features two GY-06 Digital Time & Temperature Controllers for precise adjustments, accommodating various materials and transfer conditions.

Versatile Compatibility: Suitable for lanyards of varying widths, including 12mm, 20mm, and 25mm, making it adaptable to diverse production needs.

Durable Construction: Built with high-quality materials to ensure long-lasting performance and reliability in demanding production environments.

Model No.: LZP-40-DH+ODA

Machine Type: Auto Open with Double Heat Platens and Automatic Feeding Device

Platen Size: 2 pieces, each 100x25 cm

Controller: 2 x GY-06 Digital Time & Temperature Control

Woollen Felt: 1050x310x3 mm

Feeding Device Compatibility: Suitable for 12/20/25 mm widths

Voltage: 220V

Power Consumption: 4.85 KW

Time Range: 0-999 seconds

Maximum Temperature: 225°C

Machine Dimensions: 218x83x54 cm

Packaging Dimensions: Machine: 120x95x61 cm; Feeding Device: 120x68x70 cm

Net Weight: Machine: 128 kg; Feeding Device: 75 kg

Gross Weight: Machine: 168 kg; Feeding Device: 100 kg

Certification: CE Approved

By integrating the LZP-40-DH+ODA into your production line, you'll experience enhanced efficiency, reduced downtime, and consistent, high-quality results. This machine is the ideal choice for businesses aiming to scale up their lanyard production while maintaining exceptional standards.

At Microtec, our primary goal is to ensure that our customers can carry out heat transfer activities seamlessly. To support this, we offer FREE SPARE PARTS with qualifying orders, alongside the following comprehensive guarantees:

We are dedicated to providing long-term reliability and peace of mind for your heat transfer operations.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF