Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

E4 4-Station Automatic Label Placement Heat Transfer Machine

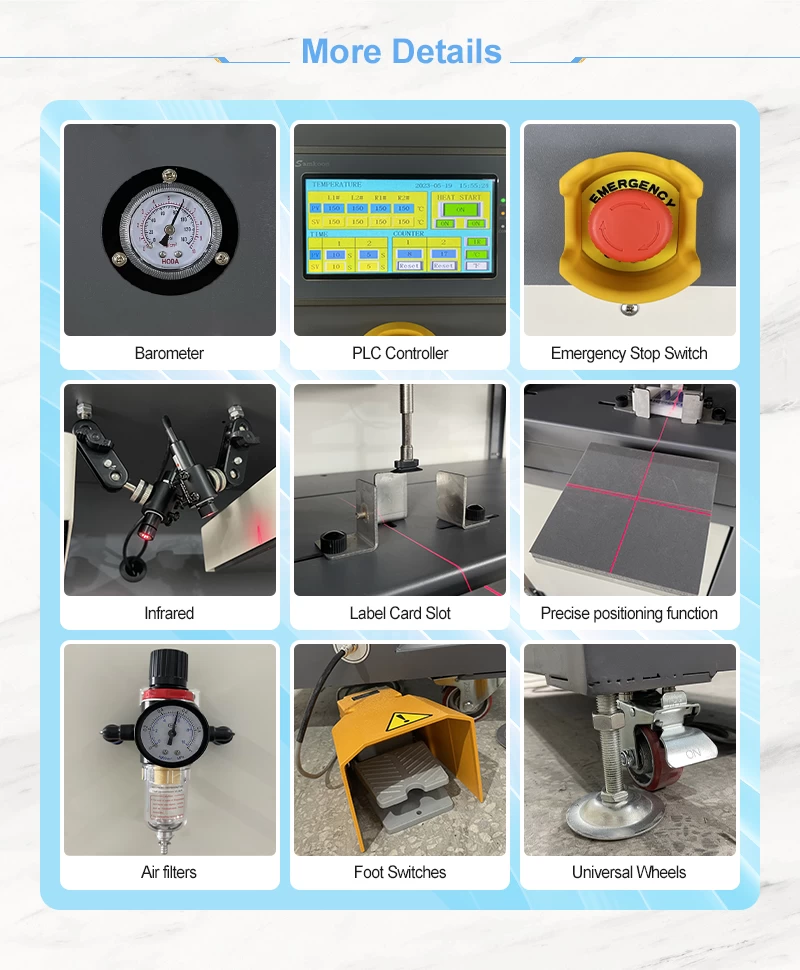

E4 is a fully automatic pneumatic labeling machine, using Microtec's latest touch screen PLC controller for more precise temperature control. 4 working stations to improve efficiency, 2 start modes(start by hands or foot switch). Adopt infrared positioning principle to realize automatic positioning transfer function, very easy and user-friendly for users to operate compared with manual heat press. It is the optimal option for industry use or commercial use, such as OEM, batch transfer printing.

Each working stations size: 15x15cm, 2 working stations on the left and 2 on the right are controlled by one PLC controller. In addition to the infrared positioning transfer function, it also with fixed label card slot, the machine automatically sucks the label onto the transfer material, and then presses down to complete the transfer.

Specification

| Model No. | E4 |

| Machine Type | 4 working stations (15X15cm), Automatic, pneumatic |

| Controller | PLC touch screen controller |

| Under Plate | Fixed |

| Printable Articles | Up to 20mm Thickness |

| Air Compressor Required | 0.7MPa/16L |

| Power | 4KW |

| High Pressure | High Pressure |

| Maximum Temp. | 230ºC |

| Temperature Accuracy | ±0.5% |

| Voltage | 120V / 220V, Single-phase |

| Frequency | 50/ 60HZ |

| Net Weight | 170KG |

| Gross Weight | / |

| Machine Size | 116x60x170cm |

| Carton Size | 128x73x189cm |

| Certification | CE Approval |

| Warranty | Two-year warranty on entire press & parts |

Our Services

Each sales staff is reachable via E-mail and Instant messaging system

Considerable After-Care ServiceVideo guide, easy-to-use graphically user’s manual

One-stop service

Customers can source all the relative sublimation products in Microtec

Machine Warranty:

Microtec's primary service goal is to support all of our customers, could deal with their heat transfer business without interruptions.

So Microtec offers FREE SPARE PARTS with quantity order and the following warranty:

*Free lifetime technical support on all heat presses.

*Two-year warranty on entire press & parts.

*Five-year warranty on castings and welds.

*Five-year warranty on heat platen.

*Half- year warranty on mug, plate and cap heaters.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF