Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

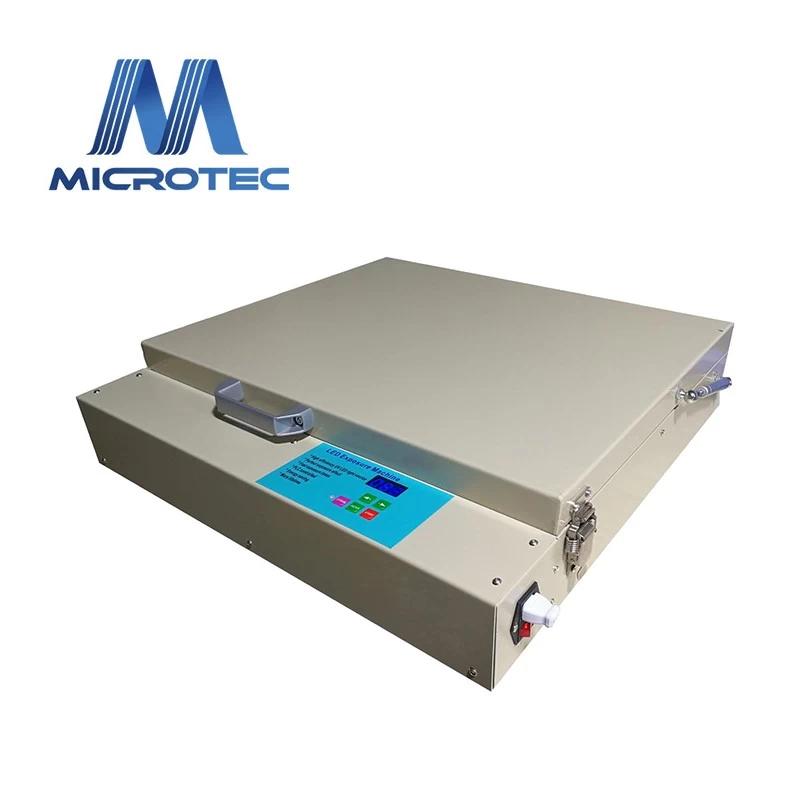

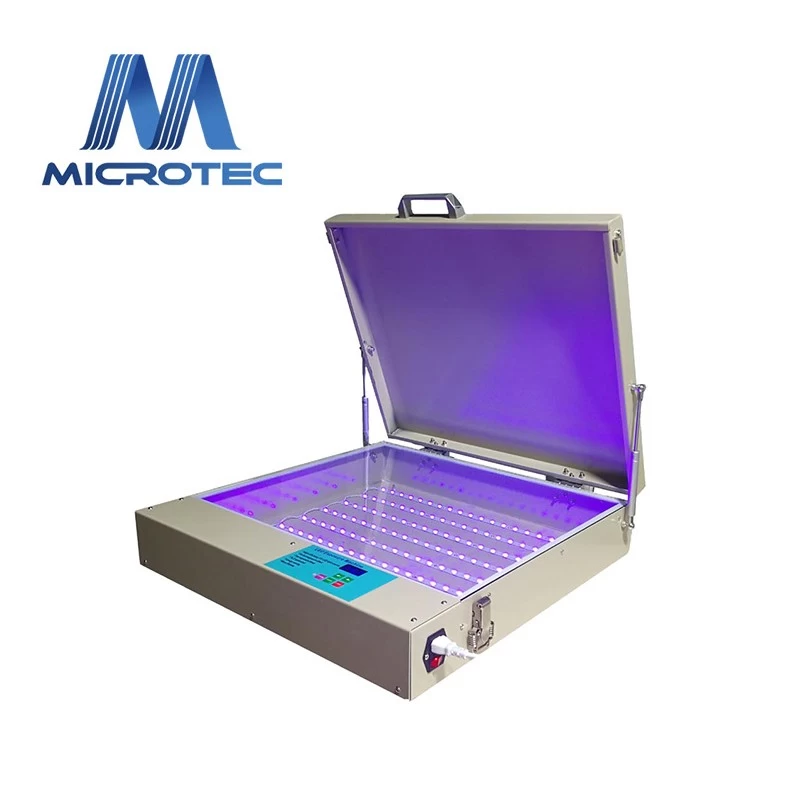

This machine adopts intelligent digital control. The exposure time is more accurate, meanwhile,with the design of small volume,compact structure, stable light source, ability of working normal with low voltage, and good correspondency between the wavelength and the photosensitive material,making the texts and images clear and increasing the print rate.

High efficiency and energy saving are the most prominent features of LED printers. The actual trial printing speed is several times than other light sources.

*Adopting high efficiency UV LED light source,which save 50% electricity than ordinary model

*PLC controlled panel, very easy to operate

*Automatic memory function for working as original seting next time

*Perfect exposure effect because of LED light

*Fast exposure time,about 40-70 seconds

*Energy saving and environment friendly

*Stable exposure quality,more lifetime

*Durable and beautiful with steel coat

*Outside connecting power plug, safety and convenience

*Easy to transport,LED light is not fragile in delivery

| Model No. | MT-EP03 |

| Max. Exposing Area | 520*610mm |

| Voltage (single phase ) | 220V or 110V |

| Time Control | 0-999s |

| Power of Lamps | 80W (8 10w UV LED-line) |

| Packing Size | In One Carton(750*680*200mm) |

| Weight | 30kg |

The LED exposure unit is used in the filed of plate-making such as pad plate, screen plate, hot stamper plate, resin plate. When you put the film onto the plate into UV LED exposure machine, start it, the emulsion on the plate will appear a unseen imagine. This is important process on all plate-making technology.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF