Welcome to the world of heat press machines, where technology meets creativity! If you're looking for a reliable, efficient, and high-quality heat press machine, you've come to the right place. Today, we're diving into the Microtec Fully Automatic Heat Press Machine, specifically the enhanced APD Series Pneumatic High-Pressure Heat Press. This machine is designed for superior performance in professional heat transfer applications, making it ideal for T-shirts, garments, fabrics, and more. Ready to explore? Let's get started!

Understanding the APD Series Pneumatic High-Pressure Heat Press

What is the APD Series?

The APD Series is a line of fully automatic heat press machines by Microtec, engineered to deliver consistent high pressure and precision. These machines are a game-changer for anyone serious about professional heat transfer applications.

Why Choose Pneumatic High-Pressure?

Pneumatic high-pressure systems use air pressure to ensure consistent and precise pressure application. This is crucial for achieving high-quality prints, especially when working with intricate designs or thick fabrics.

Key Features of the APD Series Heat Press

Fully Draw-Out Mechanism

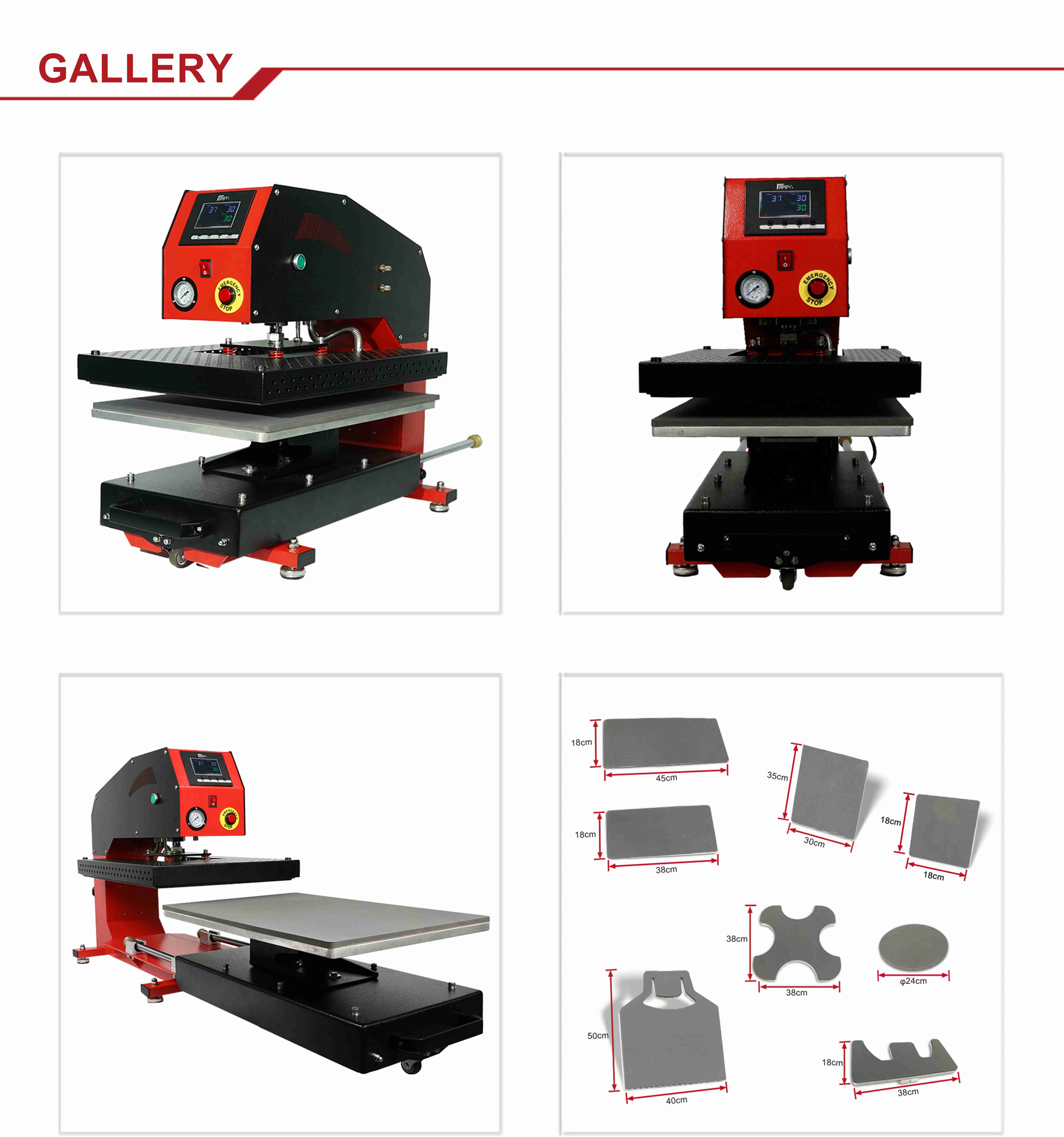

One of the standout features of the APD Series is the fully draw-out mechanism. This allows for easy loading and unloading of materials, enhancing both safety and efficiency. Imagine not having to struggle with awkward placements—just slide the lower platen out, position your item, and slide it back in. It's that simple!

