The M15 stands out with its cutting-edge features tailored for high-efficiency mug production:

15-Station Robotic Workflow: With 15 stations operating simultaneously, the M15 can process over 250 mugs per hour, slashing production time by up to 60% compared to traditional presses. This makes it ideal for bulk orders and POD businesses.

Fully Automatic Operation: Powered by a state-of-the-art PLC controller, the M15 automates the entire heat transfer process, ensuring consistent results with minimal manual intervention. This reduces labor costs and eliminates human error.

Laser Positioning System: The integrated laser positioning ensures precise alignment for every mug, minimizing waste and guaranteeing flawless sublimation transfers.

High-Efficiency Design: Built for 11oz and 15oz sublimation mugs, the M15’s smart dual heating technology delivers even heat distribution, ensuring vibrant, long-lasting designs.

Robust and Reliable: Backed by Microtec’s 23 years of expertise, the M15 offers a two-year warranty, a five-year warranty on the heating plate, and lifetime technical support, ensuring long-term reliability.

The M15 is more than just a heat press—it’s a strategic investment for businesses looking to scale. Its fully automatic operation and high output make it perfect for:

Print-on-Demand Stores: Seamlessly handle bulk orders for custom mugs with quick turnaround times.

Promotional Product Manufacturers: Meet tight deadlines with consistent, high-quality results.

Sublimation Studios: Achieve professional-grade transfers with zero wrinkles and perfect alignment.

By integrating the M15 with Microtec’s MWM-10 Automatic Mug Wrapping Machine, businesses can create a fully automated workflow, further reducing labor costs and boosting efficiency. This combination is a game-changer for POD sellers looking to expand their product offerings and stay competitive.

Microtec’s M15 15-Station Fully Automatic Heat Transfer Mug Press is the ultimate solution for businesses aiming to dominate the personalized gift and sublimation markets. With its high-speed production, robotic automation, and precision engineering, the M15 empowers businesses to scale efficiently while delivering flawless results.

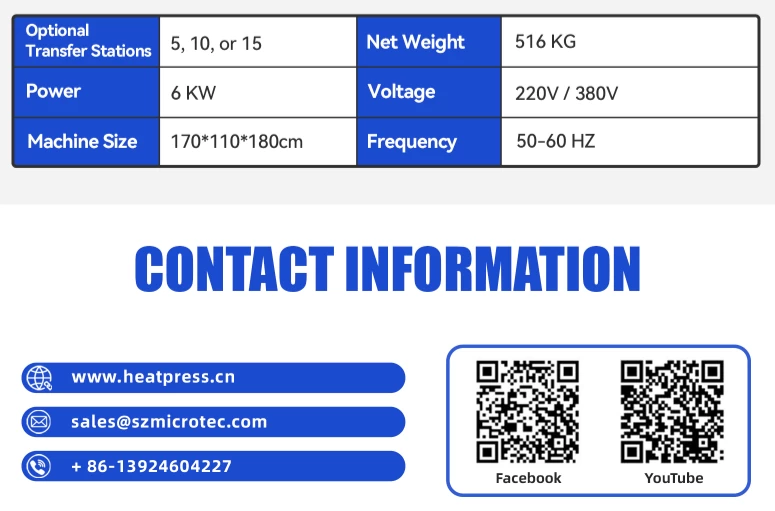

Visit www.heatpress.cn to explore the M15 and discover how Microtec’s 23 years of heat transfer expertise can elevate your production capabilities.