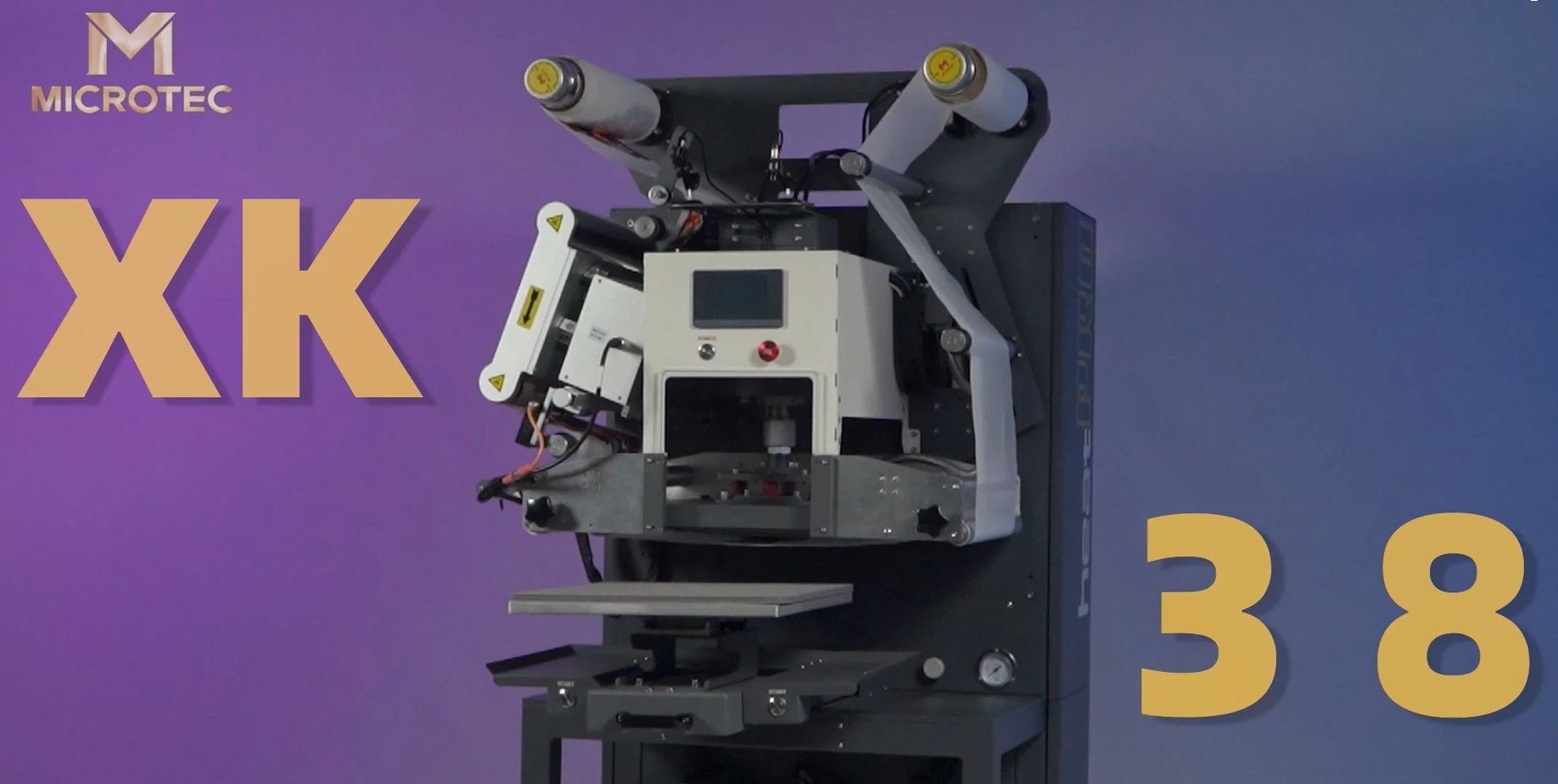

Revolutionize Your Heat Transfer Production with the XK-38 RotaryHeat Pro

Struggling with slow production, material waste, or alignment errors in your heat transfer business? The XK-38 RotaryHeat Pro by Microtec is engineered to solve these challenges with smart automation, precision, and unmatched efficiency—helping businesses scale faster while cutting labor costs.

Traditional heat presses require constant cutting and reloading, wasting time and transfer film. The XK-38’s Smart Roll Continuous Transfer ensures 100% material utilization with zero cutting, reducing costs and boosting output.

Manual alignment leads to errors and reprints. With Vision Lock Auto-Alignment, the XK-38 achieves 0.3mm precision—even at 100+ garments/hour—ensuring flawless transfers every time.

Switching between large (15”×15”) and small (6”×6”) transfers usually means stopping production. The Instant-Swap Platens let you change sizes in under 30 seconds, maximizing uptime.

From auto-loading to foot-controlled ejection and film recycling, the XK-38 minimizes manual labor, allowing operators to focus on quality control and scaling production.

✔ 40% Faster Cycles – Higher output vs. traditional presses

✔ Auto-Film Collector – 5X faster setup for continuous runs

✔ Safety-Enhanced Design – IR positioning & emergency stop for accident-free operation

Upgrade to Smarter Heat Transfer Today!