Consistent High Pressure

Consistency is key in the world of heat transfer, and the APD Series delivers just that. With its pneumatic high-pressure system, you can be sure that every press will have uniform pressure across the entire surface. This is vital for ensuring your prints are of the highest quality, free from any uneven spots.

Full Threadability

What is full threadability, you ask? It's the ability to position and align garments such as T-shirts, hoodies, and sweatshirts easily. This feature makes the APD Series incredibly versatile, allowing you to tackle a wide range of projects without any hassle.

Large Space for Projects

Whether you're working on small items or bulky garments, the APD Series has got you covered. It comes in two sizes: 16"x20" and 16"x24". This ample space allows you to handle various heat transfer projects with ease, accommodating both small and large items.

Precision Temperature Control

Achieving high-quality results requires precise temperature settings. The APD Series ensures consistent heat application, essential for different substrates. Whether you're working with delicate fabrics or sturdy materials, you can trust the APD Series to deliver the perfect amount of heat.

User-Friendly Interface

Despite its advanced features, the APD Series is designed with an intuitive interface. This makes it easy for both beginners and professionals to operate. No more fumbling with complicated settings—just straightforward, user-friendly controls.

Efficiency and Speed

In the fast-paced world of printing, time is money. The APD Series is highly efficient, allowing users to complete more projects in less time. Its automatic features and high-pressure capability maximize productivity, so you can focus on what matters most: creating amazing prints.

Durability and Reliability

Built with high-quality materials, the APD Series is designed for durability and reliability. This means you can count on it for long-term value and consistent performance, making it a worthy investment for any professional.

Applications of the APD Series Heat Press

Ideal for T-Shirts, Garments, and Fabrics

The APD Series is perfect for printing on T-shirts, garments, and fabrics. Whether you're creating custom apparel, sportswear, or promotional items, this machine delivers exceptional results every time.

Customizing Apparel and Sportswear

From team jerseys to personalized hoodies, the APD Series makes customizing apparel a breeze. Its precision and versatility ensure that every piece you create is unique and of the highest quality.

Creating Promotional Items

Promotional items are a great way to market your brand, and the APD Series is the perfect tool for the job. With its ability to handle various materials and sizes, you can create a wide range of promotional products that stand out.

Why the APD Series Stands Out?

Comparing with Other Heat Press Machines

When it comes to heat press machines, the APD Series stands out for its advanced features and superior performance. While other machines may offer similar capabilities, the APD Series combines them all into one efficient and reliable package.

Testimonials and Reviews

Don't just take our word for it—hear what others have to say! Users rave about the APD Series, praising its ease of use, consistent results, and overall performance. It's clear that this machine is a favorite among professionals in the heat transfer industry.

How to Get Started with the APD Series Heat Press

Setting Up Your Machine

Getting started with the APD Series is a breeze. Simply follow the setup instructions provided, and you'll be ready to go in no time. Make sure to familiarize yourself with the user manual to get the most out of your machine.

Tips for First-Time Users

If you're new to heat pressing, don't worry! The APD Series is designed with beginners in mind. Here are a few tips to help you get started:

Maintenance and Care for Longevity

Routine Maintenance Tips

To keep your APD Series heat press in top condition, regular maintenance is key. Here are a few tips:

Troubleshooting Common Issues

Even the best machines can encounter issues. If you run into any problems with your APD Series heat press, here are some common troubleshooting tips:

Conclusion

In summary, the Microtec Fully Automatic Heat Press Machine, specifically the APD Series Pneumatic High-Pressure Heat Press, is a top choice for anyone serious about professional heat transfer applications. Its advanced features, ease of use, and consistent performance make it a valuable investment. Whether you're a beginner or a seasoned pro, the APD Series will help you achieve superior results every time.

FAQs

What materials can I use with the APD Series heat press?

The APD Series is versatile and can handle a wide range of materials, including T-shirts, hoodies, sweatshirts, and other fabrics.

How do I ensure consistent pressure for my projects?

The APD Series uses a pneumatic high-pressure system to ensure uniform pressure across the entire surface, resulting in high-quality prints every time.

Can the APD Series handle bulk orders?

Absolutely! The efficiency and speed of the APD Series make it perfect for handling bulk orders, maximizing your productivity.