Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF

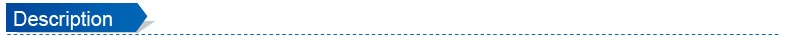

E4 Automatic Label Placement heat press features two sets of heating plates, with each set consisting of two 15x15cm working platforms. This innovative design effectively combines 4 functions into a single unit, providing a versatile 4-in-1 solution. With its PLC touch screen control and infrared positioning system, only one person is needed to operate the machine, leading to significant labor savings. Moreover, it greatly enhances production capacity and work efficiency.

1. E4 Label printing heat press machine incorporates a highly secure operating mechanism: The upper heating plates can be activated to exert downward pressure by simultaneously pressing the buttons with both hands. Alternatively, users can utilize the foot pedals (left/right) to control each set of heating plates. This dual control system ensures maximum safety during operation.

1. E4 Label printing heat press machine incorporates a highly secure operating mechanism: The upper heating plates can be activated to exert downward pressure by simultaneously pressing the buttons with both hands. Alternatively, users can utilize the foot pedals (left/right) to control each set of heating plates. This dual control system ensures maximum safety during operation.

2. Pneumatic Operation with Automatic Tag or Label Placement: E4 features pneumatic operation, providing seamless and efficient functionality. One of its remarkable capabilities is the automatic suction of stickers and precise placement onto the transfer material. This is made possible through the integration of infrared positioning technology.

3. Mobility with Swivel Casters: E4 Label Placement Heat Transfer Machine is equipped with swivel casters, enabling effortless movement of the workstation. This feature allows for convenient relocation of the machine within the workspace.

By incorporating this mobility feature, our machine offers enhanced convenience, adaptability, and versatility, making it a valuable asset for any workspace requiring frequent repositioning or reconfiguration.

| Model No. | E4 |

| Machine Type | Automatic, 4 Stations |

| Platen Size | 4 x 15*15cm Platen for Label Printing |

| Controller | PLC touch screen controller |

| Printable Articles | Up to 20mm thickness |

| Air Compressor | 0.7MPa/16L |

| Voltage | 110V/ 220V |

| Power | 4KW |

| Frequency | 50/ 60HZ |

| Time |

0-999 sec. |

| Maximum Temp. | 230ºC |

| Machine Size | 116*60*170cm |

| Packing Size | 128*73*189cm |

| Net Weight | 171kg |

| Gross Weight | 240kg |

| Certification | CE Approved |

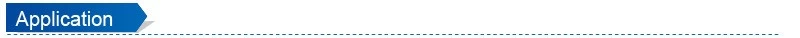

E4 Automatic Label Placement heat press is perfect for applying various labels or tags onto cloth, piece of fabric, T-shirts etc. This Heat press label attaching technology helps saving labor cost and increasing the productivity.

Our Services

Each sales staff is reachable via E-mail and Instant messaging system

Considerable After-Care Service

Video guide, easy-to-use graphically user’s manual

One-stop service

Customers can source all the relative sublimation products in Microtec

Machine Warranty:

Microtec's primary service goal is to support all of our customers, could deal with their heat transfer business without interruptions.So Microtec offers FREE SPARE PARTS with quantity order and the following warranty:

*Free lifetime technical support on all heat presses.

*Two-year warranty on entire press & parts.

Tel:+ 86-13924604227

Wechat:+ 86-13924604227

Contact Person:Sophia

PDF Show:PDF